Date: 2026-01-13

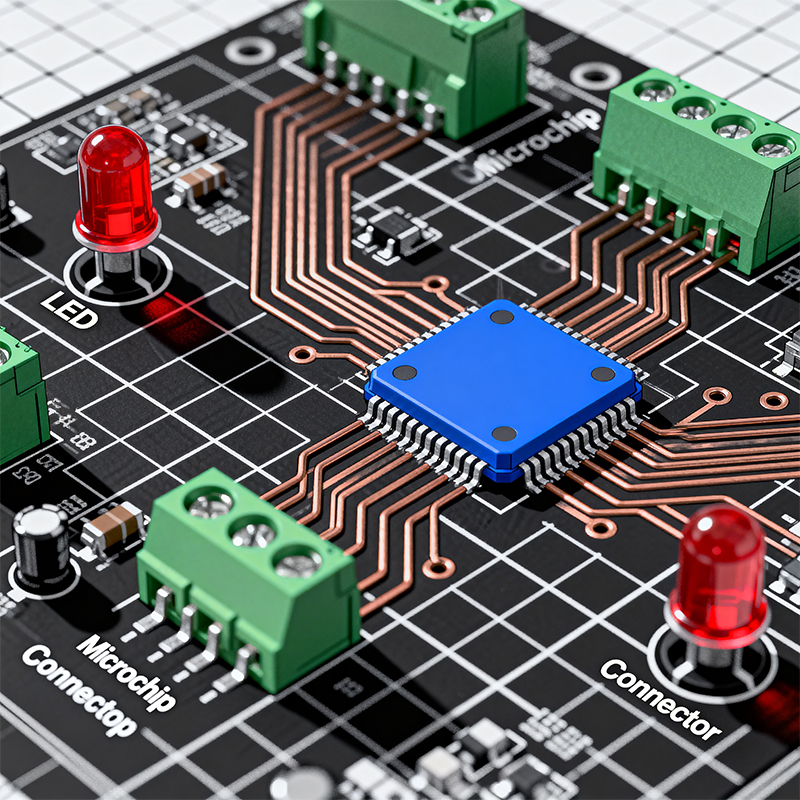

You know the feeling. The circuit simulates perfectly, the PCB layout looks clean, and the components on your BOM are all top-shelf. But when they all show up at the factory to get assembled, something feels… off.

It's not that any one piece is broken. It's that they don't quite fit together the way you imagined. That slight unease is what drives people to search for answers about electronic components pcb. It’s the search for how to make the marriage between your parts list and your board design actually work in practice, not just in theory.

Think of it like cooking a complex meal. You can have the world's best recipe (your schematic) and buy premium ingredients (your components), but if your pan (the PCB) is the wrong size or material, and you don't have a good process for combining everything, the result is disappointing.

The trouble often starts in the tiny gaps—the spaces between what the datasheet promises, what your CAD software assumes, and what the assembly machine can actually do.

The "Looks Right, Feels Wrong" Component: You've picked a perfect little chip. Its footprint in your CAD library is technically correct. But on the actual PCB, the solder paste doesn't flow perfectly under its thermal pad during reflow, leaving a hidden void. The board looks assembled, but the chip overheats and fails. The issue wasn't the chip or the board alone; it was the specific interaction between that chip's package and your board's pad design and assembly process.

The Supply Chain Ghost: Your PCB is ready in two weeks. Your perfect microcontroller? The distributor just updated the lead time to "30+ weeks." Now your beautiful, custom board is a very expensive paperweight, waiting for one single part. The timelines for your components and your PCB are completely out of sync.

The Blame Game: When a board fails test, the conversation can go in circles. "It must be a counterfeit component," says one person. "The soldering profile was wrong," says another. "The PCB pad finish is out of spec," claims a third. You're stuck in the middle, trying to diagnose a problem that exists in the handoffs between different specialists.

A lot of headaches come from thinking about components and PCBs as two separate projects. First, you design the board. Then, you buy parts that fit on it. Then, you hope someone can put them together.

A more fluid approach is to think about the complete system from the start. This means asking different questions much earlier:

"Is this amazing component actually available and reliable to source for the next two years, or is it about to be discontinued?"

"Does our board design not just fit this part, but is it easy for a machine to place and solder it reliably, thousands of times?"

"If this part becomes unavailable, is there a drop-in alternative, or does it require a full PCB redesign?"

When you manage to align components and PCB seamlessly, the process feels different. It's less about frantic problem-solving and more about steady execution.

It often starts with a collaborative review—not after problems appear, but before the first purchase order is cut. A manufacturer with experience looks at your BOM and your board files together and spots the potential friction points. They might say:

"We see you're using that connector. It's a good one, but it's notoriously hard to solder without bridging on dense boards. We can adjust the stencil design here to compensate, or we know a similar part that's more assembly-friendly."

"Your design uses several parts from the same family that are on allocation. We can source them, but it's a risk. Here are some equally good alternates with better supply, and their footprints are compatible."

"The clearance around this large IC is tight. Our AOI camera won't be able to inspect these side capacitors. Can we nudge them over 0.2mm?"

This isn't criticism. It's the practical wisdom of manufacturing, applied early enough to actually help. It closes the gaps before they become expensive problems.

For teams tired of managing the disconnect, the solution isn't a better spreadsheet. It's often a better partner. You need someone who doesn't just receive your parts and boards, but who understands the entire journey from your design screen to a working assembled unit.

Look for a partner who asks questions about your component choices in relation to your board, who has direct visibility into component markets, and who takes ownership of the final assembled quality. Their goal should be to make the complex dance between your electronic components and your PCB look simple and predictable.

At the end of the day, the magic of electronics happens not in the component tray or the bare board, but in the reliable, high-quality connection between them. Finding a way to orchestrate that connection smoothly is what turns a good design into a great product.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..