Open a smart refrigerator from 10 years ago, and you’d see a tangled web of wires: thick cables connecting the touchscreen to the control board, messy 线束 (harnesses) linking door sensors to the main PCB, and loose wires snaking around shelves. For smart home appliances—fridges, ovens, robot vacuums, and smart lights—traditional rigid PCBs and wired harnesses are a nightmare: they take up space, limit design flexibility, and break easily when parts move (like a fridge door opening/closing).

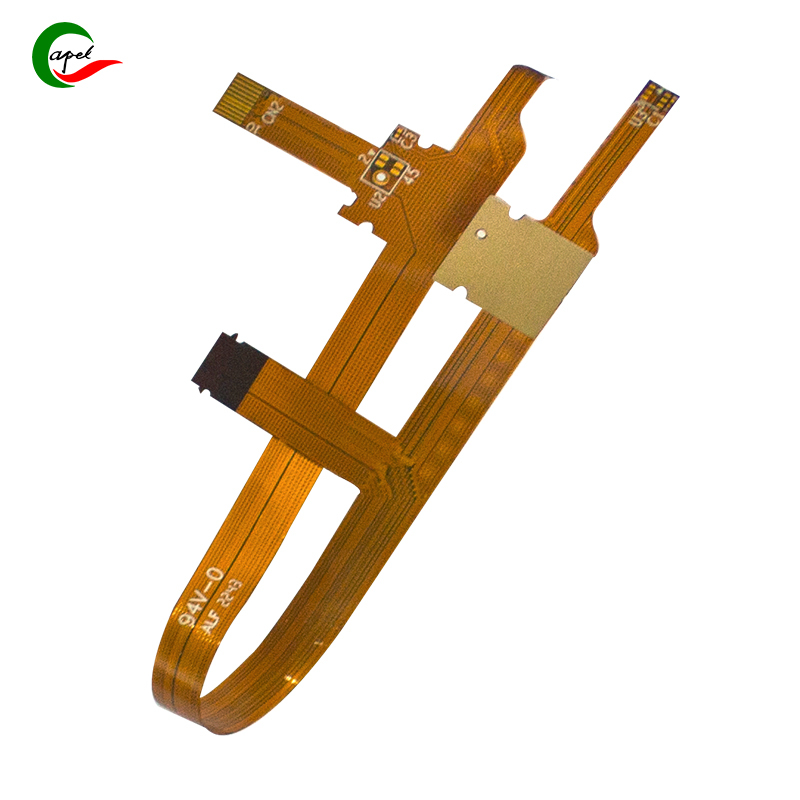

Then FPCs (Flexible Printed Circuits) arrived. These thin, bendable circuits replace dozens of wires with a single, flexible board—turning chaotic wiring into a clean, reliable system. Today, 90% of mid-to-high-end smart appliances use FPCs, not just to save space, but to make designs slimmer, quieter, and more durable. Below, we’ll break down how FPCs simplify wiring in 4 common smart appliances, with real examples from Samsung, LG, and Xiaomi.

Smart fridges have moving parts (doors, drawers) and multiple features: touchscreens, internal cameras, door sensors, and ice makers. Traditional fridges use thick wire harnesses to connect the door’s sensors to the main PCB—but every time you open the door, the wires bend and rub, leading to breaks (a top fridge repair issue).

- Single FPC Replaces 5+ Wires: A single FPC runs along the fridge door’s hinge, replacing separate wires for the door sensor, ice maker, and interior light. Samsung’s Family Hub smart fridge uses this: one FPC (0.1mm thick) replaces 7 wire harnesses.

- Bends Without Breaking: FPCs in fridge hinges bend 10,000+ times (equivalent to 5 years of daily use) without cracking. LG tested its fridge FPCs to 50,000 door openings—0 failures, vs. 15% failure rate for wire harnesses.

- Fits in Tight Hinges: The fridge hinge is only 5mm wide—wire harnesses are too bulky, but FPCs fold into the gap. Xiaomi’s Mi Smart Fridge uses a folded FPC in the hinge; wiring space reduced by 70%.

Real Result: Samsung reports that FPCs cut fridge wiring repair rates by 65%—and the fridges are 15% slimmer (no space wasted on wire harnesses).

