Date: 2026-01-27

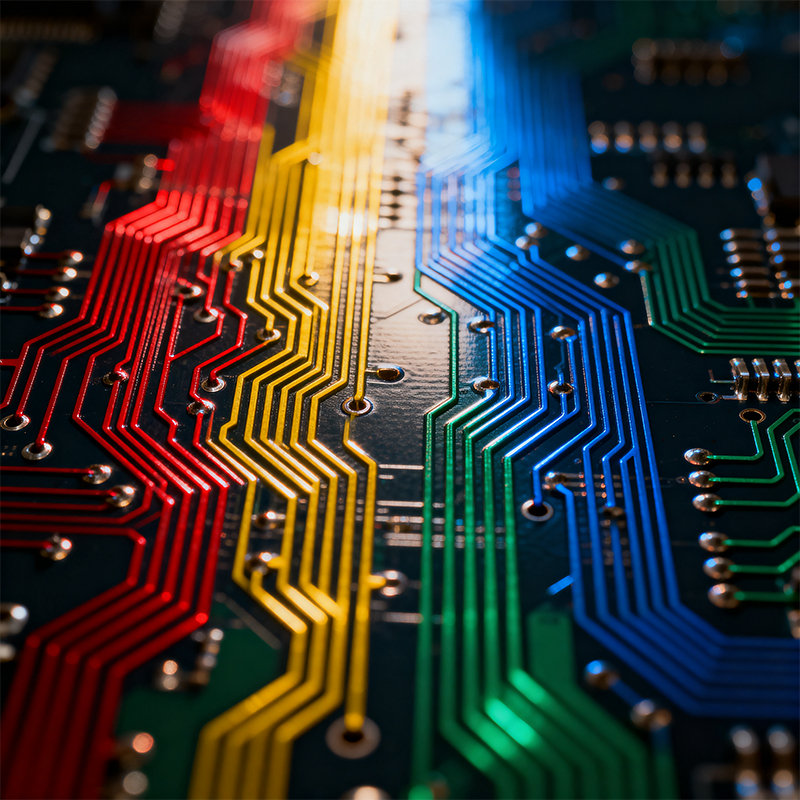

You’ve probably noticed that circuit boards come in different colors. Most are green, but you’ll also see blue, red, black, and even white or purple ones. Is this just about looks, or does the color actually matter for electronics manufacturers? Let’s talk about what’s really going on with that colored coating.

It’s All About the “Solder Mask”

First, the color you see isn’t the color of the fiberglass board itself. It’s the color of a protective coating called the solder mask or solder resist. Think of it like the colored nail polish on top of your nails. Its main job is to protect the copper traces from corrosion, prevent solder bridges during assembly, and provide electrical insulation.

Why Green is the Classic Choice

Ever wonder why green is the default? It turns out it’s mostly about history and practicality.

Historical Legacy: Early solder mask materials (called LPI) were naturally greenish, and the industry just stuck with it.

Eye Comfort for Inspectors: Green provides a high contrast against the shiny silver solder joints and the copper traces, making it easier for human inspectors and automated optical machines to spot defects during manufacturing.

Reliability: The green pigment formula has been perfected over decades, making it very reliable in the curing process.

What Other Colors Mean

Different colors have become popular for various reasons:

Blue: Often used in development boards or for a “cleaner” aesthetic look. Offers good contrast as well.

Red: Provides high contrast for both humans and cameras; sometimes chosen for visibility or branding.

Black: Looks sleek and premium (common in high-end consumer electronics). However, it can make visual inspection of traces slightly harder due to lower contrast and might absorb more heat during soldering.

White: Essential for LED boards, as it reflects light. Can show dirt and scratches more easily.

Yellow/Purple: Less common, usually chosen for specific visibility needs or unique product identities.

Practical Considerations for Manufacturers

Inspection & Repair: Green and blue are generally easiest for technicians to debug and rework on. Darker colors like black can hide fine traces under normal light.

Thermal Properties: Different pigments can slightly affect how heat is absorbed and dissipated during the soldering reflow process. Most modern formulations account for this, but it's good to confirm with your fabricator.

Cost & Availability: Green is almost always the standard and most affordable. Other colors might have a small premium or longer lead time. White can be particularly tricky to get perfectly even.

Silkscreen Visibility: The white legend (text and symbols) printed on top needs to stand out. Black PCB with white silkscreen has high contrast, but yellow on green is the classic, highly readable combo.

The Bottom Line

Choosing a PCB color is rarely just about aesthetics. It’s a practical decision that can affect:

Manufacturing ease and inspection accuracy

Debugging and repair efficiency

Final product look and feel

For most industrial and functional applications, green remains the no-nonsense, reliable workhorse. When you choose another color, it’s good to know the subtle trade-offs involved.

Next time you see a blue development board or a black gaming motherboard, you’ll know there’s a bit more to that color choice than meets the eye.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..