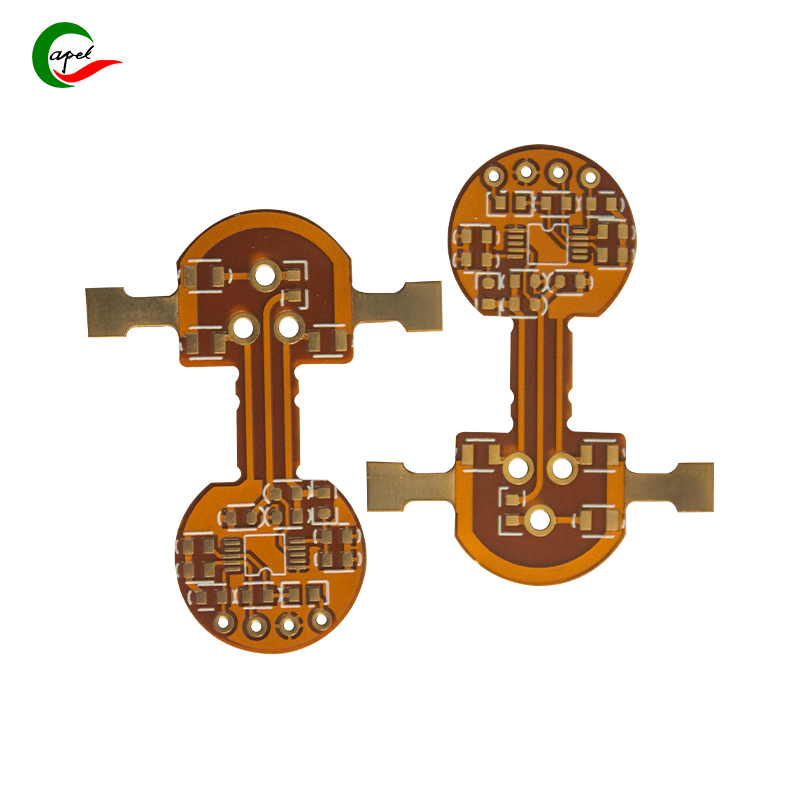

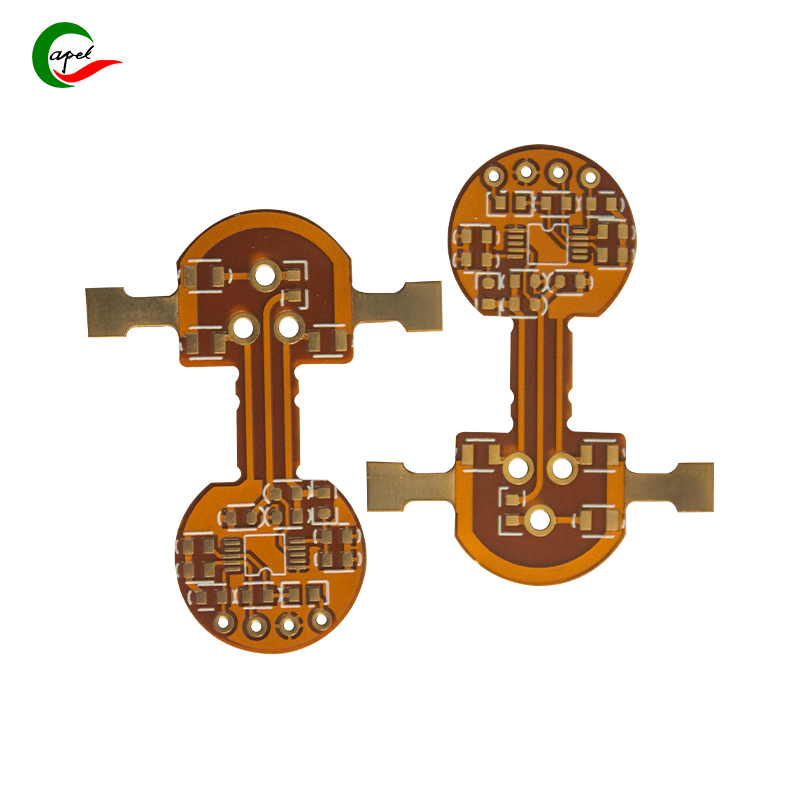

Flexible printed circuits (FPCs) are celebrated for their ability to bend, twist, and fit into tight spaces—think the hinge of a foldable phone or the curve of a smartwatch. But this flexibility comes with a trade-off: vulnerability. In critical areas like connector tabs, component mounting zones, or spots prone to repeated stress, FPCs need extra strength to avoid tearing, cracking, or failing. That’s where FPC reinforcement plates come in. These small, strategic additions are the unsung heroes that make flexible circuits durable enough for real-world use. Let’s break down what they are, the forms they take, and why they’re indispensable.

What Exactly Is an FPC Reinforcement Plate?

At its core, a reinforcement plate is a rigid or semi-rigid material bonded to specific areas of an FPC to add structural support without sacrificing the circuit’s overall flexibility. Think of it like adding a steel patch to a leather belt—only the stressed part gets reinforced, while the rest stays supple.

Reinforcement plates are typically thin (0.1mm to 1mm) and cut to match the exact shape of the area they’re strengthening. They’re attached using adhesives (epoxy or acrylic) that bond securely to the FPC’s substrate (like polyimide) without interfering with electrical signals.

