Smart Ring FPC: Wiring Tips for Tiny Spaces

Date: 2025-09-16

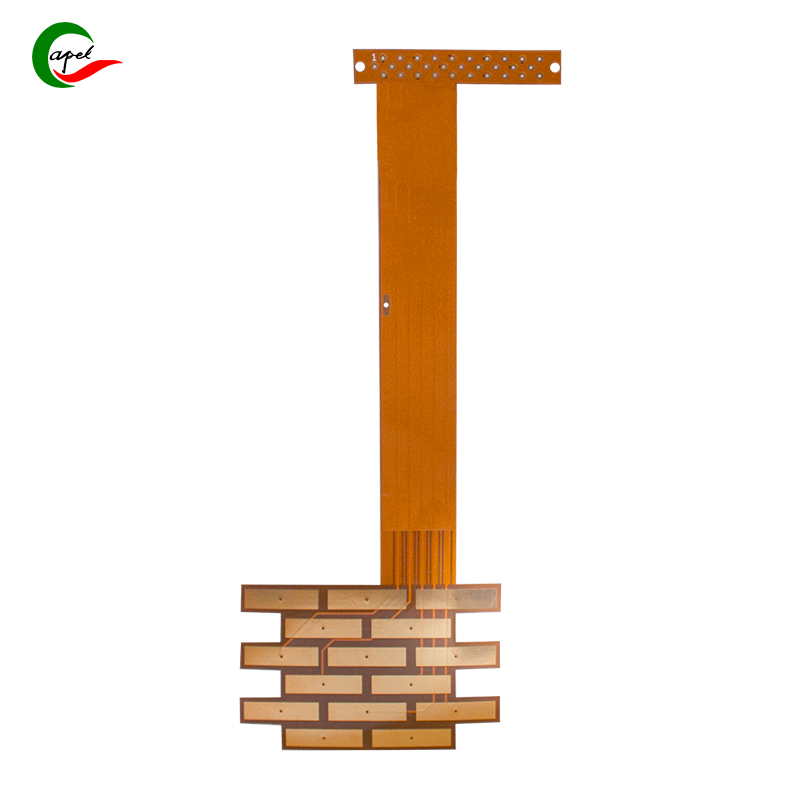

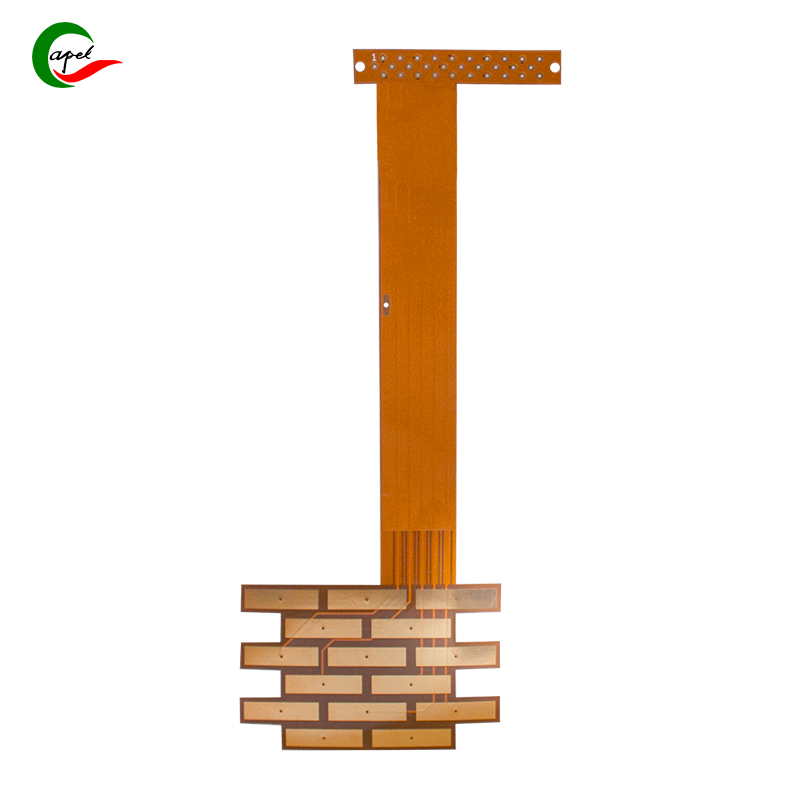

A smart ring is one of the most space-constrained gadgets out there—its inner diameter is often just 15–20mm, with barely 1–2mm of room for electronics. The flexible PCB (FPC) inside has to do the impossible: connect sensors (for heart rate or temperature), a tiny battery, a microchip, and a wireless module—all without overlapping, breaking, or making the ring feel bulky.

Wiring an FPC for a smart ring isn’t about squeezing more parts in—it’s about smart layout. Below’s a simple breakdown of the key tricks to route circuits in minimal space, and why these choices matter for how the ring works and feels.

Ordinary FPCs work for larger gadgets (like earbuds), but smart rings have unique challenges:

-

Extreme space limits: Every millimeter counts. A single misrouted trace can force you to make the ring thicker (ruining comfort) or cut a sensor.

-

Flexibility + durability: The FPC has to bend slightly when the ring is put on/taken off, but can’t crack after repeated use.

-

Signal crowding: Sensors, battery, and wireless modules all send signals—pack them too close, and they interfere (e.g., heart rate data gets messy).

These tricks turn tight spaces into usable real estate for your FPC:

-

Use ultra-thin, single-layer FPC (when possible)

Most smart rings only need 1 layer of copper traces—2 layers add thickness you don’t have. Opt for 0.01mm thin copper foil and 0.025mm polyimide (PI) base; this keeps the FPC as thin as a sheet of paper, so it fits under the ring’s outer casing.

-

Route traces along the ring’s curve (not across it)

Run traces parallel to the ring’s inner circumference, like lines around a pipe. This avoids sharp bends (which weaken the FPC) and uses the ring’s full length instead of wasting space on crosswise 布线.

-

Stack components “vertically” (not side-by-side)

Instead of placing the battery next to the sensor (which takes width), mount low-profile components (like a 0.5mm-thick battery) directly on top of the FPC. Use “through-hole vias” (tiny holes) to connect top-side components to bottom-side traces—no extra space needed.

Small errors here cost big in a smart ring. Watch for these pitfalls:

-

Don’t leave gaps between components: Place parts (sensor, chip, module) as close as possible—1mm apart max. Use “chip-on-flex” (COF) technology to mount the microchip directly on the FPC (no bulky socket needed).

-

Skip unnecessary traces: Merge power traces (for battery) where possible—one thick trace can power multiple low-energy components (like a sensor and LED) instead of two thin ones.

-

Avoid wide traces (unless you have to): Most smart ring circuits use low power, so 0.1mm-wide traces work (half the width of standard FPC traces). Only use 0.3mm traces for the battery (it needs more current).

Good FPC wiring doesn’t just fit parts—it makes the ring better to wear and use:

-

Thinner, lighter ring: A well-routed FPC lets the ring stay under 2mm thick—thick rings feel clunky and slip off.

-

More reliable data: No signal interference means heart rate or sleep tracking is accurate.

-

Longer battery life: Efficient wiring uses less power, so the ring charges less often.

Wiring an FPC for a smart ring is a game of “less is more”—thinner materials, smarter routing, and no wasted space. It’s not about cramming components; it’s about designing the FPC to fit the ring, not the other way around.

The next time you look at a smart ring, remember: the tiny FPC inside is a lesson in precision. Every trace has a purpose, every component has a spot, and every millimeter is used wisely. That’s how you turn a “too-small” space into a functional, comfortable smart gadget.

Related Link: