Date: 2025-07-10

Discover the complex etching process of 2-layer flexible circuit boards with Kaboer, a leader with 16 years of experience. Learn the importance of precision, advanced technology and proactive solutions to achieve high-quality etched circuit boards.

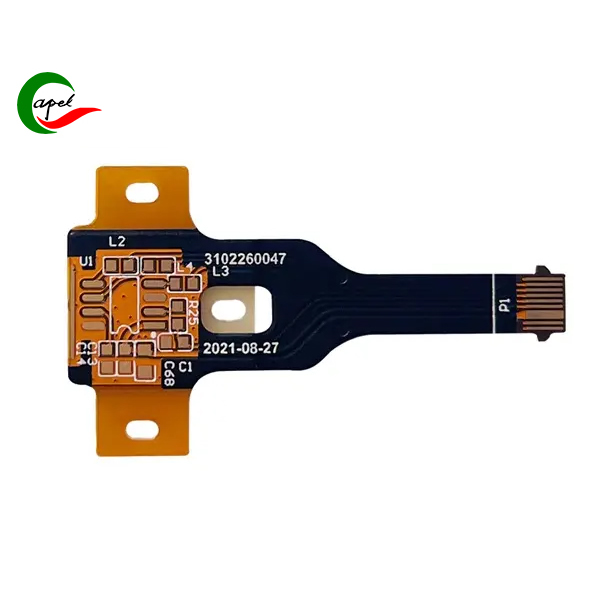

In the electronics world, 2-layer flexible circuit boards have become indispensable due to their ability to fit into complex designs and tight spaces. These boards are widely used in industries such as aerospace, medical devices, and consumer electronics.

The etching process is a critical step in 2-layer flexible circuit board manufacturing. It involves removing unwanted copper from the board to create the desired circuit pattern. Precision and accuracy in this process are critical to ensuring the functionality and reliability of the final product.

With 16 years of industry experience, Kaboer has become a leader in the production of high quality 2-layer flexible circuit boards. Our expertise in the etching process sets us apart, ensuring our customers receive reliable and durable circuit boards suitable for their applications.

The etching process involves applying a chemical solution to a circuit board to selectively remove unwanted copper, leaving behind the desired circuit pattern. This process requires precision and attention to detail to achieve the desired circuit design.

Precision and accuracy are critical during the etching process. Any deviation from the intended circuit pattern can cause board failure and potentially cause major problems with the final product.

At Kaboer, we have perfected our etching process to ensure the highest level of precision and accuracy. Our state-of-the-art facilities and skilled technicians allow us to achieve consistent and reliable results with every etching process.

The etching process requires specific materials such as etchants, resist materials, and protective coatings to achieve the desired circuit pattern. The quality of these materials directly affects the results of the etching process.

Using high-quality equipment is critical to achieving accurate and consistent etching results. Poor quality equipment can cause changes in the etching process that can compromise the integrity of the circuit board.

Kaboer is committed to using the latest and most advanced etching technology. Our investment in cutting-edge equipment ensures that the etching process is performed with the highest level of precision and efficiency.

The etching process involves several steps, including cleaning the substrate, applying resist material, exposing circuit patterns, and etching away unwanted copper. Every step requires meticulous attention to detail to achieve the desired results.

Kaboer’s quality control is integrated into every step of the etching process. We employ rigorous inspection and testing to ensure our etched circuit boards meet the highest standards of quality and reliability.

Our commitment to excellence drives us to maintain the highest standards in all aspects of our etching process. From material selection to final inspection, we prioritize quality and precision at every stage.

The etching process can present challenges such as under-etching, over-etching, and resist adhesion issues. Addressing these challenges requires expertise and a proactive approach to ensure consistent and reliable results.

At Kaboer, we develop comprehensive solutions to solve common etching challenges. Our experienced team has the ability to identify and resolve issues to ensure the etching process runs smoothly and efficiently.

Consistency of quality is the hallmark of Kaboer’s etching process. We are committed to providing etched circuit boards that meet the highest reliability and performance standards, regardless of design complexity.

The etching process is a critical stage in 2-layer flexible circuit board manufacturing, and its importance cannot be overstated. Precision, accuracy and quality control are essential elements for reliable and durable circuit boards.

Kaboer’s unwavering commitment to quality and excellence makes us a trusted partner for customers looking for high-quality etched circuit boards. 16 years of experience have honed our expertise and made us an industry leader.

16 years of experience has allowed us to improve our processes and gain a deep understanding of the complexities of etching 2-layer flexible circuit boards. This experience sets us apart and allows us to provide our customers with quality products.

For reliable and high quality 2-layer flex circuit boards, contact Kaboer. Our team is ready to discuss your specific requirements and provide a tailor-made solution to meet your needs.

Kaboer’s expertise and commitment to quality etching processes make us the ideal partner for your circuit board needs. Trust us to deliver outstanding results that meet and exceed your expectations.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..