Date: 2026-01-24

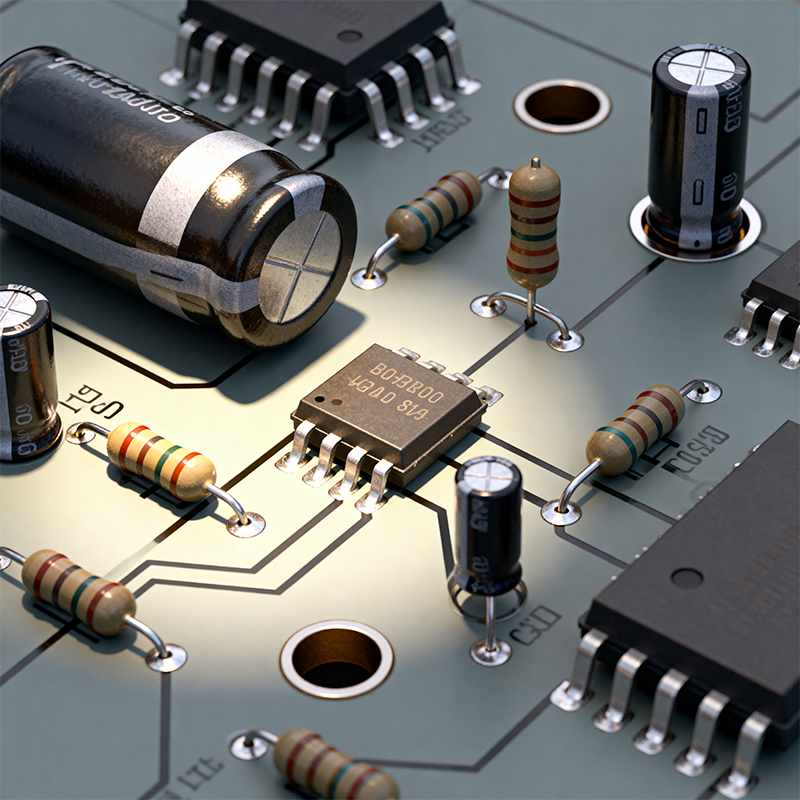

Let's talk about a technology that many consider “old-school,” but which is far from obsolete. In a world dominated by tiny, surface-mounted chips, through-hole assembly is the reliable, sturdy foundation that still anchors countless electronic products. It’s the method where components have wire leads that are inserted through holes drilled in the PCB and soldered on the opposite side.

Think of it this way: if surface-mount technology (SMT) is like using high-tech stickers to attach parts, then through-hole assembly is like using nuts and bolts. It’s a physical, mechanical connection that’s incredibly hard to shake loose.

The process is straightforward and hasn’t changed much in decades, which is a testament to its effectiveness.

Component Placement: A technician (or, in automated setups, a special machine) takes a component with long, wire-like leads—think a large capacitor, a sturdy connector, or a power transformer—and inserts those leads through the corresponding holes in the bare circuit board.

Soldering: The backside of the board, where the leads poke through, is then soldered. This was traditionally done by hand with a soldering iron. For production, the most common method is wave soldering, where the bottom of the board passes over a flowing wave of molten solder, which wicks up into every hole at once, creating all the connections in a single pass.

Trimming: After soldering, the excess length of the component leads is clipped off, leaving a clean finish.

You might wonder, if SMT is so much smaller and faster, why does through-hole still exist? Because it solves problems that SMT can’t.

The Unbeatable Advantages:

Mechanical Strength Supreme: This is the #1 reason. A through-hole component is locked in place both by solder and by the physical hole in the board. It can withstand tremendous physical stress, vibration, and shock. This is why you’ll always find through-hole connectors, sockets, and large transformers in products that get plugged, unplugged, or shaken.

Power Handling Champion: Components that need to handle high power or get very hot—like large resistors, certain inductors, and power regulators—are often through-hole. Their leads and the board’s plated holes can conduct more heat away from the component body than a tiny SMT pad.

Prototyping & Repair Friendliness: For engineers breadboarding a new idea or technicians fixing a broken device, through-hole components are much easier to handle, solder, and replace by hand. There’s no need for a hot-air rework station.

The Trade-offs (The “Yes, But…”):

It Takes Up Real Estate: The holes and the space needed for the soldered connections on the bottom layer consume valuable board space on both sides of the PCB. This limits how small you can make a device.

It’s Slower and More Manual: Even with automated insertion and wave soldering, it’s generally a slower process than high-speed SMT lines that place tens of thousands of parts per hour. For pure through-hole boards, labor costs can be higher.

Extra Manufacturing Step: It requires the PCB fabricator to drill all those holes, which adds a step that pure SMT boards don’t need.

Very few modern electronic devices use only through-hole or only SMT. The smartest designs use mixed-technology assembly, placing each type of component where it makes the most sense.

The main logic board of your router is covered in SMT chips for computing and memory.

But the power input jack, the Ethernet ports, and the large electrolytic capacitors near the power supply? Those are almost certainly sturdy through-hole parts.

This hybrid approach gives you the best of both worlds: the miniaturization and speed of SMT for the brain of the device, and the brute-force reliability of through-hole for the parts that interface with the outside world or handle tough jobs.

Through-hole assembly is not a technology of the past; it’s a technology of permanence and strength. It’s the right choice when your priority is mechanical reliability, high power, or ease of manual handling.

When you’re designing a product, ask yourself about each component: Does this part need to survive being yanked, vibrated, or heated up? Will a human ever need to replace it? If the answer is “yes,” then the dependable, bolt-like grip of through-hole technology is likely your best bet. It’s the classic technique that continues to hold the electronics world together, one strong solder joint at a time.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..