Have you ever picked up a smartphone, smartwatch, or even a coffee maker and wondered, "What’s inside that makes it work?" Chances are, the answer lies in a printed circuit board (PCB)—and the materials that make up this PCB are the key to keeping your device running reliably day after day.

PCB materials are not random combinations of plastic and metal scraps. Each material has a specific purpose, and choosing the right ones can even determine whether a device lasts 5 years or fails in just 6 months. Below, we break down the core materials that make up a PCB and explain their importance.

The substrate acts as the "skeleton" of the PCB, holding all components in place and keeping them stable. The most mainstream substrate today is FR-4 (fiberglass-reinforced epoxy resin), and its status as an industry "workhorse" stems from three core advantages:

-

Strong yet lightweight: It has enough strength to prevent deformation while not adding extra weight to the device. This makes it ideal for portable devices like smartphones and tablets, as well as automotive electronics that require installation in tight spaces.

-

Heat-resistant: When the chips in a device heat up during operation, FR-4 can withstand temperatures up to 130°C (266°F) without melting or warping.

-

Cost-effective: It strikes a balance between performance and cost, which is why 90% of consumer electronics (such as phones and smart home appliances) use FR-4 as their substrate.

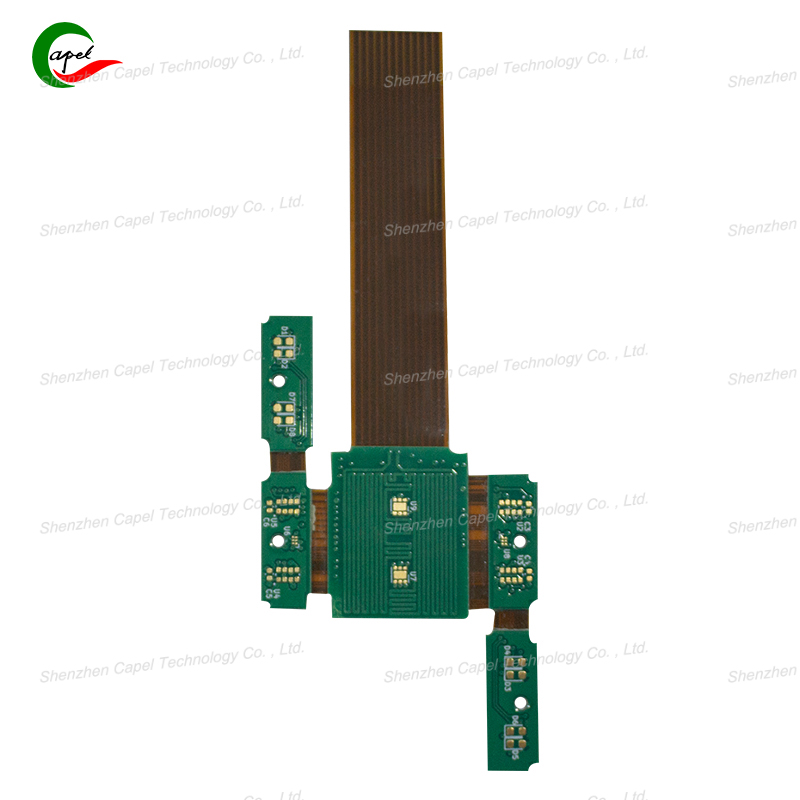

Of course, special scenarios call for specialized substrates: Flexible PCBs (like those in foldable phones) use polyimide (PI), which can be bent repeatedly without breaking; high-heat devices such as power adapters use aluminum-based substrates for better heat dissipation. However, for most everyday devices, FR-4 is more than sufficient.

If the substrate is the "skeleton," copper foil is the PCB’s "nervous system"—it transmits electrical current and signals between components like chips, LEDs, and buttons. Different scenarios require different types of copper foil:

-

Electrodeposited (ED) Copper: Typically 1 ounce thick (about the thickness of a human hair) and flexible. It is suitable for small, precision PCBs in devices like hearing aids and smartwatches, where space is extremely limited.

-

Rolled Annealed (RA) Copper: Thicker and stronger, capable of carrying high currents. It is used in high-power devices such as power banks and kitchen appliances. Even when the device vibrates (e.g., during drone flight), RA copper foil is less likely to break.

High-quality copper foil is essential for stable device operation: Poor-quality, thin copper foil can lead to slow signal transmission or even complete power failure. Many cheap devices have short lifespans precisely because they use low-quality thin copper foil, which wears out easily during use.

After the copper foil and components are installed, the PCB needs a "shield" to resist external interference—this is where the solder mask and silkscreen come in:

-

Solder Mask: A thin coating (commonly green, but also black or blue) that covers the copper foil. Its core role is to prevent short circuits (avoiding accidental contact between two copper traces) while blocking dust, moisture, and scratches. For example, if your phone accidentally gets splashed with water but still works, you have the solder mask to thank.

-

Silkscreen: The small white text and symbols on the PCB (such as "R1" next to a resistor or "GND" for ground). It is not just for decoration; it serves as a "guide" for engineers and technicians—without these marks, assembling and repairing a PCB would be like putting together a puzzle without labels, significantly reducing efficiency.

Flexible PCBs (like those in foldable phones and wearable devices) require one additional key material: adhesives. Their role is to firmly bond copper foil to the flexible substrate (usually polyimide). High-quality adhesives remain stable even after thousands of bends, while low-quality ones easily peel off, directly causing PCB failure. This is a major reason why some cheap foldable phones develop faults after a few months of use.

You may never disassemble a device to look at its PCB, but the materials used directly affect the device’s feel, lifespan, and performance:

-

A phone with a high-quality FR-4 substrate and RA copper foil will be more durable than one with a cheap plastic substrate and thin copper foil.

-

A smartwatch with a sturdy solder mask and clear silkscreen is less likely to short-circuit if splashed with water, while a low-cost model may fail immediately upon contact with water.

Next time you buy an electronic device, remember: A good device relies not just on fancy features, but also on high-quality PCB materials. These "invisible details" are the true determinants of device quality.

Related Link: