Date: 2025-12-31

Most people think modern electronics are "assembled." A more accurate term is "printed." The key technology behind this is SMT.

Imagine traditional assembly: workers using soldering irons to insert components with long "legs" (leads) into holes on a circuit board and solder them. It's like "threading a needle"—slow, error-prone, and limits miniaturization.

SMT (Surface Mount Technology) changed the game. It makes components flat like "sesame seeds," then uses precision machines to rapidly and accurately "print" these "seeds" onto the surface of a circuit board and solder them securely.

This technology delivers four results you care about:

Smaller, Lighter Products: Components can be over 70% smaller, enabling smartwatches and tiny earbuds.

More Stable and Reliable Performance: Machine soldering is far more consistent than manual work, drastically reducing cold solder joints and misplacements.

Significantly Lower Production Costs: Full automation brings exponential efficiency gains.

Incredibly Fast Production Speeds: A modern SMT line can place tens of thousands to hundreds of thousands of components per hour.

Simply put, SMT is the foundation of modern electronics manufacturing. No matter how brilliant your product design, if the SMT process fails, everything falls apart.

An SMT line is a highly synchronized system. Your circuit board goes through these critical stages, each with its own nuances:

Step 1: Solder Paste Printing — Like Spreading Icing on a Cake

What's happening: Through a laser-cut stencil, a paste mixed with tiny solder balls is precisely "printed" onto the board where soldering is needed.

Where the expertise lies: Paste that's too thick, thin, or misaligned will cause soldering defects. It's like spreading icing—evenness and consistency are crucial for the first step.

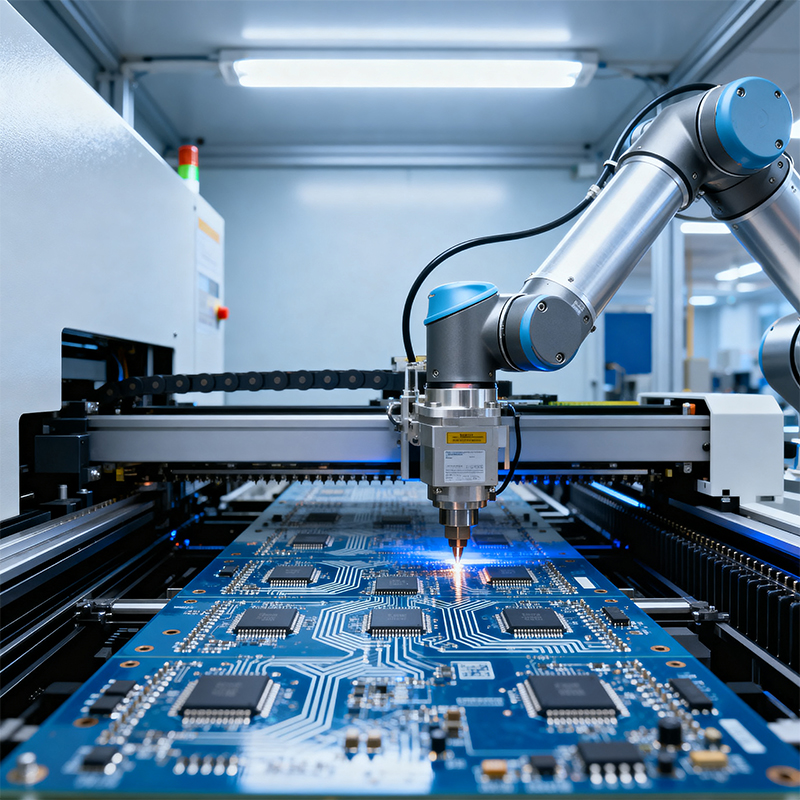

Step 2: Component Placement — Like a High-Speed, Precision "Claw Machine"

What's happening: Nozzles on a pick-and-place machine grab components from reels at lightning speed and, guided by high-def vision systems, place them accurately onto the solder paste.

Where the expertise lies: Precision is measured in microns. Misplacing a tiny 0402 component (1mm x 0.5mm) spells disaster. Machine accuracy, speed, and feeder changeover efficiency directly determine your order turnaround time and yield.

Step 3: Reflow Soldering — Like a Precise "Heat Therapy" Session

What's happening: The board enters a reflow oven, passing through precisely controlled zones (preheat, soak, reflow, cool) to melt and then solidify the solder paste, creating strong solder joints.

Where the expertise lies: The temperature profile is critical. Different components, PCB materials, and pastes require unique profiles. An incorrect profile leads to cold solder joints or heat damage to chips.

Step 4: Eagle-Eyed Inspection — The "CT Scan" at Every Stage

SPI (Solder Paste Inspection): Before placement, a 3D scanner checks the paste's thickness, area, and shape, catching defects at the source.

AOI (Automated Optical Inspection): After soldering, high-res cameras automatically scan for missing, wrong, misaligned, or bridged components.

Where the expertise lies: In top factories, AOI doesn't just "find" problems; it uses data analytics to "predict and prevent" future issues.

Owning SMT machines ≠ mastering SMT technology. The real gap lies in process control capability, which includes:

Mastery of new materials and processes: Handling micro BGA chips, eco-friendly low-temperature solder paste, etc.

Stringent requirements for material consistency: PCB warpage and component coplanarity affect outcomes.

Continuous data analysis and process optimization: Driving yield improvement with data, not just experience.

In Shenzhen, there are thousands of SMT factories. Kaboer's differentiation isn't about owning machines, but about how we operate and optimize them to deliver predictable results for you.

1. We Control the Source: DFM from the "Stencil" Stage

We don't just build to print. Our engineering team reviews your design files upfront, offering Design for Manufacturability (DFM) feedback on component layout, pad design, thermal management, etc. For example, we might suggest moving two components too close together to avoid solder bridging. We help you de-risk at the design stage.

2. We Invest in "Precision," Not Just "Speed"

Our lines are equipped with high-precision, multi-function placers that not only handle high-volume standard parts but also reliably place fine-pitch chips and odd-form connectors. This means consistent accuracy for both simple consumer electronics and complex industrial or medical boards.

3. Our "Oven" is Smart: Full Nitrogen Protection & Precise Thermal Profiling

For boards with high-reliability requirements (e.g., those with many BGA chips), we employ full nitrogen-protected reflow soldering. Nitrogen significantly reduces oxidation during soldering, resulting in shinier, stronger solder joints and vastly improved long-term reliability. We create and validate a unique temperature profile for every new product.

4. We Let Data Talk, Making Quality Visible

Data from our SPI and AOI aren't just isolated reports; they are real-time feedback tools for process control. By monitoring key parameters (like paste volume, component shift) in real-time, the system can alert and auto-adjust at the first sign of a deviation trend, enabling preventive quality control.

5. Rooted in Shenzhen: Supply Chain Agility is Our Native Advantage

Being in the heart of the global electronics supply hub allows us to:

Quickly respond to component substitutions: Rapidly find and validate compliant alternates when a chip is short.

Ensure material freshness: High turnover of paste, adhesives, etc., ensures optimal activity and stable soldering results.

Achieve high collaborative efficiency: Proximity to PCB fabricators, stencil, and fixture shops enables communication and modifications within hours.

Conclusion

For electronics brands, SMT shouldn't be a "black box" you worry about. It should be a transparent, reliable, and trustworthy manufacturing foundation.

Think of Kaboer as your extended manufacturing arm in Shenzhen. We offer not just machines, but manufacturing solutions built on deep process understanding, ensuring your every design intent is accurately and consistently realized into a product.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..