Date: 2025-10-22

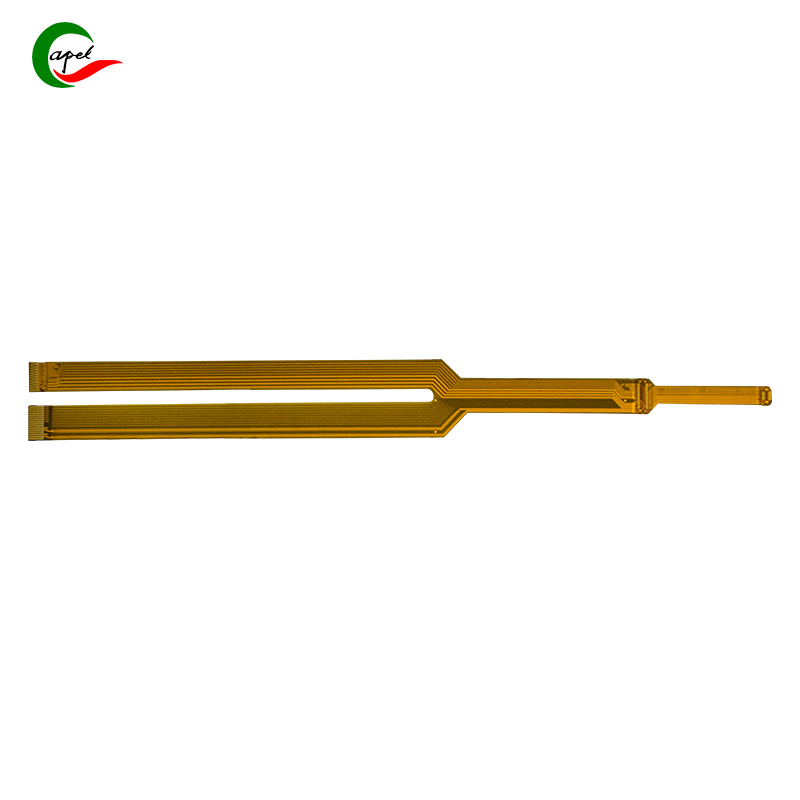

If you've ever held a modern portable ultrasound device or worn a continuous glucose monitor, you've witnessed firsthand how flexible PCBs are transforming medical technology. I remember working with a startup developing a cardiac monitor - we hit a wall with rigid PCBs until we switched to flexible solutions. The difference wasn't just incremental; it was transformational.

Medical devices face constraints that would challenge any electronics designer. During a project for a wearable ECG monitor, we discovered that patients would abandon devices that were too bulky or uncomfortable. The rigid PCB we initially used created pressure points that affected both comfort and signal quality.

The Disinfection Dilemma

Medical environments demand reliability through extreme conditions. I've tested devices that needed to survive hundreds of disinfection cycles. Traditional rigid PCBs failed at the solder joints after repeated exposure to alcohol wipes and autoclave cycles. The thermal expansion mismatch between components and substrate created cracks that were invisible until the device stopped working.

Anatomical Compatibility

Human bodies aren't flat, but rigid PCBs are. This fundamental mismatch causes real problems. In one project for a wound monitoring system, the rigid PCB prevented the device from conforming properly to curved body surfaces, leading to poor sensor contact and unreliable data.

Space Transformation

The thickness advantage of flexible PCBs is dramatic. We recently helped redesign a portable diagnostic device that went from 25mm to 12mm thick simply by switching to flexible PCBs. The space savings allowed for a larger battery while making the device truly pocket-sized.

Reliability Through Flexibility

Properly designed flexible PCBs handle mechanical stress much better than their rigid counterparts. We've tested wearable devices through thousands of bend cycles simulating daily use. The key is designing the bend areas to work with the device's mechanical requirements rather than against them.

Chemical Resistance That Matters

Medical-grade polyimide stands up to harsh disinfectants that would destroy standard PCB materials. We specify materials that meet ISO 10993 standards and test them against actual medical disinfectants to ensure long-term reliability.

Wearable Monitoring Revolution

Continuous health monitoring requires devices people will actually wear. We designed a flexible PCB for a cardiac patch monitor that patients could wear for weeks without discomfort. The conformable design maintained consistent electrode contact, improving signal quality by over 30% compared to rigid designs.

Minimally Invasive Advances

In endoscopic applications, flexible PCBs enable designs that were previously impossible. We worked on a surgical tool that used a flexible PCB running through a 3mm diameter shaft. The flexibility allowed the tool to articulate while maintaining signal integrity for HD video transmission.

Portable Diagnostics

The shift to point-of-care diagnostics demands smaller, lighter equipment. We helped transform a 5kg ultrasound unit into a 1.2kg handheld device using flexible PCBs. The weight reduction wasn't just about convenience - it made the technology accessible in remote clinics and emergency settings.

Material Selection is Critical

Not all flexible PCB materials are suitable for medical use. We've learned to:

Specify medical-grade polyimide with proven biocompatibility

Use rolled copper for dynamic flexing applications

Select solder masks that withstand repeated chemical exposure

Design for Reliability

Medical devices can't fail when lives depend on them. Our design approach includes:

Routing critical signals along the neutral axis

Using gradual transitions between rigid and flexible areas

Implementing redundant connections for critical circuits

Testing Beyond Specifications

Medical applications require more rigorous testing than commercial products. We subject designs to:

Accelerated aging with medical disinfectants

Mechanical testing simulating years of use

Environmental testing across clinical temperature ranges

Balancing Flexibility and Durability

Early in our medical work, we faced failures in areas that flexed repeatedly. The solution came from understanding exactly how and where the device would bend, then reinforcing other areas while maintaining flexibility where needed.

Managing Thermal Issues

Medical devices often need to operate in challenging thermal environments. We've developed strategies for heat dissipation in compact flexible designs, using thermal vias and strategic component placement.

Ensuring Signal Integrity

High-quality medical data requires clean signals. We've implemented techniques to maintain signal integrity in flexible circuits, including careful impedance control and shielding strategies.

The data from clinical use is compelling:

Patient compliance with wearable monitors increased by 40% when devices became more comfortable

Diagnostic accuracy improved with better sensor contact

Device reliability in clinical settings increased significantly

One hospital system reported a 60% reduction in device failures after switching to flexible PCB designs in their monitoring equipment.

The technology continues to evolve. We're working on:

Stretchable circuits for next-generation wearables

Integrated sensors in flexible substrates

Even thinner profiles for implantable applications

Flexible PCBs have moved from being an alternative to rigid boards to becoming the foundation of modern medical device innovation. The ability to create devices that are smaller, more reliable, and more comfortable while meeting stringent medical requirements has opened up new possibilities in healthcare.

For engineering teams working on medical devices, embracing flexible PCB technology isn't just about keeping up with trends - it's about creating better solutions for patients and healthcare providers. The companies that master this technology will be the ones shaping the future of medical devices.

The transition to flexible PCBs in medical devices represents more than just a technical improvement - it's enabling a fundamental shift toward more accessible, reliable, and patient-friendly healthcare technology.

related link:

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..