Date: 2026-01-17

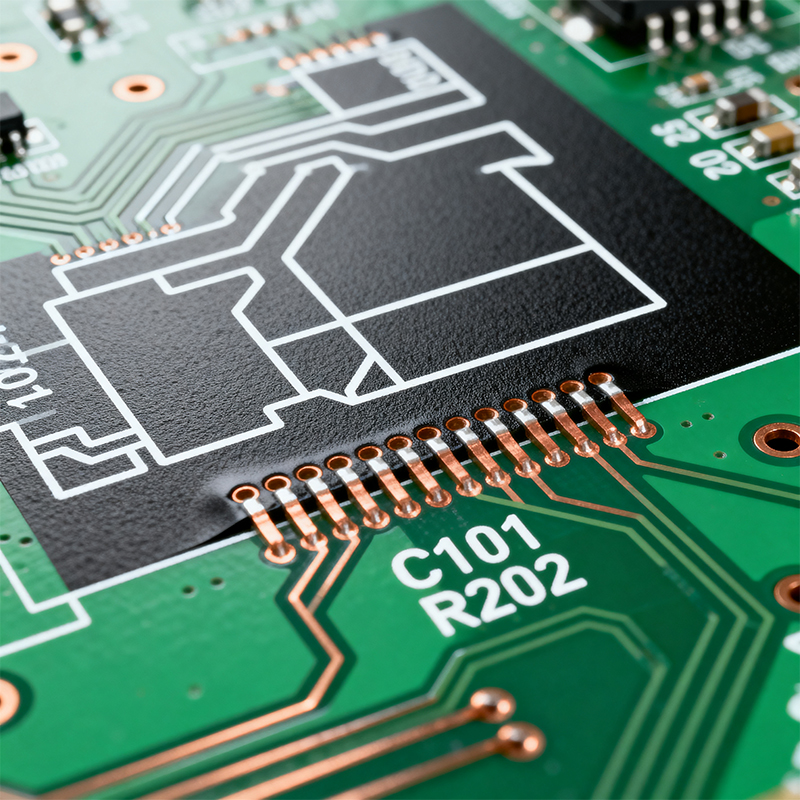

You may never have paid much attention to those small white letters and symbols on circuit boards—until the day your assembly worker holds up a board and asks, "Which way does this diode go?" Or a repair technician complains, "I can't find the test points anywhere." These seemingly insignificant white markings are the PCB silkscreen, and they play a much more important role in electronics manufacturing and use than you might think.

Simply put, PCB silkscreen is the text, numbers, and symbols printed on the surface of a circuit board. It usually appears white but can also be yellow, black, or other colors. Think of it as the circuit board's "instruction manual"—telling people what's on the board and how to use it.

Imagine if there were no silkscreen:

Assembly workers wouldn't know where components go

Repair technicians couldn't find points to test

You couldn't even tell which product version the board is for

That's why even the simplest circuit boards almost always have a silkscreen layer.

This is the silkscreen's most basic and crucial function:

Reference designators: Like R1 (first resistor), C5 (fifth capacitor), U3 (third integrated circuit). It's like giving each component a name tag.

Polarity markings: For components with positive and negative ends, the silkscreen clearly indicates which is which. A line next to a diode, a "+" next to an electrolytic capacitor—these are common polarity markers.

Orientation indicators: Some components must be installed in a specific direction. The small dot or notch on an IC chip, arrows next to connectors—all show the correct installation orientation.

Product model and name

Version or revision codes (especially when designs have been modified)

Manufacturer information

Production date or lot numbers

Test point labels (like "TP1," "GND test point")

Jumper setting instructions (like "JP1: 1-2 normal, 2-3 test")

Interface identification (like "Power input," "USB port")

Safety warnings (like high-voltage area alerts)

Like printing T-shirts, this is the most common and economical method:

Create a screen with the pattern (areas to be printed are open)

Align the screen to the circuit board

Squeeze ink across the screen; ink passes through open areas onto the board

Heat-cure the ink

This method works for most applications but may not be clear enough for very small text or complex patterns.

This method is more precise, similar to how solder mask is made:

Coat the entire board with photosensitive ink

Expose to UV light to cure areas where silkscreen should remain

Wash away uncured ink

Heat-cure

This method produces finer patterns with higher resolution but at higher cost.

The newest technology, similar to an office printer:

No screens needed; prints directly from computer files

Particularly good for small batches and quick prototypes

Easily prints variable information (like unique serial numbers for each board)

Size matters

Characters too small may blur together after printing; too large wastes space. Typically recommended:

Minimum character height: 1.0mm or more

Minimum line width: 0.15mm or more

Color contrast must be strong

White silkscreen shows up best on green solder mask because of the strong contrast. But if your board has black solder mask, white silkscreen still works, though yellow might be clearer. White solder mask needs black silkscreen.

Avoid printing where it shouldn't go

Silkscreen must never be printed on:

Pads (affects soldering)

Gold fingers or contact areas

Areas requiring heat dissipation

Places that will be completely covered by large components

Close but not touching

Component identifiers should be near their corresponding components but with enough distance to ensure:

They won't be covered by the component itself

They remain visible after assembly

They're easy to find during repair

Consistent orientation

All text should preferably face the same direction (horizontal or vertical), avoiding situations where workers need to constantly rotate the board to read.

Highlight critical information

Polarity marks, orientation indicators, test points—these critical pieces of information can be emphasized with larger size or special symbols.

Usually caused by:

Characters designed too small

Ink too thin or too thick

Incorrect printing parameters

Solution: Adjust designs to match manufacturer's capabilities; work with manufacturer to optimize printing parameters.

Possible causes:

Silkscreen layer not properly aligned with other layers in design files

Registration errors during printing

Board warpage during processing

Solution: Ensure precise layer alignment during design; choose manufacturers with strong process capabilities.

White silkscreen in particular may yellow after reflow soldering heat. If this affects readability:

Consider using high-temperature specialized inks

Switch to other silkscreen colors

Avoid placing important information near heat-dissipating components

When boards are densely packed with components, there may not be enough space for complete silkscreen. In such cases:

Label only the most critical information (polarity, orientation)

Use abbreviations or codes

Move some information to less crowded board areas

Flexible board surfaces may be uneven, presenting greater challenges:

Special inks may be needed for proper adhesion

Character designs should be simpler

Consider laser marking as an alternative

If products are sold in different countries, sometimes multi-language labeling is needed:

Ensure sufficient space

Consider using internationally understood symbols instead of words

Or produce different versions for different markets

As components keep shrinking, silkscreen characters need to shrink too. This demands more from manufacturing processes.

Silkscreen needs to be readable by machines as well as people:

QR codes storing more information

Special markings helping Automated Optical Inspection systems with positioning

Machine-readable characters and symbols

Environmental requirements are pushing inks toward halogen-free, low-VOC formulations.

Think one step ahead during design: Imagine how assembly workers, test engineers, and repair technicians will use the silkscreen information.

Communicate with manufacturers early: Understand their process capabilities—know what's possible and what's difficult.

Verify with physical samples: After receiving the first boards, check silkscreen clarity and usefulness in actual working conditions.

Continuously optimize: Keep improving silkscreen designs based on real-world feedback.

PCB silkscreen is far more than decoration—it's a crucial communication bridge between the circuit board and its users. Good silkscreen design significantly improves production efficiency, reduces errors, and facilitates repairs; poor silkscreen can cause ongoing problems.

Investing time in designing clear, practical silkscreen pays continuous returns throughout a product's lifecycle. After all, when people can easily understand a circuit board, all related work becomes smoother and more efficient.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..