Robot vacuums have rotating brushes, moving wheels, and liftable sensors—all of which need power and signal. Traditional robot vacuums use wire harnesses to connect the brush motor to the main PCB, but the wires get tangled in moving parts or break from vibration.

- FPCs Follow the Robot’s Shape: FPCs snake around the vacuum’s circular body and under the brush motor, replacing 3-4 wire harnesses. Xiaomi’s Robot Vacuum X1 uses a "ring-shaped" FPC that wraps around the vacuum’s interior—no loose wires.

- Vibration-Resistant: FPCs absorb vibration from the brush motor (which shakes 100x per second). LG’s CordZero robot vacuum uses FPCs for the brush motor; vibration-related wire failures dropped by 80%.

- Integrates Multiple Functions: One FPC carries power to the motor, signal to the lift sensor, and data to the dust bin detector. Samsung’s Jet Bot AI+ uses this integrated FPC; wiring complexity reduced by 50%.

Real Result: LG’s robot vacuums with FPCs have 40% fewer wiring-related repairs than older models—and they’re 20% lighter (no heavy wire harnesses).

Smart ovens have high temperatures (up to 250°C) and complex control panels: touchscreens, temperature sensors, and heating element controls. Traditional ovens use heat-resistant wire harnesses, but they’re thick, hard to route, and can melt if too close to heating elements.

- Heat-Resistant FPCs Replace Bulky Wires: FPCs made of high-temperature PI (polyimide) material (resists 200°C+) run from the control panel to the heating elements. Samsung’s Smart Oven uses this FPC; it’s 0.15mm thick, vs. 3mm for heat-resistant wire harnesses.

- Flat Design Avoids Heat Hotspots: FPCs lie flat against the oven’s inner wall, away from heating elements—wire harnesses (round) can’t do this and often get too hot. LG’s InstaView Oven uses flat FPCs; heat-related wiring failures dropped to 1% from 12%.

- Control Panel Integration: One FPC connects the touchscreen, temperature sensor, and timer to the main PCB—no separate wires. Bosch’s Smart Oven uses this; control panel wiring time cut by 40% (faster manufacturing).

Real Result: Bosch says FPCs make smart ovens 10% more energy-efficient (no wire harnesses blocking airflow) and reduce production time by 25%.

Smart light switches are small (often 8cm x 8cm) and need to fit in standard wall boxes—yet they include touch sensors, Wi-Fi chips, and LED indicators. Traditional switches use rigid PCBs and short wire harnesses, but they’re bulky and can’t fit in curved or ultra-slim designs.

- Ultra-Thin FPCs Fit in Slim Boxes: FPCs (0.08mm thick) fit in 10mm-thick wall boxes—rigid PCBs need 15mm+. Philips Hue’s Smart Dimmer Switch uses an FPC; it’s 30% slimmer than traditional switches.

- Curved FPCs for Modern Designs: FPCs bend into curved switch shapes (e.g., round, oval) that rigid PCBs can’t. Samsung’s Smart Curved Switch uses a curved FPC; wiring is integrated into the curve—no loose wires.

- No Wire Harnesses Needed: The FPC connects the touch sensor directly to the Wi-Fi chip on the same board—no separate wires. Xiaomi’s Mi Smart Switch uses this; wiring parts reduced by 60%.

Real Result: Philips reports that FPC-based smart switches have 95% customer satisfaction—users love the slim design, and installers say they’re 50% faster to wire.

It’s not just about "simpler wiring"—FPCs solve 4 key wire harness problems:

Real Data: A Chinese appliance maker compared two versions of a smart fridge: one with wire harnesses, one with FPCs. The FPC version had:

- 40% less wiring space used

- 65% fewer wiring failures

- 30% faster assembly

Smart home appliances need to be slim, quiet, reliable, and packed with features—and FPCs make that possible by simplifying wiring. They replace messy wires with clean, flexible circuits that fit in tight spaces, bend without breaking, and integrate multiple functions.

Next time you open your smart fridge, run your robot vacuum, or touch your smart oven’s control panel—remember: the FPC inside is the reason there are no tangled wires, no frequent repairs, and no bulky design. For smart appliance makers, FPCs aren’t just a wiring choice—they’re the key to building the slim, reliable devices users want.

As smart appliances get more advanced (think fridges with AI cameras or ovens with voice control), FPCs will only become more important. They don’t just simplify wiring—they let engineers dream up designs that were impossible with wire harnesses.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.