If you’ve ever wondered how foldable phones bend without breaking, or how tiny smartwatches fit sensors, batteries, and screens in a small case, the answer often lies in rigid-flex PCBs. For beginners new to electronics design, rigid-flex PCBs can seem complex—but they’re simply a hybrid of two familiar technologies: rigid PCBs (the stiff, flat boards in most gadgets) and flexible FPCs (the bendable circuits in wearables). This guide breaks down what rigid-flex PCBs are, where they’re used, and why they’re a game-changer for modern devices.

Let’s start with the basics:

- A rigid PCB is the stiff, flat board you’ll find in laptops or TVs—made of rigid materials like FR-4, it’s great for mounting heavy components (chips, connectors) but can’t bend.

- A flexible FPC is a thin, bendable circuit made of polyimide (PI) film—used in wireless earbuds or smart bands, it fits tight spaces but can’t support heavy parts.

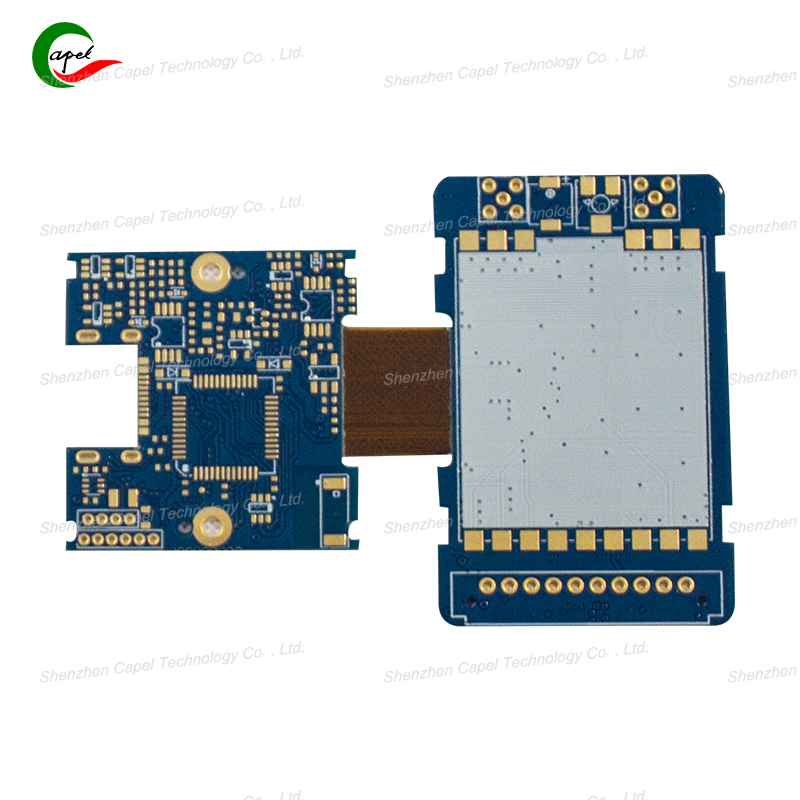

A rigid-flex PCB combines these two: it has rigid sections (for components) connected by flexible zones (for bending or shaping), all in one single board. Think of it like a book— the rigid “covers” hold the “pages” (components), and the flexible “spine” (flex zone) lets it open and close without breaking.

Unlike separate rigid PCBs linked by wires, rigid-flex PCBs are one piece. This eliminates messy wiring, reduces size, and makes the board more durable. For example, a rigid-flex PCB for a foldable phone has rigid sections holding the screen and processor, connected by a flexible spine that bends 200,000+ times.

Rigid-flex PCBs aren’t just for “high-tech” gadgets—they’re used in everyday devices where space, flexibility, or durability matters. Here are the most common uses beginners should know:

Wearables need to be small, lightweight, and bend with your body. A smartwatch’s rigid-flex PCB has:

- Rigid sections: Mount the battery, heart rate sensor, and display (heavy components that need stability).

- Flexible zones: Curve around the watch’s case or bend with your wrist—something a rigid PCB could never do.

Without rigid-flex PCBs, smartwatches would be bulky (with separate rigid boards linked by wires) or uncomfortable (with stiff circuits digging into your skin).

Foldable phones rely on rigid-flex PCBs to bend without breaking. The flexible zone in the hinge connects the two rigid screen sections, letting the phone fold flat while keeping all functions (touchscreen, cameras) working.

Wireless earbuds (the size of a fingertip) also use rigid-flex PCBs: the rigid section holds the speaker and battery, and the flexible zone fits around the earbud’s curved case—saving space that would be wasted on wires.

Cars have tight, irregular spaces—like the door panel or dashboard. A car’s infotainment system uses a rigid-flex PCB where:

- Rigid sections: Hold the touchscreen controller and Bluetooth chip.

- Flexible zones: Route around the dashboard’s curves, avoiding the need for bulky wire harnesses.

This not only saves space but also reduces failure risks—wires in cars can fray from vibration, but rigid-flex PCBs’ one-piece design is more durable.

Medical devices need to be small, reliable, and (often) body-friendly. A hearing aid’s rigid-flex PCB has a rigid section for the amplifier (a heavy component) and a flexible zone that bends to fit the ear canal.

Glucose monitors (worn on the skin) use rigid-flex PCBs too— the flexible zone conforms to the skin, while the rigid section holds the sensor and wireless transmitter.

For beginners, the biggest question is: “Why not just use rigid PCBs or FPCs alone?” Here are the top benefits that make rigid-flex PCBs the better choice for many projects:

Traditional setups use multiple rigid PCBs linked by wires and connectors—all of which take up space. A rigid-flex PCB replaces these with one board: the flexible zones eliminate wires, and the one-piece design cuts down on “dead space” (gaps between separate boards).

Example: A wireless earbud using a rigid-flex PCB is 30% smaller than one with two rigid PCBs and wires.

Wires and connectors are the weakest parts of many electronics—they can loosen, fray, or corrode. Rigid-flex PCBs have no external wires or connectors, so there are fewer things to break.

Test case: A car’s door control system with a rigid-flex PCB has a 50% lower failure rate than one with separate rigid boards and wires (since there’s no risk of wire fraying from door movement).

Rigid PCBs are flat—they can’t fit into curved or irregular spaces (like a smart ring’s circular case). FPCs are flexible but can’t hold heavy components. Rigid-flex PCBs combine both: the flexible zones fit odd shapes, while the rigid sections support components.

Example: A smart ring’s rigid-flex PCB wraps around the ring’s inner circle (flexible zone) and has a tiny rigid section for the battery—something no other circuit board could do.

Wires, connectors, and brackets add weight. A rigid-flex PCB eliminates these, making devices lighter. For wearables, this means more comfort (no heavy wires digging into your wrist). For cars, lighter weight improves fuel efficiency.

Example: A car’s infotainment system with a rigid-flex PCB weighs 40% less than one with traditional rigid boards and wires.

Rigid-flex PCBs aren’t always necessary—they cost more upfront than standard rigid PCBs. They’re a good choice if your project needs:

- Flexibility (to bend or fit odd shapes).

- Small size (no space for wires/connectors).

- Durability (to handle movement or vibration).

If your project is simple (like a basic LED light) and doesn’t need flexibility, a standard rigid PCB is cheaper and easier to work with. But if you’re designing a wearable, foldable device, or something that needs to fit in a tight space, rigid-flex PCBs are worth the investment.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.