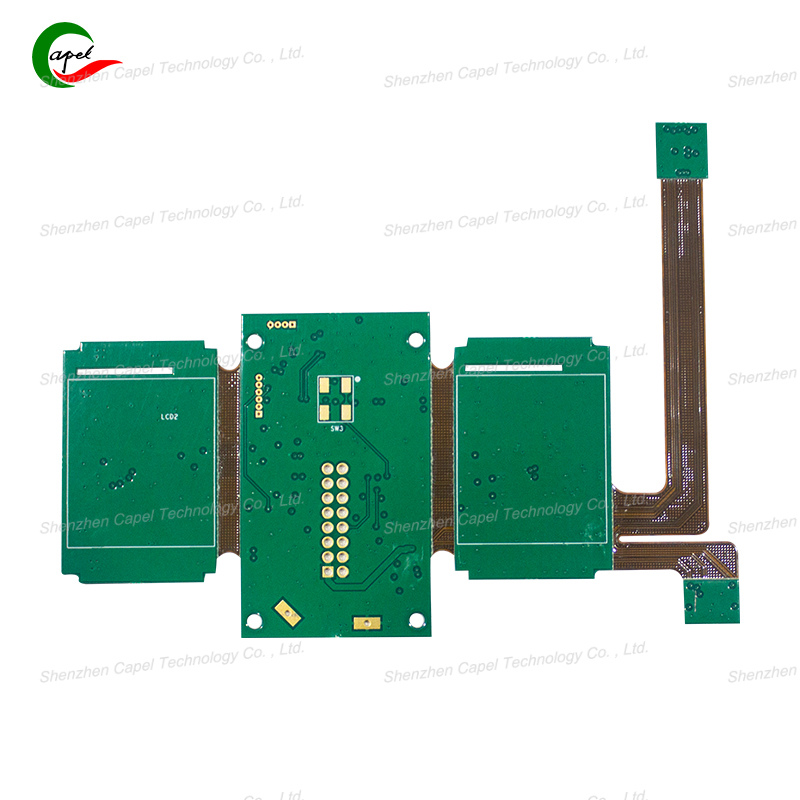

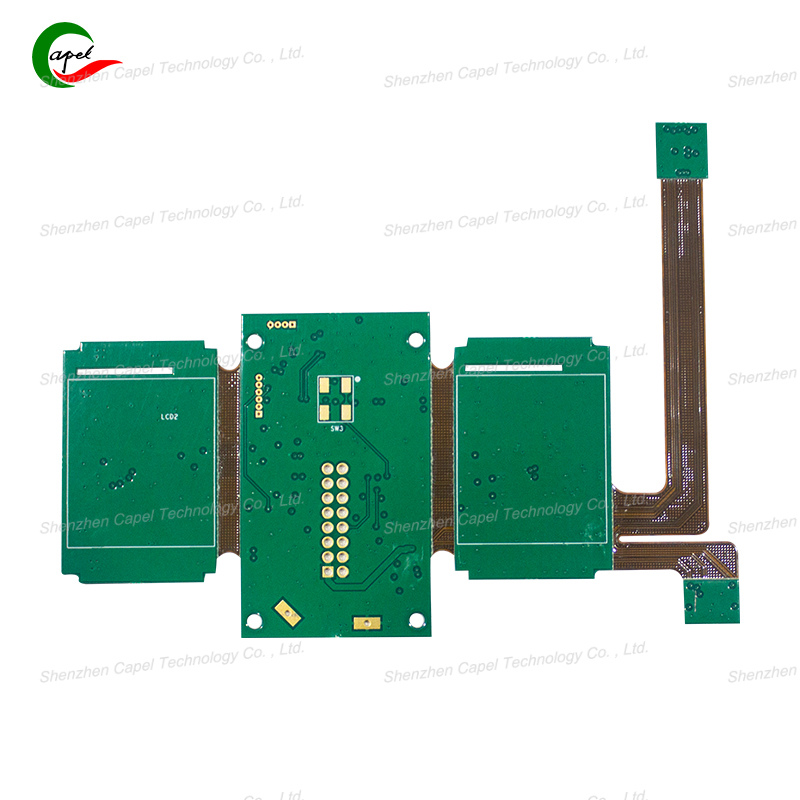

If you’ve ever struggled to fit rigid PCBs into bendable devices, or grown frustrated with messy wires connecting separate rigid and flexible boards—you know how much PCB limitations can slow down your project. At Kaboer, we’ve spent 16 years specializing in rigid-flex PCB development, specifically to solve these pain points: a single board that bends where you need it, stays strong where you don’t, and easily fits into the tightest spaces.

