The Right Ways to Cool Flexible PCBs

Date: 2025-08-11

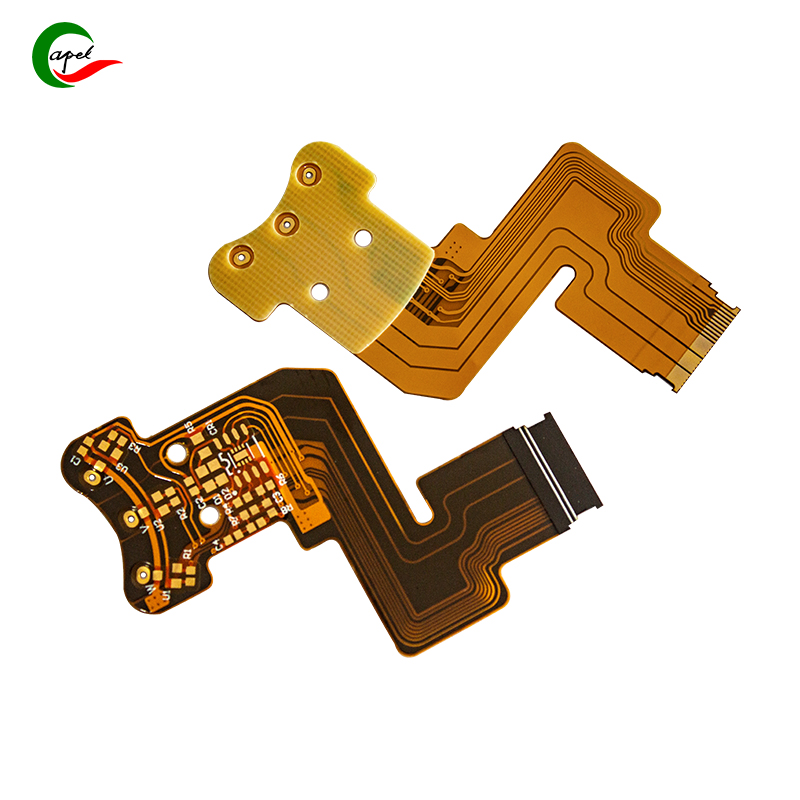

Flexible PCBs are champions of fitting into tight, curved spaces, but their thin, lightweight design comes with a trade-off: heat buildup. Unlike rigid PCBs, which can rely on thick copper layers or bulky heat sinks, flexible PCBs need cooling solutions that won’t ruin their flexibility. Here’s how to keep them cool without sacrificing their most valuable trait.

Copper isn’t just for conducting electricity—it’s also a natural heat conductor. Smart copper design can turn the PCB itself into a cooling tool.

- Widen Power Traces: Thick, wide copper traces (0.2mm or more) carry more current and spread heat faster than narrow ones. In high-power devices like LED strips or battery management systems, using extra-wide traces near heat-generating components (chips, resistors) helps pull heat away from hot spots.

- Add Copper Planes: A continuous copper plane (a large, unbroken area of copper) acts like a built-in heat spreader. Even in flexible PCBs, a thin copper plane (12–35μm) across one layer distributes heat evenly, preventing localized overheating. This is key for 5G modems or IoT sensors that cram powerful chips into small spaces.

Traditional rigid heat sinks (like aluminum blocks) are too stiff for flexible PCBs, but flexible alternatives get the job done without restricting movement.

- Thermal Tape with Conductive Fillers: Thin, flexible thermal tapes (filled with graphite or aluminum particles) stick to hot components and transfer heat to the surrounding air. They’re perfect for wearables like smartwatches, where bulk is a no-go—think of them as "heat stickers" that bend with the PCB.

- Graphite Sheets: Graphite is lightweight, flexible, and conducts heat 10x better than copper. Attaching a thin graphite sheet (as thin as 0.1mm) to the PCB’s surface pulls heat away and spreads it over a larger area. This works wonders in foldable phones, where the PCB bends but still needs to cool the processor during heavy use.

The device’s case or housing can double as a heat sink—no extra hardware needed.

- Thermal Bonding to Enclosures: If the PCB sits close to a metal or plastic enclosure, use a thermal adhesive to bond them. The enclosure acts as a large heat spreader, radiating heat into the air. This is common in electric vehicle (EV) battery packs, where flexible PCBs manage cell temperatures and bond to the metal battery casing for cooling.

- Ventilation Design: For devices with moving parts (like robotic arms), design the enclosure with small vents near the PCB. Even a little airflow can carry away heat, especially when paired with a graphite sheet to direct heat toward the vents.

Sometimes the best cooling is preventing excess heat in the first place.

- Component Placement: Keep high-power components (like voltage regulators or LEDs) spread out, not clustered. Crowding them creates hot zones that even good cooling can’t fix. In flexible PCBs for medical devices (e.g., portable monitors), spacing components ensures heat doesn’t build up near sensitive sensors.

- Choose Low-Power Alternatives: Swap out heat-generating parts for energy-efficient versions. A low-power microchip might cost a bit more, but it reduces the cooling load—critical for devices like wireless earbuds, where there’s no room for extra cooling layers.

For high-heat applications (like industrial machinery or aerospace gear), where passive cooling isn’t enough, flexible liquid cooling lines can step in.

- Thin, Flexible Tubes: Run tiny silicone tubes (as thin as 2mm) along the PCB, carrying coolant (like water or mineral oil). These tubes bend with the PCB and absorb heat, which is then dissipated by a small radiator elsewhere in the device. It’s overkill for most consumer tech but a lifesaver in factory robots or satellite systems, where PCBs operate in tight, hot spaces.

The goal isn’t to make flexible PCBs as cool as rigid ones—it’s to keep them cool enough without making them stiff or bulky. Whether it’s using graphite sheets in a foldable phone or thermal tape in a smartwatch, the best solutions work with the PCB’s flexibility, not against it. By combining smart design (copper planes, spread-out components) with flexible cooling tools, you can keep these bendable circuits running smoothly—even when the heat is on.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.