Date: 2026-01-15

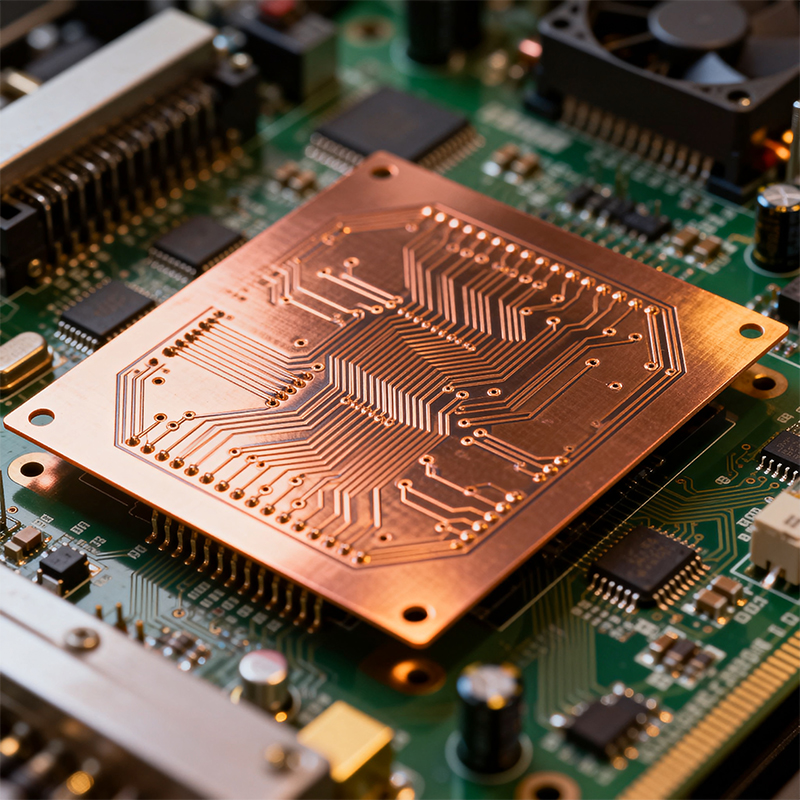

If you open up any electronic device and see that green (or other colored) circuit board, its most fundamental material is copper clad laminate. But do you really understand this seemingly simple material? It's like the foundation of a house—it determines the entire structure's stability and lifespan.

Simply put, copper clad laminate is an insulating substrate material covered with copper foil on one or both sides, bonded together firmly through a hot-pressing process. You can think of it as a "sandwich":

Top layer: Copper foil (conductive layer)

Middle layer: Insulating substrate (support layer)

Bottom layer: Copper foil (conductive layer)

This "sandwich" is the starting point for all printed circuit boards. When we etch away unwanted copper from this base, leaving behind the designed circuit pattern, we get the familiar PCB.

Copper foil isn't ordinary copper sheet—it's an extremely thin copper layer produced through electrolysis or rolling processes, typically ranging from 0.5 oz to 2 oz (approximately 18 to 70 microns). To put that in perspective, a human hair is about 70 microns in diameter, so the thinnest copper foil is finer than a hair strand.

The surface treatment of copper foil is also crucial. Proper roughness improves bonding with the substrate, but excessive roughness affects high-frequency signal transmission—it's like setting appropriate friction on a highway: not too slippery, not too rough.

The substrate determines most of the circuit board's performance:

The Most Common: FR-4 Material

This is a composite made from glass fiber cloth impregnated with epoxy resin. Its popularity stems from its good balance of mechanical strength, electrical properties, cost, and processability. However, "FR-4" is actually a broad category, with significant variations in formulations between manufacturers.

Specialty Substrates:

High-frequency materials: For 5G, radar, and other high-frequency applications, typically with more stable dielectric constants

High thermal conductivity materials: For high-heat applications like LED lighting and power modules

Flexible substrates: Polyimide film for bendable flexible circuits

Metal-core substrates: Aluminum-based boards with excellent heat dissipation

Special adhesives are needed between the copper foil and substrate. These must remain stable under high temperatures and humidity while offering good insulation and chemical resistance.

The most common type, like a rigid sheet. Classified by reinforcing material:

Paper-based: Lowest cost, used in consumer electronics

Glass cloth-based: Better performance, for most industrial products

Composite-based: Mix of paper and glass cloth, balancing cost and performance

Uses polyimide film as substrate, capable of bending thousands of times without damage. Your laptop screen connectors and foldable phone internal connections use this material.

Metal-core: Directly bonded to aluminum or copper plates, excellent for heat dissipation

High-frequency: Very stable dielectric constant and loss factor, suitable for high-speed signals

High Tg: Remains stable at higher temperatures, suitable for lead-free soldering processes

Think of it as the temperature where material changes from "glassy" to "rubbery." Standard FR-4 has a Tg around 130°C, mid-range about 150°C, and high Tg above 170°C. Higher Tg means better heat resistance and less deformation during soldering.

These are crucial for high-frequency circuits:

Dk affects signal propagation speed

Df determines energy loss during signal transmission

Standard FR-4 performance degrades at high frequencies

How much material expands when heated. Ideally, CCL's thermal expansion should match copper foil's; otherwise, temperature changes can cause separation between layers.

Measures how firmly copper foil bonds to the substrate. Too weak causes peeling; too strong makes intentional removal difficult.

Making copper clad laminate is a precise process:

Resin preparation: Mixing resin, hardeners, fillers per formula

Impregnation: Passing glass cloth through resin bath for thorough saturation

Drying: Removing solvents to produce "prepreg"

Lamination: Stacking copper foil and prepreg, curing under heat and pressure

Post-processing: Cutting, testing, packaging

This sounds straightforward, but each step requires tight control. A few degrees temperature variation or slight pressure changes can affect final product performance.

When selecting CCL for your project, consider this decision process:

What frequencies will your product operate at?

What's the operating temperature range?

What mechanical stress must it withstand?

What's the cost budget?

Consumer electronics: Usually standard FR-4, focus on cost

Automotive electronics: Require high Tg, high reliability materials

Communication equipment: May need high-frequency materials

Power products: Focus on thermal conductivity and voltage withstand

What materials is your PCB manufacturer familiar with?

Is the material suitable for your design (multilayer, HDI, etc.)?

Is material supply stable?

Few materials excel in all aspects. You'll typically trade off between performance, cost, and availability. For example, high-frequency materials perform better but cost more, while standard FR-4 costs less but has limited high-frequency performance.

Imagine designing a home router:

It handles Wi-Fi signals (2.4GHz and 5GHz) → needs good high-frequency performance

Generates heat during prolonged operation → requires decent heat resistance

Cost-sensitive → can't use expensive materials

In this case, you might choose mid-Tg FR-4 material, possibly using better-performing material only in critical high-frequency areas while using standard material elsewhere—this "hybrid use" strategy is common in engineering.

Lower loss materials for 5G and future communications

More environmentally friendly halogen-free materials

Higher thermal conductivity materials for increasing power demands

Thinner copper foils (below 12 microns) for finer lines

Better dimensional stability for higher density designs

Improved heat resistance for lead-free soldering requirements

More manufacturers focus on material recyclability and environmental friendliness, changing material formulations and manufacturing processes.

Copper clad laminate might not be as attention-grabbing as chips, but it's the foundation of the entire electronics industry. Just as you wouldn't build a skyscraper on sand, without proper CCL, even the most sophisticated circuit design can't be realized.

Understanding CCL basics not only helps you choose the right material but also helps avoid potential issues during the design phase. After all, a good start is half the battle, and good CCL is exactly that "good start."

About us: Kaboer is a PCBA company with its own manufacturing factory located in Shenzhen, China. We handle PCB designs using various copper clad laminates daily. If you have questions about material selection for a specific project, we're happy to share our practical experience.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..