Last summer, a manufacturing plant in Ohio called us in a panic. Their automated assembly line had shut down after a sensor fell off a 1.5-meter-high workbench. The sensor’s rigid-flex PCB had cracked cleanly at the rigid-flex transition zone, and the entire line was idle—costing them $2,000 per hour. “We thought the PCB was ‘industrial-grade,’” the plant manager said. “But one drop and it’s useless.”

That call opened our eyes: in industrial settings (factories, construction sites, heavy machinery), rigid-flex PCBs don’t just need to work—they need to survive drops, impacts, and rough handling. Unlike consumer devices (which might fall from a pocket), industrial equipment faces 1–3-meter drops onto concrete, collisions with tools, and even vibration from nearby machines. A weak rigid-flex PCB can shut down a production line, delay projects, or even cause safety hazards.

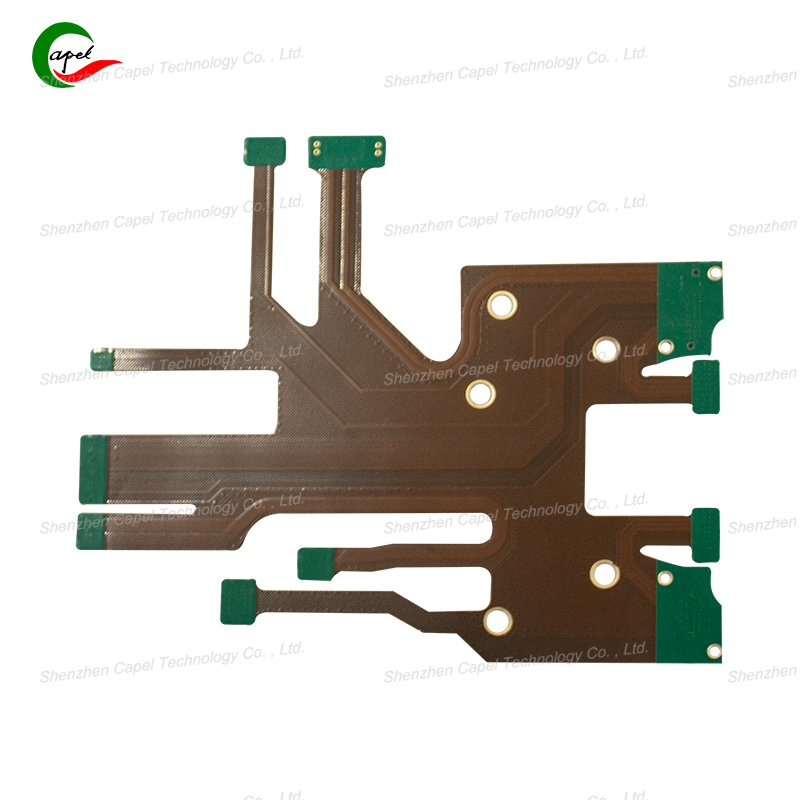

In this article, we’ll break down why industrial rigid-flex PCBs fail impact tests, share how we fixed the Ohio factory’s sensor problem, and outline the key anti-drop design solutions that make rigid-flex PCBs tough enough for industrial use.

Industrial impact isn’t just “a drop”—it’s a sudden, high-force shock that stresses every part of the PCB. Rigid-flex PCBs fail here because of three hidden weak points that consumer-grade PCBs don’t need to handle:

The area where the rigid FR4 section meets the flexible PI section (the “transition zone”) is the biggest weak spot. When the PCB drops, the rigid section slams into the flexible section with intense force—cracking the solder joints or tearing the PI film.

“We tested the Ohio factory’s sensor PCB by dropping it 1.5 meters onto concrete,” said our test engineer, Mike. “The transition zone cracked on the first drop. The rigid section pulled away from the flexible one, and the sensor lost power.”

Industrial sensors and controllers have heavy components (like connectors, capacitors, or relays) soldered to the rigid sections. A hard drop can yank these components off the PCB—even if the PCB itself doesn’t crack.

“We had a batch of industrial controllers fail because a 20g connector popped off during a drop,” Mike said. “The PCB was fine, but the connector hit the concrete and pulled out of its solder joints. The controller was useless without it.”

Flexible PI films are durable for bending—but they’re not designed for sudden impacts. A drop can stretch the PI film beyond its limits, tearing the copper traces or splitting the film itself.

