Date: 2026-01-22

Picture this: you're designing a circuit board for a new product. The design is tight, and you've run out of space to route a critical signal on the top layer. The path is blocked by a maze of other traces. What do you do? You can't magically make the board bigger.

This is the exact moment you need a via. It’s the most basic yet essential "escape route" in PCB design.

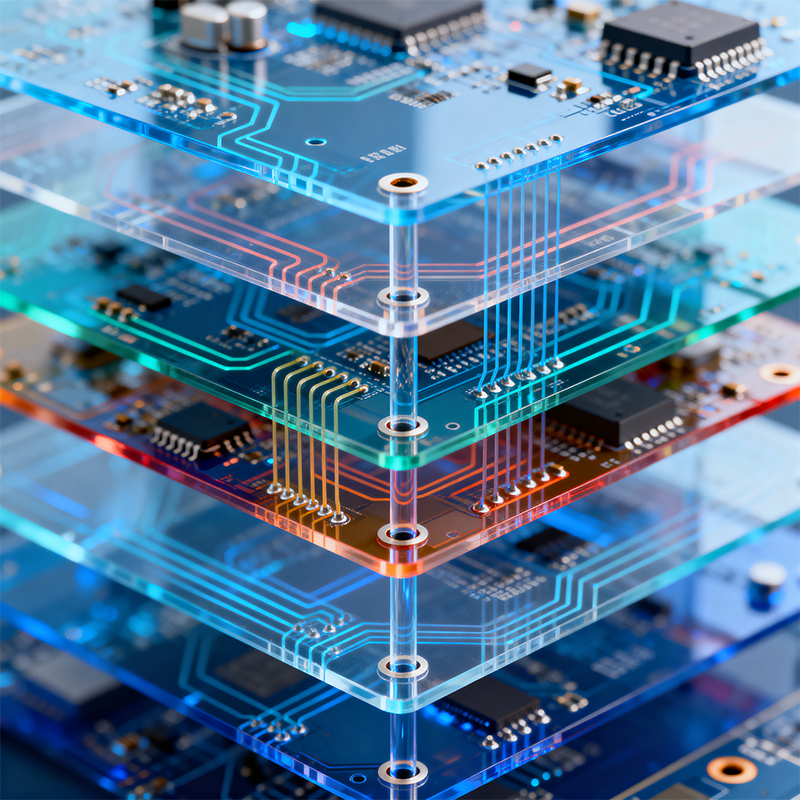

Think of a via as a microscopic elevator or a vertical tunnel inside your circuit board. Its job is simple but vital: to move an electrical signal from one layer of the board to another. Without vias, we'd be stuck with flat, single-layer circuits with extremely limited functionality—think of a 1950s radio instead of a modern smartphone.

To understand a via, imagine a multi-story office building.

Each floor is a layer of copper in your PCB.

The hallways and rooms on each floor are the traces that carry signals.

The staircase or elevator shaft connecting the floors? That's your via.

If someone on the 3rd floor needs to deliver a message to someone on the 1st floor, they don't go outside and re-enter—they take the stairs. A via does exactly that for electricity inside your board.

During the PCB manufacturing process, a tiny hole is drilled (often with a laser for small sizes) through the layers of the board. The inside of this hole is then coated with a thin layer of copper through a process called plating, creating an electrical connection between the layers it passes through. The top and bottom of the hole are connected to the copper traces on their respective layers.

So, it's not just an empty hole; it's a copper-plated cylinder that acts as a conductive pipe.

As designs got more complex, different types of vias were invented to solve specific problems.

1. Through-Hole Via (The Standard)

This is the original and most common type. It's drilled all the way from the top layer to the bottom layer of the board.

Like: A public elevator that goes from the roof to the basement, stopping at every floor.

Pros: Simple, reliable, and cost-effective to manufacture.

Cons: It takes up space on every single layer it passes through, which can block routing paths on the inner layers. On high-density boards, this is a real problem.

2. Blind Via

A blind via connects an outer layer (top or bottom) to one or more inner layers, but it does not go all the way through the board.

Like: A private staircase connecting the penthouse suite to the executive offices on the floor just below. It starts on the top and stops inside the building.

Why use it? It saves precious real estate on the inner layers and opposite outer layer, allowing for much denser and more complex routing. Essential for modern chips with hundreds of pins (like BGAs).

3. Buried Via

A buried via connects inner layers only. It starts and ends inside the board and is completely invisible from the outside.

Like: A secret passageway connecting two interior floors, hidden from the building's facade.

Why use it? This is the ultimate space-saver for incredibly complex, multi-layer boards (think 12+ layers). It maximizes the usable area on the outer layers for component placement.

While their primary function is electrical, vias have secondary effects that every good designer and manufacturer must manage:

Heat Paths: Vias are excellent at conducting heat. Designers often place arrays of vias under hot components (like processors) to act as "thermal vias," pulling heat down into inner ground planes or to the other side of the board where a heatsink can be attached.

Signal Integrity: At very high frequencies (like in 5G or high-speed computing), a via is not just a perfect conductor. It introduces a tiny bit of inductance and capacitance, which can affect signal quality. Careful design is needed for critical high-speed paths.

Manufacturing Cost & Reliability: Each type of via adds cost and complexity. Through-hole vias are cheapest. Blind and buried vias require sequential drilling and lamination steps, which increases cost and fabrication time.

More critically, the plating inside a via must be uniform and free of voids. A poorly manufactured via can crack under thermal stress or fail electrically, leading to a dead board.

This is where your choice of PCB and assembly partner becomes crucial. Vias, especially blind and buried ones, are a litmus test for a fabricator's capabilities.

A manufacturer that cuts corners might have:

Poorly drilled holes causing broken connections.

Incomplete copper plating inside the hole (a "void"), leading to high resistance or an open circuit.

Misalignment between layers for blind/buried vias, rendering them useless.

At Kaboer, with our integrated PCBA factory in Shenzhen, we control the process from the bare board up. This means our engineering team understands the relationship between via design, fabrication quality, and final assembly reliability. We don't just accept a design with potentially problematic vias; we can provide early feedback to ensure your board is not only functional but also manufacturable and robust.

So, what is a via? It's the fundamental three-dimensional component of PCB design. It's what transforms a circuit from a flat, two-dimensional sketch into a complex, multi-layered, high-performance system.

Understanding vias helps you appreciate the hidden complexity inside your electronics and underscores why partnering with a manufacturer that masters these microscopic details is key to turning a great design into a reliable, high-yielding product. It's a small feature that makes a world of difference.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..