Date: 2025-10-22

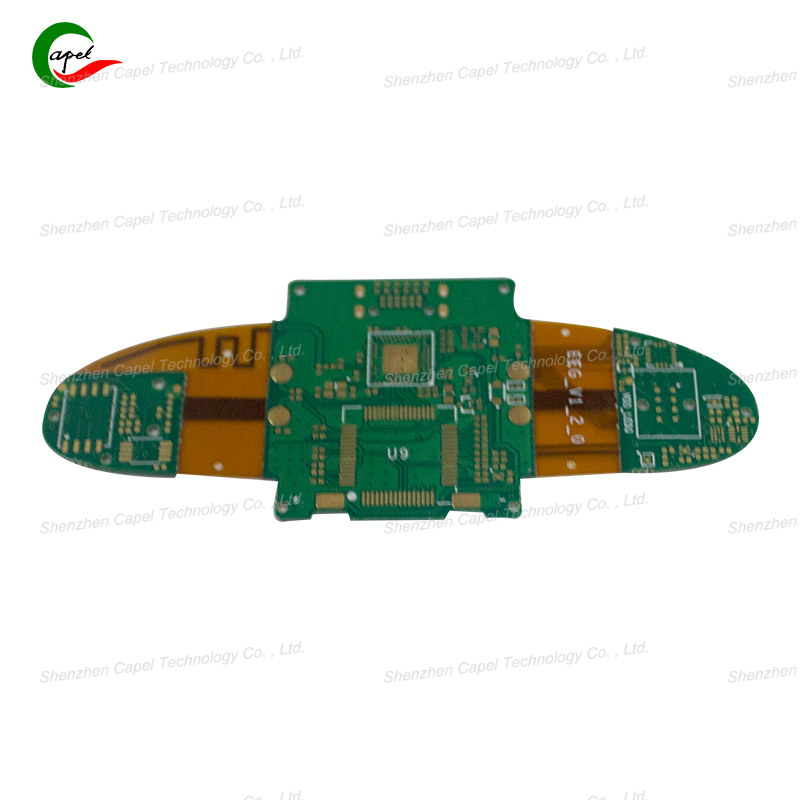

If you've ever torn down a high-end drone like the DJI Mavic 3, you'll notice something interesting about the internal electronics - the extensive use of rigid-flex PCB technology. This isn't accidental. After working with several drone manufacturers on weight reduction initiatives, I've seen how rigid-flex PCBs transform drone performance in ways that traditional wiring simply can't match.

Every gram matters in drone design. I remember working with an agricultural drone company where we managed to reduce the wiring harness weight from 68 grams to 32 grams by switching to rigid-flex PCBs. That 36-gram reduction translated to an additional 4 minutes of flight time - significant when you're covering thousands of acres.

The Integration Bottleneck

Modern drones pack an incredible amount of electronics into tight spaces. In one foldable drone project, we had to fit flight controllers, GPS modules, obstacle avoidance sensors, and camera systems into arms that were only 25mm wide. Traditional wiring harnesses would have been impossible to route cleanly.

Vibration: The Silent Killer

Drones operate in harsh vibration environments. I've analyzed flight data showing vibration levels reaching 20g during aggressive maneuvers. These conditions quickly destroy traditional PCB connections and cable assemblies.

Weight Reduction That Matters

The numbers tell the story. A typical rigid-flex implementation can reduce wiring weight by 40-60% compared to traditional approaches. But the real benefit comes from what you can do with those savings - larger batteries, additional sensors, or simply longer flight times.

Space Optimization

The ability to create three-dimensional circuit layouts is revolutionary for drone design. We recently designed a rigid-flex board that wrapped around the internal structure of a drone arm, saving 65% of the space that would have been needed for conventional PCBs and wiring.

Vibration Resistance

Through accelerated testing, we've verified that properly designed rigid-flex assemblies can withstand vibration profiles that would destroy traditional wiring in hours. The key is managing the transition between rigid and flexible sections.

Material Selection for Flight Conditions

Through extensive testing, we've found that certain materials work particularly well for drone applications:

LCP substrates for high-frequency applications like FPV racing drones

25μm polyimide for most consumer drone applications

18μm rolled copper for optimal flex endurance

Design Strategies That Work

The transition zones between rigid and flexible sections require special attention. We use:

3-5mm tapered transitions for high-stress areas

Strategic stiffeners near component clusters

Careful management of bend radii

Manufacturing Considerations

Drone applications demand both precision and reliability. We work with manufacturers who specialize in:

Laser cutting with tight tolerances

Advanced inspection techniques

Rigorous testing protocols

The results from production drones demonstrate the impact:

Flight time improvements of 15-30% through weight reduction

Reliability improvements of 40-60% in vibration testing

Assembly time reductions of 25-35%

One industrial drone manufacturer reported a 73% reduction in field failures after switching to rigid-flex PCBs in their motor control systems.

Thermal Management

Early designs struggled with heat dissipation in compact spaces. We've developed solutions using:

Thermal vias in rigid sections

Strategic component placement

Advanced thermal interface materials

Signal Integrity

Maintaining signal quality in flexible sections requires careful design. We implement:

Controlled impedance design

Proper grounding strategies

Shielding where necessary

Start with High-Value Applications

We typically begin with:

Flight controller assemblies

Motor control circuits

Camera and gimbal systems

Prototype and Test Early

Physical testing is crucial. We recommend:

Vibration testing simulating actual flight conditions

Thermal cycling across expected operating ranges

Mechanical endurance testing

The technology continues to evolve. We're currently working on:

Even thinner flexible sections

Integrated antenna systems

Advanced thermal management solutions

Rigid-flex PCBs have moved from being a specialty solution to a fundamental enabling technology for high-performance drones. The weight savings, space optimization, and reliability improvements they provide are essential for meeting the demanding requirements of modern drone applications.

For engineering teams working on next-generation drones, mastering rigid-flex design isn't just beneficial - it's becoming essential for creating competitive products. The companies that embrace this technology today will be the ones setting the performance standards tomorrow.

The transition to rigid-flex PCBs represents more than just a component change - it enables fundamentally better drone designs that push the boundaries of what's possible in terms of flight time, reliability, and capability.

related link:

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..