The Most Common Types of Reinforcement Materials

Not all reinforcement plates are the same—material choice depends on the FPC’s environment, function, and stress levels. Here are the top options:

1. FR4: The Workhorse of Reinforcements

- What it is: FR4 is a glass-reinforced epoxy laminate—the same material used in rigid PCBs. It’s strong, heat-resistant (up to 302°F/150°C), and electrically insulating.

- Why use it: FR4 is the go-to for most FPCs, especially in consumer electronics and automotive applications. It adds rigidity to connector tabs (where plugs are inserted repeatedly) or areas mounting components like resistors or sensors. For example, the FPC in your phone’s charging port likely uses FR4 reinforcement to withstand thousands of plug-ins.

- Bonus: FR4 is cost-effective and easy to machine, making it ideal for high-volume production.

2. Stainless Steel: For Extreme Durability

- What it is: Thin stainless steel foils (0.1mm to 0.3mm) offer unmatched tensile strength and resistance to corrosion.

- Why use it: In industrial or automotive FPCs exposed to vibration, moisture, or physical abuse—like the circuits in factory robots or car door sensors—stainless steel reinforcement prevents tearing. It’s also conductive, which can help shield sensitive signals from electromagnetic interference (EMI) in high-noise environments.

3. Polyimide (PI): Reinforcement with Heat Resistance

- What it is: PI is the same material used in high-performance FPC substrates, but in thicker sheets (50μm to 200μm) for reinforcement.

- Why use it: When an FPC operates in extreme heat (e.g., under a car hood or near a battery pack), PI reinforcement keeps up—it withstands temperatures up to 752°F (400°C) without degrading. It’s flexible enough to bend slightly, making it perfect for areas that need both strength and a little give, like the hinges of foldable laptops.

4. Aluminum: Lightweight Strength

- What it is: Thin aluminum sheets (0.1mm to 0.5mm) offer a balance of strength, light weight, and cost.

- Why use it: In portable devices like tablets or wearables, where weight matters, aluminum reinforcement adds support without adding bulk. It’s also a good conductor of heat, helping dissipate warmth from power-hungry components like microchips.

5. Specialized Materials: For Niche Needs

- Ceramic: Used in high-frequency FPCs (like 5G antennas) where electrical insulation and low signal loss are critical.

- Kapton (PI film) with adhesive: A semi-rigid option for FPCs that need moderate reinforcement but still require some flexibility, such as medical sensors wrapped around joints.

The Critical Roles of FPC Reinforcement Plates

Reinforcement plates aren’t just "extra strength"—they solve specific, often mission-critical problems:

1. Preventing Mechanical Failure

FPCs are thin (often 0.1mm to 0.3mm total), and repeated bending or stress can cause their copper traces or substrate to fatigue and crack. Reinforcement plates distribute stress across a larger area, reducing strain on vulnerable spots. For example:

- In a foldable phone’s hinge FPC, PI or stainless steel reinforcement along the bend line prevents the circuit from snapping after 100,000+ folds.

- In a drone’s battery FPC, which bends during flight, FR4 reinforcement keeps the power connectors from tearing loose.

2. Ensuring Reliable Connections

Connector tabs (the parts of an FPC that plug into ports or other circuits) are under constant stress. Every time you plug in a charger or a data cable, the tab flexes slightly. Without reinforcement:

- The tab could warp, leading to loose connections or intermittent power.

- The copper traces near the connector could break, killing the circuit entirely.

FR4 or stainless steel reinforcement keeps the tab rigid, ensuring a tight, consistent fit—critical in automotive FPCs (where a loose sensor connection could disable ADAS) or medical devices (where a failed connection might interrupt vital monitoring).

3. Supporting Component Mounting

Surface-mount components (SMDs) like ICs, capacitors, or LEDs add weight and stress to an FPC. Without reinforcement:

- The FPC could sag under the component’s weight, causing solder joints to crack.

- Heat from soldering (up to 572°F/300°C) could warp the FPC, misaligning the component.

Reinforcement plates provide a stable platform for soldering, ensuring components stay in place even during temperature cycles or vibration. This is especially important in automotive FPCs, where components must survive 10+ years of road abuse.

4. Enhancing Manufacturing Precision

During assembly, FPCs are often handled by robotic arms or inserted into fixtures. A floppy, unreinforced FPC can twist or misalign, leading to assembly errors. Reinforcement plates add rigidity, making it easier to:

- Position the FPC accurately in automated pick-and-place machines.

- Insert tabs into connectors without bending or damaging them.

This reduces manufacturing defects and speeds up production—key for high-volume products like smartphones or EV battery packs.

When Is Reinforcement Not Needed?

Not every FPC requires reinforcement. Simple, low-stress circuits—like the flex cables in a basic remote control—may get by without it. But for any FPC that:

- Bends repeatedly (e.g., foldables, wearables)

- Has connectors (e.g., charging ports, sensor plugs)

- Mounts heavy components (e.g., microchips, batteries)

- Operates in harsh environments (e.g., cars, industrial settings)

Reinforcement is non-negotiable.

Conclusion: Small Plates, Big Impact

FPC reinforcement boards may be unassuming, but they are the reason flexible circuits work in the real world. By adding targeted strength where it’s needed most, they turn delicate, bendable designs into durable, reliable components—capable of surviving the rigors of daily use, extreme temperatures, and constant motion.

For engineers designing the next generation of electronics, ignoring reinforcement is a risk. The right plate, in the right place, can mean the difference between a product that fails after months and one that lasts for years. In the end, reinforcement plates are more than just additions—they’re the reason flexible circuits live up to their promise.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.