Date: 2026-01-22

Let’s talk about the single most important process that brings an electronic device to life: soldering a circuit board. Without it, your design is just a collection of loose parts and a fancy piece of fiberglass. Soldering is the permanent, conductive glue that makes everything talk to each other.

If you've ever tried to fix a loose wire, you know soldering involves a hot iron and some shiny metal that melts. But in a professional factory, it’s a world of precision chemistry, heat control, and automation. Understanding the basics isn't just for engineers—it helps any manufacturer make smarter decisions about quality, cost, and who to partner with.

At its heart, soldering is using a hot metal "glue" to make a permanent, electrical connection. That "glue" is solder, a special metal alloy (usually tin, silver, and copper) designed to melt at a relatively low temperature (around 200-250°C / 392-482°F) and then harden as it cools.

Think of it like this:

The PCB pad is a clean, flat piece of land.

The component lead or pad is a house that needs to be built on that land.

The solder is the concrete foundation that bonds the house to the land, but this foundation also conducts electricity.

The key is the metallurgical bond. The molten solder doesn't just stick to the surfaces; it dissolves a tiny bit of the copper and component metal, creating a new, strong alloy joint as it cools. A good solder joint is shiny, smooth, and strong. A bad one looks dull, lumpy, and is a failure waiting to happen.

How you solder depends entirely on scale, components, and what you’re trying to achieve.

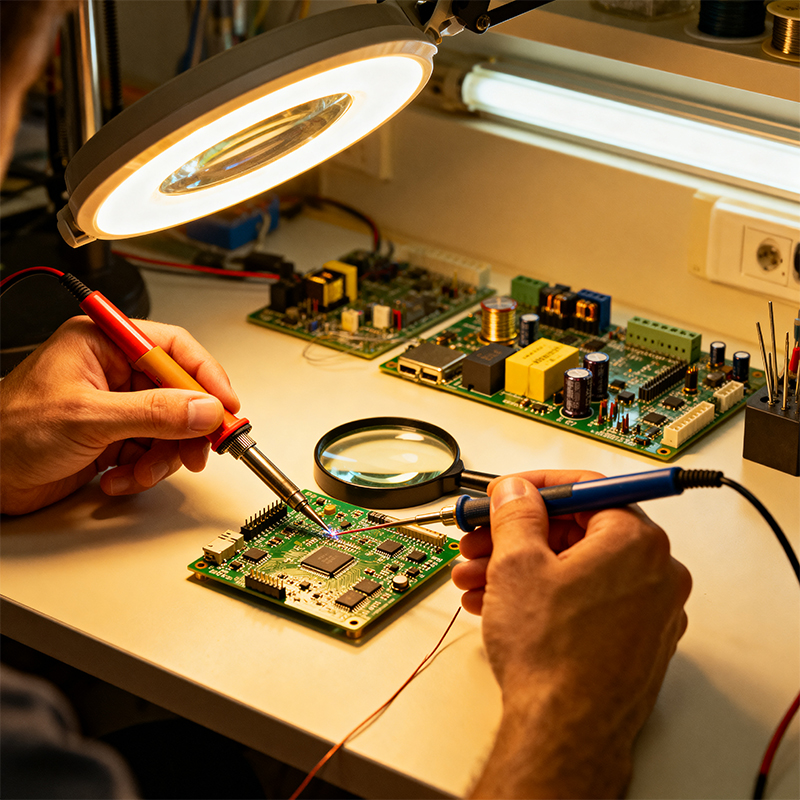

This is what most people picture. A technician uses a temperature-controlled iron to apply solder wire and flux directly to a joint. It's slow and relies on skill.

When it's used: Prototyping, rework, and repair. It's perfect for assembling one-off boards, replacing a single faulty component, or soldering large, odd-shaped parts that machines can't handle.

The Reality: For production, it doesn't scale. Human consistency varies, it's tiring, and you can't hand-solder 10,000 tiny resistors in an hour.

Imagine passing the bottom of a circuit board over a surging, molten wave of solder. That's wave soldering. It's fantastic for boards loaded with through-hole components (the ones with long legs that go through holes).

How it works: The board travels on a conveyor. Flux is applied first to clean the surfaces. Then, the board passes over a laminar wave of molten solder, which wicks up into all the pre-placed through-holes, soldering every pin on the bottom in one go.

Best For: Power supplies, simple control boards, or any design still using a lot of bulky through-hole connectors and components.

This is the absolute king of modern electronics assembly and the core of SMT PCB assembly. It's how your smartphone's motherboard is made.

How it works: It’s a two-step, indirect process:

Solder Paste Application: First, a paste of tiny solder balls and flux is printed onto the board's pads through a stencil.

Component Placement: Robots place all the surface-mount (SMT) components onto the paste.

The Reflow "Oven": The entire board goes through a carefully heated tunnel called a reflow oven. The paste melts (reflows), creating perfect joints under every component, then cools and solidifies. It’s more like baking cookies than dipping them in frosting.

Why it dominates: It’s fully automated, incredibly precise, handles microscopic components, and is the only way to build high-density, multi-layer boards at scale.

Even with great machines, soldering is a dance with physics and chemistry. Common pitfalls include:

Cold Joints: The solder didn't get hot enough to form a proper bond. It looks dull and grainy and will fail electrically and mechanically.

Solder Bridges: Two separate pads get accidentally connected by a blob of solder, creating a short circuit. This is a major risk with fine-pitch chips.

Tombstoning: A tiny chip component (like a resistor) stands up on one end during reflow. This happens when one pad heats up and reflows faster than the other, creating unequal surface tension that pulls the part upright.

Thermal Damage: Applying too much heat for too long can fry sensitive semiconductors or delaminate (separate the layers of) the PCB itself.

The soldering method defines your product’s manufacturability, reliability, and cost. Here’s what you should think about:

Component Mix: Are you using mostly SMT parts? Then you need a partner with a top-tier reflow soldering line. A mix of SMT and through-hole? You need a factory equipped for both reflow and selective wave soldering.

Process Control is Everything: A reflow oven isn't a simple heater. It needs a precise temperature profile tailored to your specific board and solder paste. A good manufacturer constantly monitors this. At Kaboer, our process engineers in Shenzhen treat the reflow profile as a critical recipe for success, fine-tuning it for every project to prevent defects.

Inspection is Non-Negotiable: After soldering, you must verify quality. This means Automated Optical Inspection (AOI) to check for bridges and misalignment, and often X-ray inspection to see hidden solder joints under chips like BGAs. You can’t fix what you can’t see.

Soldering a circuit board is the irreversible step where your design becomes a physical, functional object. Getting it right requires the right method, meticulous process control, and a deep understanding of the materials involved.

For a prototype or a tiny batch, skilled handwork might suffice. But for any serious production, you are investing in a manufacturer's soldering process. You're buying their expertise in chemistry, thermal management, and automated precision.

This is where the integrated advantage of a partner like Kaboer shows. Controlling the entire PCBA process in our own factory means we own the soldering quality from start to finish. We’re not just assembling parts you send us; we’re engineering the thermal profiles, selecting the right solder paste, and inspecting every joint to ensure your product is built on a foundation of reliable connections. Because in the end, every brilliant function of your device depends on the integrity of these tiny, shiny spots of metal.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..