Unlike generic rigid-flex PCBs that force you to compromise on design, Kaboer’s products are fully tailored to your device. Whether you’re developing a foldable phone, a wearable medical monitor, or a drone gimbal—we transform your unique needs into a PCB that works well, lasts long, and saves you time and money. Below is why Kaboer is worth your trust.

Generic rigid-flex PCBs have fixed bend angles and rigid sections, but your device is far from "generic." At Kaboer, we always start with your requirements:

-

Custom Bend Points & Angles: Whether you need a 180° fold for a flip phone hinge or a gentle curve for a wrist-worn wearable, we map every bend using 3D models to ensure perfect alignment with your device’s shape.

-

Customized Material Combination: High-grade polyimide is used for flexible sections (withstands 15,000+ bends without cracking), while IPC-certified FR-4 substrate is used for rigid sections (stably supports heavy components like batteries and microchips).

-

Precise Component Placement: Components are concentrated in rigid sections for stability, and flexible areas are left with ample space for movement—preventing component damage during bending.

Kaboer’s rigid-flex PCBs are not just a better design choice—they’re a smart financial decision:

-

Fewer Parts, Simpler Assembly: One Kaboer rigid-flex PCB replaces 2-3 separate boards (and the wires connecting them), significantly reducing assembly steps and part counts.

-

Lower Failure Risk: Wires and connectors are the top causes of PCB failures. Our rigid-flex PCBs eliminate these weak points, reducing maintenance costs at the source.

-

Avoid High Remodeling Costs: If you need to adjust your device (e.g., modify a bend angle), we only optimize the flexible section—no need to redesign the entire PCB, saving time and R&D expenses.

Manufacturing rigid-flex PCBs is far more complex than standard PCBs. Lack of experience often leads to wire breakage, insufficient bend strength, or misaligned components. Kaboer’s 16 years of industry experience help you avoid these risks:

-

Free Design Review: Before production, our engineers thoroughly review your design to identify potential issues such as "excessively tight bend here" or "this component should be placed in a rigid section." We once helped a medical device brand avoid a major mistake—they almost placed a heavy chip in a flexible section.

-

Targeted Testing & Validation: Every Kaboer rigid-flex PCB undergoes three key tests:

-

Bend Test (15,000+ cycles to simulate real-world use);

-

Temperature Test (-40°C to 125°C, suitable for harsh environments like outdoors and industrial settings);

-

Electrical Test (ensures no signal loss in flexible sections for stable device operation).

We also provide you with a detailed test report, so you can confirm reliability before receiving the product.

-

Dedicated Support Team: A dedicated contact person is assigned to your project, with full knowledge of your requirements. No need to repeat details to different teams—our team responds to inquiries within 8 hours, even handling urgent issues on weekends.

We understand the importance of project timelines, so we’ve optimized the entire production process to ensure fast delivery of rigid-flex PCBs:

-

Prototypes: Delivered in 5-7 days; 48-hour expedited service is available for trade shows or urgent adjustments.

-

Mass Production: Delivered in 10-14 days; key materials are stocked in advance, eliminating waiting time for suppliers and shortening production cycles.

-

Transparent Tracking: Once the product ships, a logistics tracking link is sent to you immediately—you can check the order status anytime, no guesswork needed.

At Kaboer, we don’t just sell rigid-flex PCBs—we work with you to bring your device to life. Whether you’re a startup developing a breakthrough wearable or a Fortune 500 brand launching a foldable flagship product, we support your project with 16 years of expertise, customized solutions, and quality guarantees.

Ready to stop letting PCBs limit your design? Contact us today for a free design review and quote. Turn your "impossible" design into a standout product—choose Kaboer rigid-flex PCBs and start your efficient R&D journey.

Related Link: