If you’ve used devices that bend, twist, or fit into uniquely shaped spaces—like the slim body of wireless earbuds, the curved band of a fitness tracker, or even the rotating camera gimbal of a drone—there’s a good chance they contain a key component: the rigid-flex PCB. It solves the problem of rigid PCBs being "too stiff to fit into irregular spaces" and 弥补 the flaw of flexible PCBs being "unable to support heavy components". Below, we’ll break down this "all-around circuit board" from its definition, working principle, advantages to real-world applications.

A rigid-flex PCB isn’t a simple combination of "rigid board + flexible board"—it’s an integrated single circuit board that combines two core sections, each with a clear role:

-

Rigid Sections: Made of FR-4, the same material used in standard PCBs, they are rigid and stable—like the "load-bearing base" of the circuit board. They’re designed to hold heavy, "bend-sensitive" components such as chips, batteries, and connectors, ensuring these parts stay in place and undamaged during device operation.

-

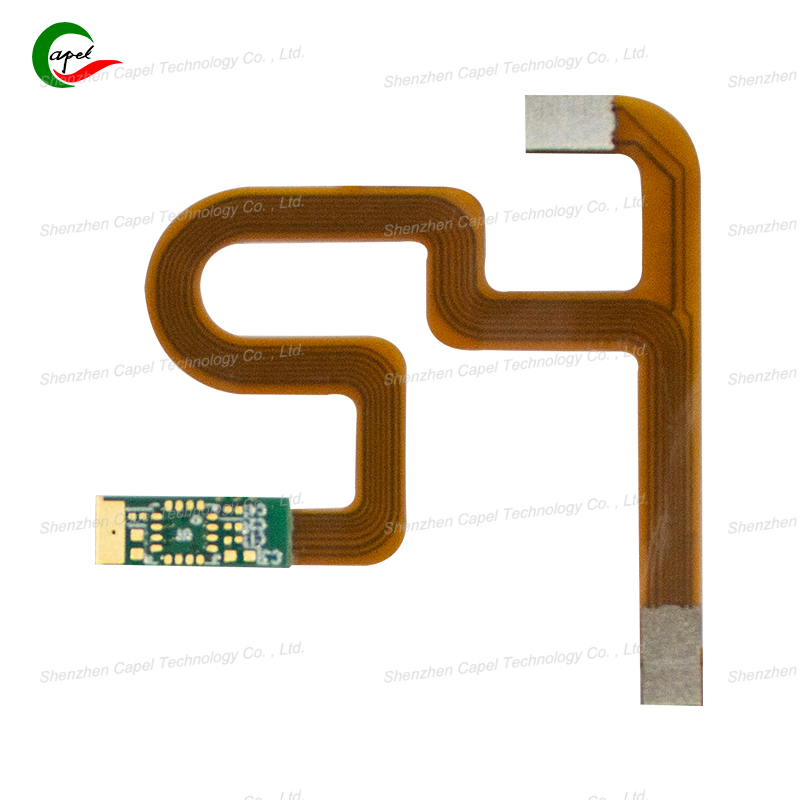

Flexible Sections: Constructed from polyimide (PI), a thin and tough material that can be folded, twisted, or bent into arcs repeatedly. Acting like "flexible bridges" connecting the rigid sections, they allow the circuit board to "shape-shift" according to the device’s form, easily fitting into narrow gaps or curved casings.

Most importantly, unlike separate rigid and flexible boards (which require messy wires for connection—wires that break easily and take up extra space), a rigid-flex PCB is a seamless single unit. All signal transmission happens internally, making it both neat and reliable.

The logic behind it is actually simple—at its core, it’s about "putting the right material in the right place":

-

Material Division of Labor: The polyimide in flexible sections is usually only 0.1–0.2mm thick, making it flexible enough to bend while still stably transmitting electrical signals. The FR-4 in rigid sections provides sufficient support, preventing components like chips and batteries from being damaged by vibration or pressure.

-

Integrated Manufacturing: During production, the rigid and flexible sections are layered and bonded together, with copper foil traces (the "nerves" of the circuit board) running through both. This allows electrical signals to flow smoothly from rigid sections to flexible sections—no extra wires needed.

A straightforward example: The hinge of a foldable phone is where rigid-flex PCBs "shine". The rigid sections in the top and bottom halves of the phone hold the screen driver chip and battery, respectively. The flexible section runs along the hinge, allowing the phone to fold thousands of times without breaking the circuit—this is how "foldable yet unbreakable" phones become a reality.

The advantages of rigid-flex PCBs all stem from "solving real pain points". For irregularly shaped and portable devices, they’re a "must-have upgrade":

-

Better Adaptability: Standard rigid PCBs are "flat and rigid"—they can’t fit into the curved dial of a smartwatch or the slim body of wireless earbuds. Rigid-flex PCBs, however, can "follow the device’s shape"; folding or bending won’t affect their functionality, giving device designers more freedom.

-

Higher Durability: Many flexible devices fail due to "connecting wires". Separate rigid and flexible boards rely on wires for connection, and these wires easily break after repeated bending. Rigid-flex PCBs have no external wires, significantly reducing failure rates—some models can even withstand over 10,000 bends.

-

Thinner, Lighter, and Space-Saving: Integrating "rigid board + flexible board + wires" into a single unit reduces volume and weight by approximately 30%. Take fitness trackers, for example: With a rigid-flex PCB, the band can be made thinner and more wrist-friendly, so you barely notice it’s there when wearing it.

Don’t think of them as "high-tech and distant"—many devices you use regularly contain rigid-flex PCBs:

-

Foldable Electronics: The hinges of foldable phones and tablets use flexible sections to enable "folding without breaking", while rigid sections hold core components.

-

Wearables: The curved bodies of smartwatches and fitness trackers, and the compact size of hearing aids, all depend on the "shape-shifting ability" of rigid-flex PCBs.

-

Medical Devices: Portable glucose monitors and heart rate monitors need to be lightweight and durable. Rigid-flex PCBs meet their size requirements while withstanding minor impacts during daily use.

-

Drones: The camera gimbal needs to rotate 360°. Flexible sections follow the gimbal’s movement, avoiding wire tangling or breaking and ensuring stable camera footage.

Rigid-flex PCBs are like "all-around stars" among circuit boards—they have the "stability" of rigid PCBs (to support heavy components) and the "flexibility" of flexible PCBs (to adapt to irregular spaces). Thanks to them, our devices can be made smaller, thinner, and more powerful.

Next time you fold your phone or adjust your smartwatch band, take a moment to think: The "flexible yet sturdy" rigid-flex PCB behind the scenes is the "invisible hero" that makes these smooth experiences possible.

Related Link: