Date: 2026-01-15

You're probably searching for "copper PCB" because you're wrestling with a tough design—maybe a high-power LED driver, an automotive power module, or an industrial controller that needs to handle tens of amps. You have a feeling that standard 1-ounce (35μm) copper won't cut it, but you're unsure about the specifics and worried about costs spiraling. This is exactly where we need to start untangling things together.

In the industry, the term "copper PCB" is actually quite broad. It could point to three very different things, with huge variations in cost, process, and application:

1. Heavy Copper PCB

This is the most common scenario. "Standard" PCBs use 1-ounce (≈35μm) copper foil. When copper thickness reaches 3 ounces (105μm) or more, it typically falls into the "heavy copper" category. What's called "extreme heavy copper" can go up to 10 ounces (350μm) or higher. The entire board isn't that thick; instead, specialized plating processes build up copper on specific traces (inner or outer layers).

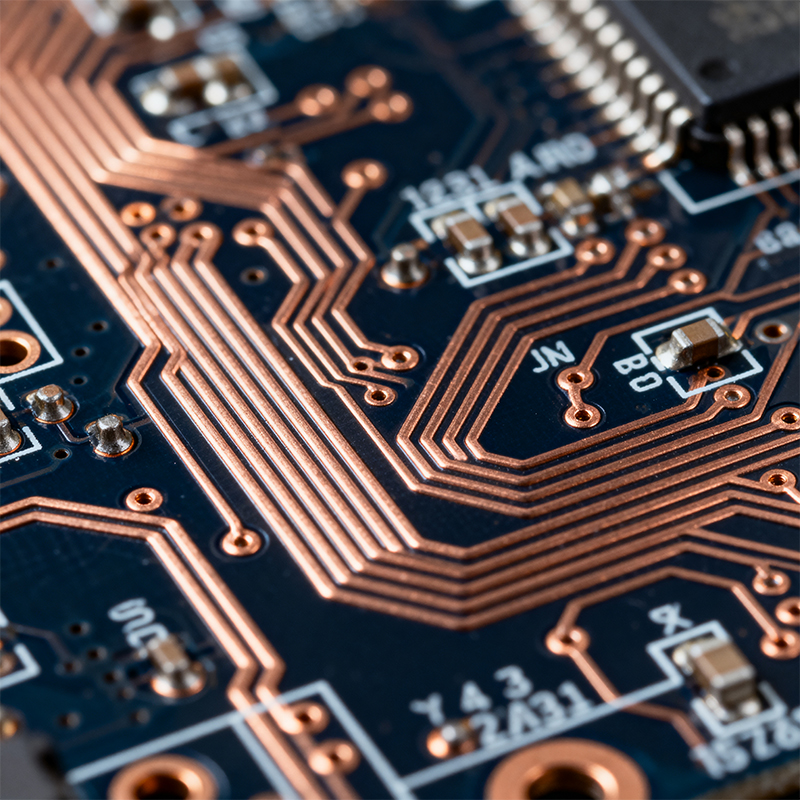

What does it look like? If you see a PCB where the power traces appear noticeably raised with rounded edges, it's likely a heavy copper design.

Typical Applications: High-power inverters, welding equipment power supplies, high-power motor drives.

2. Copper Core PCB (Metal Core PCB - MCPCB)

This is a completely different structure. It's typically a three-layer sandwich:

Top Layer: Circuit layer (copper foil).

Middle Layer: Thermally conductive but electrically insulating dielectric (often a high-performance polymer).

Bottom Layer: A solid, thick metal baseplate (usually aluminum, but copper for high-performance needs).

Why is it special? Its core strength is heat dissipation, not carrying enormous current. The metal base acts like an efficient heat spreader, pulling heat away laterally.

Typical Applications: High-power LED lighting, automotive headlights, packaging substrates for certain power modules.

3. Solid Copper Inlays Embedded in PCB

This is a more specialized process where a cavity is routed into the PCB, and a solid copper block is pressed into it. This is used for points requiring extremely low impedance and maximum heat dissipation, like high-current connection points or directly under power devices.

Typical Applications: Certain high-end server power supplies, high-current junctions in telecom equipment.

