High-frequency signals (think 1GHz and above) are the lifeblood of modern gadgets—powering everything from 5G phones to medical scanners. But these signals are finicky: when they travel through a rigid-flex PCB, "impedance" (a kind of electrical "resistance" for AC signals) can disrupt them, causing delays, glitches, or even signal loss.

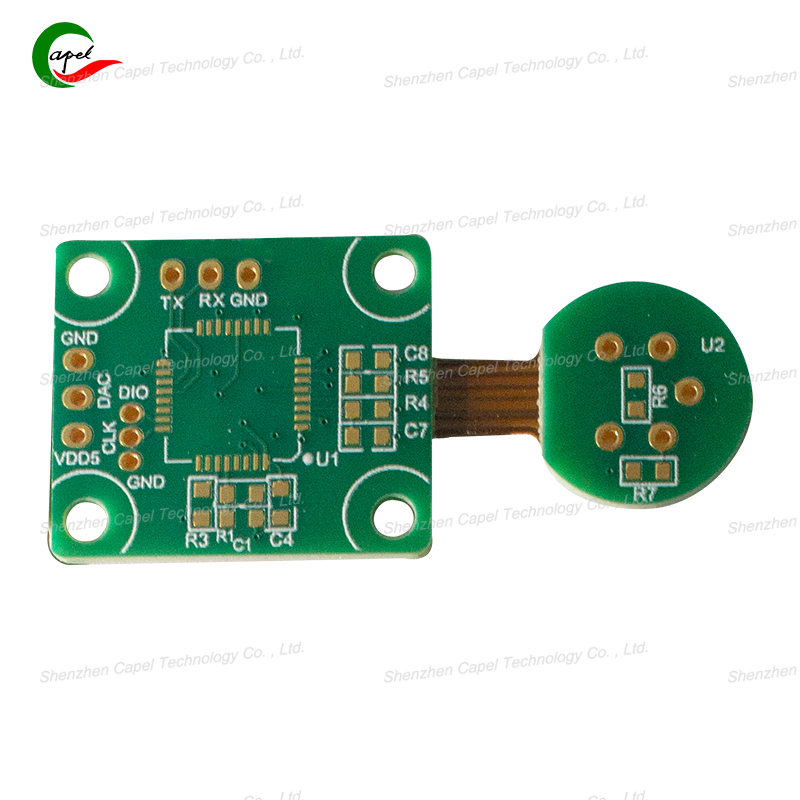

For rigid-flex PCBs—with their mix of rigid FR-4 and flexible PI layers—controlling impedance is trickier than for standard PCBs. But it’s not impossible. Below’s a simple breakdown of what impedance is, why it matters for high-frequency signals, and how to keep it stable in rigid-flex designs.

Think of a high-frequency signal as water flowing through a hose. If the hose suddenly narrows or widens, the water flow gets turbulent. Impedance is like the "width" of the electrical "hose" for signals.

When impedance changes along the PCB (e.g., where flexible PI meets rigid FR-4), the signal gets "turbulent"—it reflects back instead of moving forward. This causes:

-

Signal distortion: Data (like a 5G video stream) gets blurry or corrupted.

-

Delay: Signals take longer to reach their destination.

-

Energy waste: Reflected signals sap power from the circuit.

For rigid-flex PCBs, the biggest impedance risk is the transition between rigid and flexible layers—two materials with different electrical properties.

The key to stable high-frequency signals is making sure impedance stays the same (called "impedance matching") everywhere the signal travels. Here’s how to do it:

-

Choose consistent materials

Rigid FR-4 and flexible PI have different "dielectric constants" (a number that affects impedance). Pick low-dielectric materials for both:

-

Flexible layer: PI with a dielectric constant of 3.0–3.5 (avoid cheap PI with higher values).

-

Rigid layer: FR-4 with a dielectric constant of 4.2–4.5 (standard for high-frequency use).

This minimizes impedance jumps between layers.

-

Keep trace width & spacing uniform

Impedance depends heavily on how wide your copper traces are and how far they are from ground planes. If a trace is 0.2mm wide on the flexible layer but 0.3mm on the rigid layer, impedance will spike. Use the same trace width (e.g., 0.2mm) and spacing from ground (e.g., 0.3mm) across all layers.

-

Design a continuous ground plane

A ground plane (a large copper layer) acts as a "reference" for signals, stabilizing impedance. Make sure the ground plane extends seamlessly from the rigid layer to the flexible layer—no gaps at the rigid-flex transition. This gives signals a consistent "reference point" everywhere.

The spot where FR-4 meets PI is where impedance often goes wrong. Fix it with these tweaks:

-

Extend the flexible coverlay

The flexible layer’s protective coverlay (PI film) should overlap the rigid layer by 2–3mm. This smooths the transition between materials, preventing sudden impedance changes.

-

Avoid vias near the transition

Vias (holes that connect layers) disrupt impedance. Keep them at least 5mm away from the rigid-flex boundary—this gives signals time to stabilize before crossing layers.

-

Use a "tapered" trace transition

If you must change trace width (e.g., for a connector), taper it gradually (over 3–4mm) instead of making a sharp jump. A slow taper keeps impedance from spiking.

Stable impedance isn’t just a "technical box to check"—it directly affects how your device works:

-

Reliable high-speed data: 5G, Wi-Fi 6, and video streaming need consistent signals—impedance matching keeps them smooth.

-

Less noise: Reflected signals cause electrical noise, which can ruin sensitive data (like medical scan results).

-

Longer signal range: Stable signals travel farther without losing strength—critical for devices like wireless routers.

Controlling impedance in rigid-flex PCBs boils down to one idea: keep the "electrical hose" for signals consistent—same width, same materials, same reference ground. The hardest part is the rigid-flex transition, but with overlapping coverlays and uniform traces, you can fix that.

High-frequency signals are delicate, but they don’t have to be unpredictable. By focusing on impedance matching, you can make a rigid-flex PCB that carries fast signals without glitches—proving that even complex electrical problems have simple, practical solutions.

Related Link: