Flexible PCBs owe their versatility to a smart mix of materials, each playing a role in balancing flexibility, durability, and performance. These components aren’t just random choices—they’re carefully selected to let circuits bend, twist, and survive in everything from smartwatches to rocket sensors. Let’s break down the key players.

At the core is the substrate, the flexible "base" that holds everything together. Polyimide (PI) is the star here. It’s heat-resistant (withstanding up to 300°C), chemically stable, and thin enough to fold without cracking—perfect for high-stakes uses like medical implants or automotive engine bays. For simpler, lower-cost devices (think remote controls), PET (polyethylene terephthalate) steps in. It’s cheaper but less heat-tolerant, making it a budget-friendly pick for low-power gadgets.

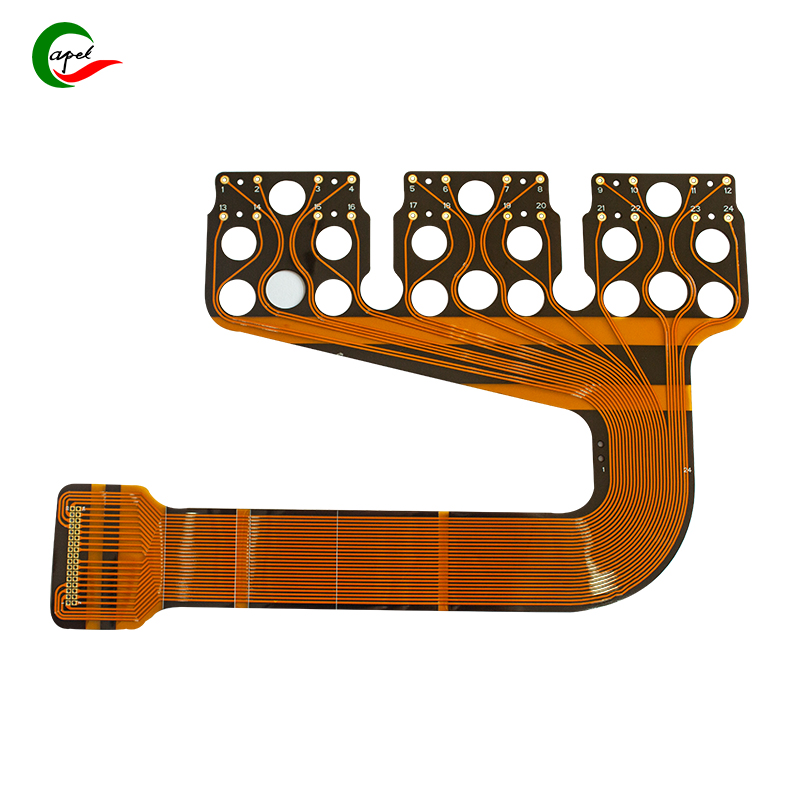

No PCB works without conductors, and flexible versions rely on copper for its unbeatable combo of conductivity and bendability. Two types dominate:

- Rolled copper: Pressed into thin sheets, it’s super flexible—ideal for foldable phones or robotic arms that bend thousands of times.

- Electrodeposited copper: Built up through chemical processes, it’s smoother and better for tiny, dense circuits like those in wireless earbuds.

In harsh environments (marine sensors, industrial gear), copper gets a boost with plating—usually gold or nickel. This adds corrosion resistance, ensuring signals flow even when exposed to salt, moisture, or chemicals.

To bond layers without killing flexibility, epoxy-based adhesives are the go-to. They’re strong enough to keep substrates and copper traces stuck but flexible enough to bend. For high-performance setups (like aerospace electronics), "adhesive-free" designs skip glue altogether, using heat and pressure to bond layers—this reduces thickness and improves heat dissipation, critical for equipment in extreme temperatures.

On top, cover layers (often made from PI or PET) act as a shield. They protect copper traces from scratches, dust, and moisture, ensuring the PCB lasts longer. Think of them as a tough, flexible "skin" for the circuit.

Small but mighty, these tweak the material mix for specific needs. Glass fibers can be added to substrates for extra strength in areas that need a little rigidity (like connector ends). Flame-retardant additives make PCBs safer for home electronics, while moisture barriers help them survive humid environments (hello, bathroom smart mirrors).

These materials work in harmony to solve a big problem: making circuits that aren’t stuck in a rigid shape. Polyimide’s flexibility lets a smartwatch wrap around your wrist; copper’s conductivity ensures your phone charges fast; adhesives keep layers from peeling when you fold your tablet. It’s this balance that makes flexible PCBs indispensable in today’s tech—proving that even the smallest material choices can enable big innovations.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.