Date: 2026-01-22

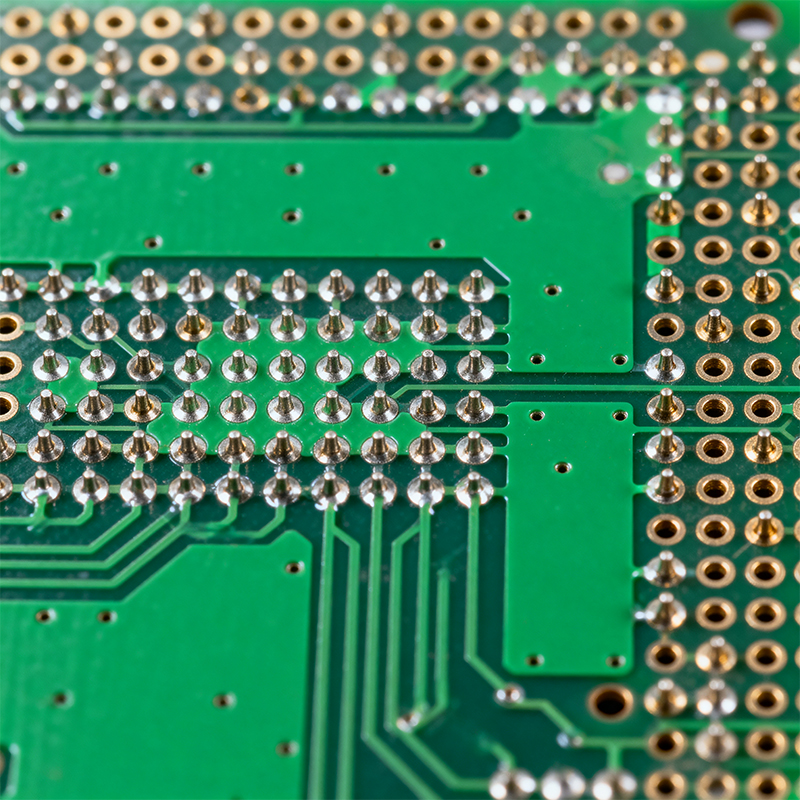

Look at any modern circuit board—the green (or sometimes blue, red, or black) board inside your electronics. What you're seeing isn't the actual copper wiring; it's a protective coating called the solder mask. And if circuit boards had unsung heroes, this thin layer of polymer would be it.

Think of it this way: If the copper traces on a PCB are like the intricate wiring inside your house's walls, then the solder mask is the protective insulation and drywall that keeps everything safe, organized, and prevents accidental shorts. Without it, assembling modern electronics would be nearly impossible.

Let's pull back this green curtain and see what the solder mask really does and why it matters so much for your products.

The solder mask (also called solder resist or solder stop mask) is a thin, durable layer of polymer (usually a type of epoxy) that is applied over the entire surface of a manufactured PCB. Its job is to cover and protect all the copper traces except the specific spots where components need to be soldered—those exposed metal pads and holes.

Imagine you're a painter. You've laid down the copper "wires" (the traces) on a blank board. Now, you need to protect most of that work, leaving only specific "dots" and "squares" exposed for connections. You'd use a high-precision stencil and a special, tough paint. That's essentially what the solder mask process is.

This coating isn't just for looks. It has three critical jobs:

This is its primary mission. On a dense, modern PCB, copper traces can run incredibly close to each other. During the solder paste printing and reflow soldering stages of SMT assembly, molten solder is everywhere. Without the solder mask, this solder could easily bridge between two traces, creating a short circuit and a dead board. The mask acts as a physical barrier, confining the solder only to the designated pads.

Bare copper is vulnerable. It can oxidize (tarnish) when exposed to air and moisture, leading to poor solderability and eventual corrosion. It's also susceptible to damage from dust, chemicals, and minor scratches during handling. The solder mask seals the copper away from the world, dramatically improving the board's long-term reliability and shelf life.

By clearly defining where solder should and should not go, the mask is a huge help to both automated assembly machines and human technicians. It provides high visual contrast, making it easy for pick-and-place machines and AOI (Automated Optical Inspection) systems to "see" the board accurately. For a technician doing rework, the non-stick properties of the mask help prevent solder from sticking where it's not wanted.

It's not always green, but that's the classic, default color for a few practical reasons:

Historical Preference: It was the original, most readily available formulation with good properties.

Eye Comfort & Contrast: Green provides excellent contrast against white silkscreen (component labels) and shiny silver solder joints, reducing eye strain for inspectors over long shifts.

Reliable Performance: The classic green epoxy formula is known for its reliability and cost-effectiveness.

Today, you see many colors: blue for internal boards in graphics cards, red for hobbyist boards, black for high-end consumer electronics (it looks sleek but is harder to inspect), white for LED boards to reflect light, and even yellow or purple. The color is a dye added to the base polymer and generally doesn't affect the core protective function—though some exotic colors can cost a bit more.

This is where manufacturing quality shines through. A poor-quality solder mask, or a poorly applied one, can cause big headaches:

Misalignment: If the mask openings aren't perfectly aligned with the copper pads, it can cover part of the pad (making soldering difficult) or leave too much trace exposed (increasing short risk).

Bubbles, Peeling, or Scratches: Low-quality material or improper curing can lead to defects that compromise protection and look unprofessional.

Insufficient Thickness: A mask that's too thin might not prevent solder bridging between very fine-pitch components.

A high-quality PCB manufacturer will have tight control over this process, using methods like Liquid Photo-Imageable (LPI) solder mask, which is applied as a liquid and then exposed to UV light through a film to create incredibly precise openings.

Why should you, as a device manufacturer, care about this seemingly minor detail? Because the quality of the solder mask is a foundational element of your PCBA's success.

When you partner with a PCBA manufacturer like Kaboer, you're not just getting components soldered onto a board you sourced elsewhere. We oversee the entire process, starting with the fabrication of the bare PCB itself. This means we specify and qualify the solder mask material and process to ensure it's perfectly suited for your assembly needs.

For instance, if your design has very fine-pitch chips (like a 0.4mm pitch BGA), we know the solder mask dam between pads must be flawless. If you're doing a white board for an LED product, we understand the reflectance properties needed. This integrated control from bare board to finished assembly prevents the "finger-pointing" that can happen when PCB fabrication and assembly are split between different vendors.

The solder mask is a perfect example of a small thing that makes a huge difference. It's the quiet, dependable layer that enables the complexity, reliability, and manufacturability of every electronic device we use today.

When you're reviewing a PCB or PCBA, take a closer look at that green (or blue, or black) coating. Its precision and quality are a direct reflection of the care and expertise that went into making it—a small but telling sign of a well-built foundation for your product.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..