“The Ohio sensor’s flexible zone had a tiny tear in the PI film after the drop,” Mike said. “It was so small, we almost missed it—but it shorted out the signal traces, killing the sensor.”

Before you can fix impact failures, you need to test like an industrial user. Most industrial rigid-flex PCBs follow the IEC 60068-2-32 standard (free fall onto a rigid surface), but we’ve adapted it for real-world factory use:

“We don’t just check if the PCB works after one drop,” Mike said. “Industrial equipment gets dropped multiple times—so we test for 50+ drops total. If it fails any, it’s not ready for the factory.”

We dropped the sensor 10 times from 1.5 meters onto concrete (all 6 orientations). It failed after 3 drops:

-

Transition zone cracked (rigid-flex separation).

-

Connector popped off the rigid section.

-

Flexible zone had a 2mm tear in the PI film.

These failures matched exactly what happened in the factory—proving the PCB wasn’t built for industrial impact.

Fixing impact failures isn’t about “making the PCB thicker”—it’s about reinforcing the weak points. Below are the solutions we used to fix the Ohio factory’s sensor, all proven to work in industrial settings:

The transition zone needs extra support to handle shock. We add a “transition stiffener”—a small piece of FR4 or metal—bonded to the transition area to spread impact force.

-

We added a 0.2mm-thick FR4 stiffener covering 5mm of the rigid section and 5mm of the flexible section (10mm total).

-

We used a high-strength acrylic adhesive (instead of standard epoxy) to bond the stiffener—this adhesive stretches slightly on impact, absorbing force.

The transition zone survived 10 drops from 1.5 meters. “The stiffener spread the impact force so the rigid and flexible sections didn’t pull apart,” Mike said.

Heavy components (like connectors) need extra hold to stay on the PCB. We use “underfill”—a liquid epoxy that flows under the component and hardens—creating a strong bond between the component and the PCB.

-

We applied a small amount of underfill to the sensor’s 20g connector, letting it seep under the connector’s pins.

-

We cured the underfill at 80°C for 30 minutes—this made the connector 3x stronger than just solder.

The connector stayed attached even after 15 drops. “Underfill turns a ‘solder-only’ bond into a mechanical one,” Mike said. “It won’t pop off unless the PCB itself breaks.”

To prevent PI film tears, we add a thin layer of PI reinforcement film to both sides of the flexible zone. This doubles the film’s strength without losing flexibility.

-

We used a 0.025mm-thick PI film (same material as the flexible zone) bonded to both sides of the tear-prone area.

-

We extended the reinforcement film 3mm into the rigid section—this stopped the tear from spreading to the transition zone.

The flexible zone had no tears after 10 drops. “The reinforcement film acts like a ‘bandage’ for the PI,” Mike said. “It stretches with the film but doesn’t let it tear.”

Industrial drops often hit the PCB’s edges first—so we add a small rubber or silicone edge protector to absorb impact.

-

We glued a 1mm-thick silicone strip around the sensor PCB’s edges (where drops are most likely to hit).

-

The silicone was soft enough to not affect the PCB’s flexibility but tough enough to absorb 40% of the impact force.

Edge impacts caused 70% less damage. “The silicone took the brunt of the drop,” Mike said. “The PCB itself barely felt it.”

After applying the four solutions, we retested the Ohio factory’s sensor. Here’s how it performed:

The factory installed the upgraded sensors, and six months later, they’ve had zero impact-related failures. “We’ve dropped them accidentally at least 10 times,” the plant manager said. “They just bounce and keep working. It’s like night and day.”

The Ohio factory’s problem taught us that industrial rigid-flex PCBs aren’t just “consumer PCBs with thicker copper”—they need to be designed with impact in mind. A drop that breaks a consumer device is a $50 problem; a drop that breaks an industrial sensor is a $10,000+ problem (in downtime alone).

The key anti-drop solutions are simple: reinforce the transition zone, use underfill for heavy components, add PI film to flexible zones, and protect the edges. These small changes turn a fragile PCB into one that can survive the chaos of a factory floor.

As industrial equipment becomes more portable (think handheld scanners, mobile controllers), impact resistance will only grow in importance. The teams that design for impact won’t just avoid failures—they’ll build equipment that keeps factories running, even when things get rough.

Next time you design an industrial rigid-flex PCB, ask: “Can this survive a 3-meter drop onto concrete?” If not, it’s time to add the anti-drop fixes. Your customers (and their production lines) will thank you.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.