In the precision-driven world of rigid-flex PCBs—where reliability is non-negotiable for aerospace, medical, and automotive electronics—one defect stands out as a silent killer: exposed "fake copper." This isn’t actual copper but a thin, brittle layer of oxidized or poorly bonded copper that appears intact during inspection but fails under real-world stress. Left unaddressed, it leads to corrosion, signal loss, or even catastrophic failures—think a pacemaker malfunction or a drone losing navigation mid-flight.

Avoiding exposed fake copper requires a mix of material science, process control, and quality checks. Here’s how to eliminate this costly defect from your rigid-flex manufacturing workflow.

What Is "Fake Copper" and Why It’s Dangerous

"Fake copper" refers to copper layers that look structurally sound but lack the integrity to perform over time. It manifests in two common forms:

- Oxidized copper: A thin layer of copper oxide (CuO or Cu₂O) forms on the surface due to poor storage or processing, creating a brittle barrier that resists soldering and conducts poorly.

- Poorly bonded copper: In rigid-flex PCBs, where flexible polyimide (PI) layers meet rigid FR4, copper may delaminate slightly at the interface, leaving a weak, "hollow" layer that cracks under bending or thermal stress.

The danger lies in its invisibility: Fake copper passes visual inspections but fails under mechanical stress (e.g., flexing) or environmental exposure (moisture, heat). In critical applications like automotive ADAS sensors, this can trigger false readings or system shutdowns.

Root Causes: Why Fake Copper Appears in Rigid-Flex PCBs

Rigid-flex boards are uniquely vulnerable to fake copper due to their hybrid construction—combining rigid FR4, flexible PI, and multiple copper layers. Key culprits include:

1. Inadequate Surface Preparation

Before lamination, copper surfaces must be free of oxidation, oils, or contaminants. Even a thin film of grease or oxide prevents proper adhesion:

- Oxidation during storage: Copper foils left exposed to air (especially in humid environments) form a passive oxide layer within 24–48 hours.

- Residue from cleaning: Using low-quality solvents or insufficient brushing leaves behind contaminants that weaken bonding.

2. Mismatched Lamination Parameters

Rigid-flex lamination involves bonding dissimilar materials (FR4 and PI) with copper in between. Missteps here create weak spots:

- Temperature inconsistencies: PI requires higher lamination temperatures (356°F/180°C) than FR4 (320°F/160°C). Uneven heating causes copper to bond poorly to one material while overheating the other.

- Pressure gaps: Air bubbles trapped between layers during lamination create voids where copper isn’t fully bonded—these voids expand under thermal stress, exposing fake copper.

3. Poor Etching Control

Over-etching or under-etching during circuit patterning thins copper unevenly:

- Over-etching: Removes too much copper from corners or tight bends (common in flexible sections), leaving thin, fragile traces prone to oxidation.

- Under-etching: Leaves residual copper "webs" between traces. These webs are weakly attached and flake off over time, exposing underlying fake copper.

4. Flexure Stress in Flexible Sections

The flexible PI sections of rigid-flex boards bend repeatedly, stressing copper layers:

- Fatigue cracks: Thin copper (9μm–12μm) in flexible areas develops micro-cracks after 10,000+ bends. These cracks trap moisture, accelerating oxidation.

- Adhesive failure: Poorly cured adhesives between PI and copper delaminate under flexing, creating pockets where fake copper forms.

5 Critical Steps to Eliminate Fake Copper

Preventing fake copper requires a proactive approach, addressing issues from material selection to final inspection:

1. Optimize Copper Foil Selection

Not all copper is suited for rigid-flex boards. Prioritize:

- Low-profile rolled annealed (RA) copper: Its smooth surface resists oxidation better than rough electrodeposited (ED) copper. RA copper also withstands flexure without cracking.

- Pre-treated copper: Choose foils with a thin, protective zinc or nickel coating (e.g., "anti-oxidation copper") to slow oxide formation during storage.

2. Rigorous Surface Preparation

Cleanliness is non-negotiable. Implement:

- Abrasive cleaning: Use aluminum oxide brushes (800–1000 grit) to remove oxides and contaminants, followed by high-pressure water rinsing.

- Micro-etching: A light etch (1–2μm removal) with sulfuric acid/hydrogen peroxide creates a micro-rough surface for better adhesion.

- In-line drying: Use hot air knives (180°F/82°C) to dry copper immediately after cleaning—moisture accelerates oxidation.

3. Precision Lamination Controls

Mastering the lamination of FR4 and PI is key:

- Stepwise heating: Ramp up temperature gradually (2°F/1°C per minute) to 356°F/180°C, holding for 60–90 minutes to ensure both FR4 and PI bond properly.

- Uniform pressure: Use vacuum lamination (≤1 torr) to eliminate air bubbles, applying 200–300 psi pressure evenly across the panel.

- Adhesive selection: For rigid-flex interfaces, use high-temperature epoxy adhesives (Tg ≥ 302°F/150°C) that bond equally well to FR4 and PI.

4. Etching Process Optimization

Ensure precise copper removal:

- Etch factor control: Maintain an etch factor (ratio of vertical to lateral etching) of 4:1 to avoid undercutting corners in flexible traces.

- In-situ monitoring: Use optical sensors to measure etch depth in real time, adjusting etchant concentration (typically 1–2% cupric chloride) to prevent over-etching.

- Post-etch cleaning: Neutralize with 5% sulfuric acid, then rinse with deionized water to remove etchant residues that cause corrosion.

5. Robust Inspection and Testing

Catch fake copper before it reaches customers:

- AOI with high-resolution imaging: Use automated optical inspection (5μm pixel size) to detect micro-cracks, voids, or oxidation in copper layers.

- Thermal cycling tests: Expose boards to -40°F to 257°F (-40°C to 125°C) for 500 cycles, then inspect for delamination or copper flaking.

- Bend testing: Flex the PI sections 10,000 times (180° at 0.1-inch radius) and check for resistance changes (should be <5%)—spikes indicate fake copper failure.

Case Study: Eliminating Fake Copper in Aerospace Rigid-Flex

A leading aerospace supplier faced recurring fake copper issues in rigid-flex PCBs for satellite systems, causing 20% of units to fail qualification. By implementing:

- Pre-treated RA copper with zinc coating

- Vacuum lamination with stepwise heating

- Post-etch AOI with 3μm resolution

They reduced fake copper defects to 0.5% and improved field reliability by 99.9%.

Conclusion: Fake Copper Is Preventable

Exposed fake copper in rigid-flex PCBs isn’t an inevitable flaw—it’s a symptom of poor process control. By selecting the right materials, mastering lamination, optimizing etching, and implementing rigorous testing, manufacturers can eliminate this defect.

In industries where failure is not an option, the cost of fake copper extends far beyond rework. It erodes trust, triggers recalls, and risks lives. Investing in prevention isn’t just good manufacturing—it’s the only way to deliver rigid-flex PCBs that perform as promised, every time.

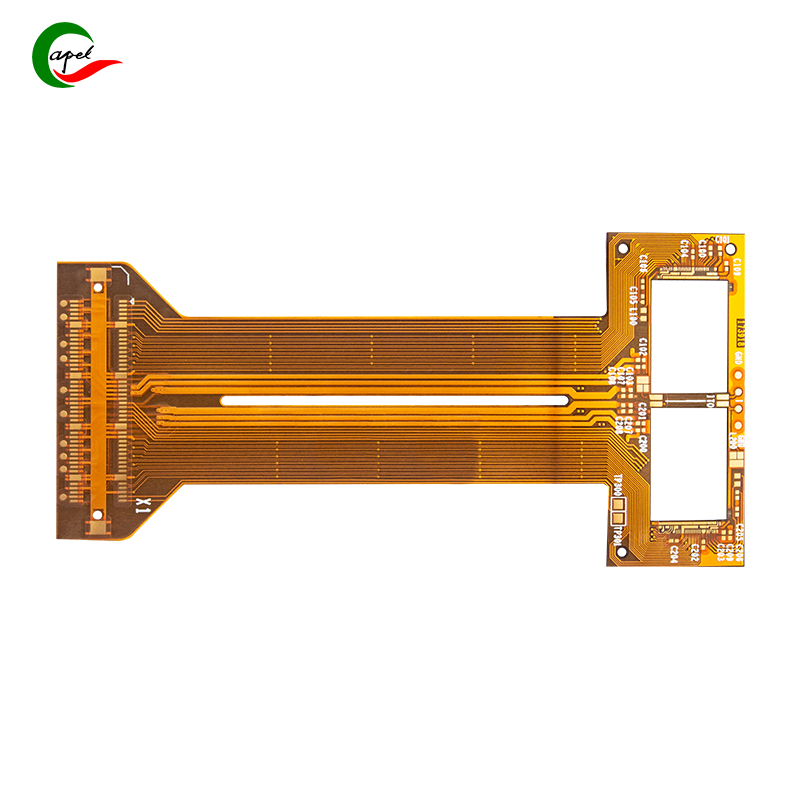

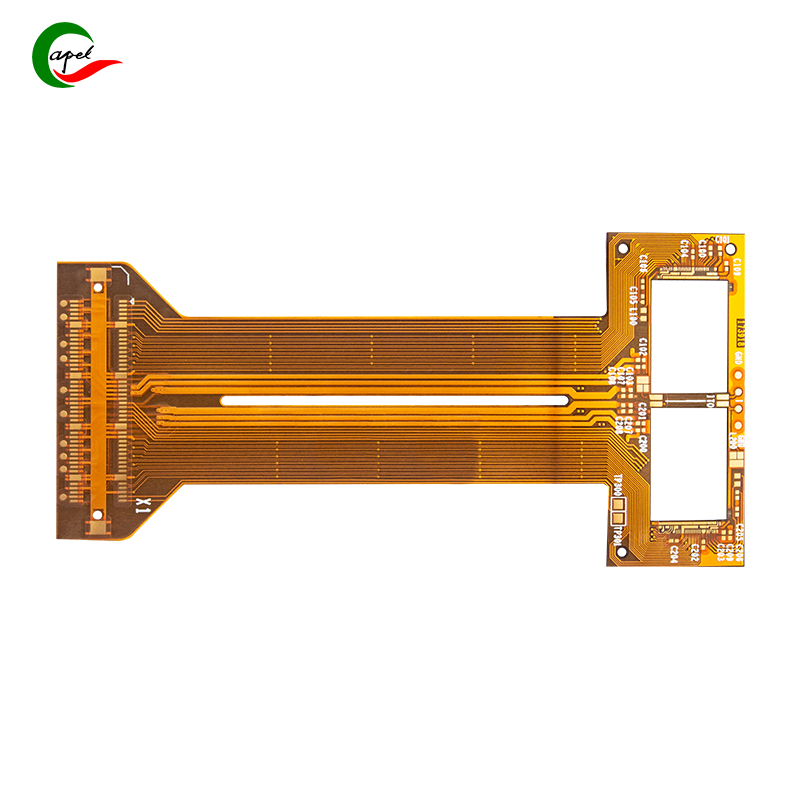

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.