Date: 2026-01-27

Imagine you’ve just received a batch of freshly made circuit boards. Before they go into your expensive assembly line or out the door to a customer, you need to be sure they work perfectly. But what if you only have a few boards, or the design changes often? Building a custom test fixture might be too slow and costly. Enter the Flying Probe Tester—think of it as a nimble, robotic doctor that can give your PCBs a thorough checkup without any special setup.

What is a Flying Probe Tester?

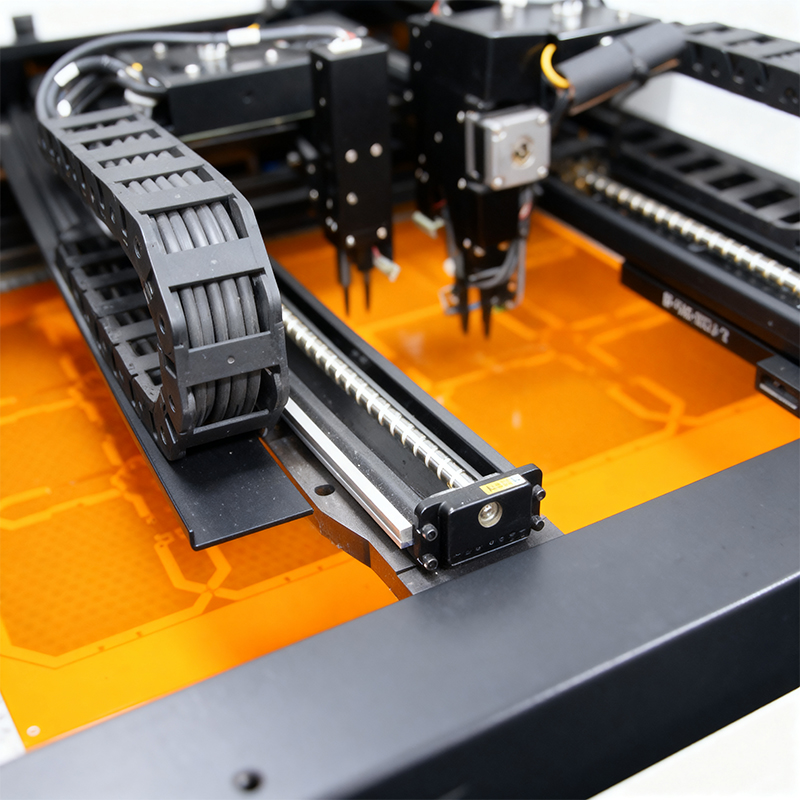

Simply put, it’s a machine that uses two or more movable, robotic “probes” (like fine-tipped needles) to make contact with test points on a bare circuit board. These probes “fly” across the board surface, touching down on pads and traces to measure electrical continuity, resistance, capacitance, and other basic properties. It’s looking for manufacturing defects like short circuits, open circuits, or missing components.

How It Works: A Quick Look

Programming: First, you feed the tester the board’s design file (like Gerber or CAD data). The software figures out where all the test points are.

Setup: You simply place the bare board on the machine’s bed. No custom fixtures or “bed of nails” required.

Testing: The robotic arms move the probes from point to point with high precision. One probe might send a tiny signal, and another probe elsewhere will check if it’s received correctly, verifying the connection.

Key Advantages for Electronics Makers

No Custom Fixtures Needed: This is the biggest win. You skip the time and cost of designing and machining a dedicated test fixture (a “bed of nails”).

Perfect for Prototypes & Low Volumes: Ideal for new product introductions, small batches, or boards that are frequently revised. You can test a board the day you get it from the fab.

Flexibility: Can easily handle complex boards with high-density components and fine-pitch parts where traditional fixtures struggle.

Quick Turnaround: Changing the test program for a new board design is just a software update.

The Trade-offs: What to Keep in Mind

Speed: It’s much slower than a traditional fixture tester (which checks thousands of points simultaneously). Flying probes test points sequentially, one or a few pairs at a time. It’s not ideal for high-volume production line speed.

Limited Test Coverage: It’s primarily for testing the “bare board” (continuity, shorts, opens) and basic in-circuit checks on assembled boards. It’s not great for functional testing that simulates real-world operation.

Probe Wear: The physical probes eventually wear out and need replacement.

When Should You Consider Using One?

Ask yourself these questions:

Are you dealing with prototypes, pre-production runs, or low-to-medium volumes?

Is your board design changing often?

Do you need to start testing immediately without waiting weeks for a custom fixture?

Is your board very complex or densely packed?

If you answered “yes” to most of these, a flying probe test is likely an excellent, cost-effective choice for your quality control process.

In short, the flying probe tester is the agile, adaptable problem-solver of the PCB test world. It won’t win a race against a dedicated fixture tester on a massive production line, but for flexibility, quick setup, and handling complex designs, it’s an indispensable tool that keeps your development moving fast and your quality high.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..