When you feel you need a "copper PCB," start by asking this key question: Is my primary challenge current, or heat?

If the primary challenge is "High Current" (e.g., your design needs to carry over 50A continuously or withstand frequent surges):

Your path is likely Heavy Copper PCB. You'll need to focus on: designing wide enough traces, calculating temperature rise, selecting the right copper weight (like 3oz, 5oz, 10oz), and managing the manufacturing challenges that come with it.

If the primary challenge is "High Heat" (e.g., your LED efficiency and lifespan are critically tied to junction temperature, or your MOSFETs/IGBTs are derating due to poor cooling):

Your path is more likely Copper Core PCB (MCPCB). You'll need to focus on: the thermal conductivity of the dielectric layer, the thickness of the metal base, and how to efficiently transfer heat to the enclosure or heatsink.

Often, both challenges exist together, requiring a combined approach or a hybrid solution.

If you go the heavy copper route, these issues are unavoidable:

1. Etching Precision and Undercut

The thicker the copper, the more pronounced the lateral etching ("undercut"). This means your finished trace will be narrower than designed. You must compensate for this in your design. For instance, for a target 0.5mm trace, you might need to design it at 0.6mm. This heavily relies on the manufacturer's experience and data.

2. Lamination and Resin Filling

When inner layers have thick copper traces, resin struggles to fill the deep channels between them during lamination, potentially creating voids. This affects reliability and can lead to high-voltage breakdown risks. Good manufacturers use High Resin Content (High RC) prepreg and optimize lamination cycles to address this.

3. Drilling and Plated Hole Reliability

Drilling a hole through a thick copper board is like creating a deep well. Ensuring the walls of this "well" are plated with a uniform, sufficient thickness of copper for current carrying and reliability is a major challenge for the plating process. Hole copper thickness and uniformity must be strictly controlled.

4. Surface Finish and Soldering

Thick copper pads have high thermal mass, requiring a carefully tuned reflow profile to prevent cold solder joints. Also, some finishes (like HASL) can be more prone to solder webbing on thick copper edges.

Once you know your direction, how you communicate with the fab will make or break your project. Here are some key phrases and points:

Don't just say: "I need a copper PCB."

Instead, be specific: "We're designing a motor driver where the main power path needs to carry 80A continuous, with 150A transients. We're considering 4-ounce copper for the power layers and would like your advice on cost and manufacturability. Attached is our preliminary stack-up idea."

Ask detailed, process-focused questions:

"For inner layers above 3oz, what is your standard etch compensation factor?"

"How do you ensure resin fill quality after lamination for heavy copper inner layers? Can you provide cross-section reports?"

"Do you adjust the SMT reflow profile for boards with thick copper pads?"

"What are your minimum trace/space capabilities for different copper weights?"

In our factory, processing heavy copper boards (especially 4oz+) is treated as a "special process." What we've learned:

Data is more valuable than general experience. Every factory's equipment and chemistry are different, so their compensation factors are unique. We've built a database of compensation values for different copper weights and trace widths specific to our line—this is fundamental to getting what you design.

The value of upfront DFM is huge. A client once designed their own 6oz heavy copper traces with a 0.3mm/0.3mm trace/space. Our DFM engineer flagged that this would be near impossible to produce reliably on our line. After discussion, we adjusted the design to 0.4mm/0.4mm and tweaked some shapes, leading to successful production and saving the client a major headache.

Testing must be robust. For heavy copper boards, beyond standard electrical testing, we sample and physically test the current-carrying capacity of key high-current traces to ensure temperature rise is within spec. It's an extra layer of quality assurance.

The journey of searching for "copper PCB" is essentially about refining a vague need ("my board needs to handle a lot of current") into an executable technical plan ("I should use a 4oz heavy copper design with Xmm of compensation, paying attention to Y process points").

Understanding the technical differences and manufacturing challenges doesn't just help you make a better choice—it empowers you to communicate effectively with your supplier. Together, you can build a product that meets performance requirements while being reliable and manufacturable.

If you're evaluating a high-power project and aren't sure which path is best, or if you have a preliminary design and want a second opinion on manufacturability, we're always happy to share our perspective.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..