Date: 2026-01-16

When you search for "blank pcb," you're likely at the starting point of a project. You have a circuit design ready and need to find the right circuit board as your foundation. Or perhaps you're looking for a more reliable bare board supplier for an existing product, only to find the market overwhelming—huge price variations, inconsistent quality, and communication challenges that vary wildly.

Let's get one thing straight: finding the right blank PCB supplier isn't about simple price comparison. It's about establishing a partnership. This guide will help you avoid common pitfalls and find truly reliable partners.

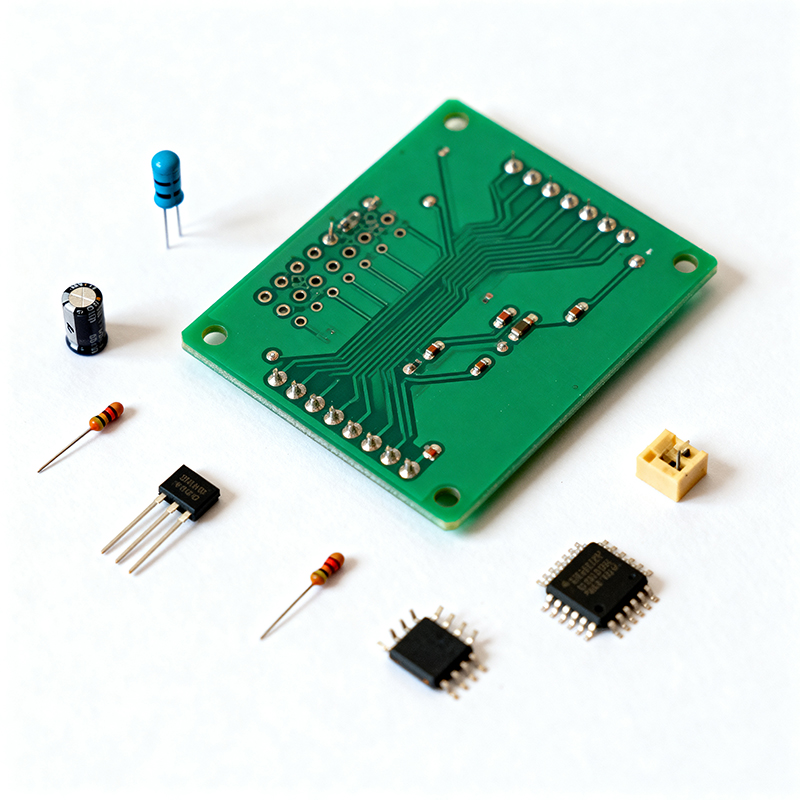

Simply put, a blank PCB is a circuit board that has completed all manufacturing processes but hasn't had any components installed yet. Think of it like a wall before painting—all the electrical conduits are in place, but switches, outlets, and lights haven't been installed yet.

In the industry, terms like "blank PCB," "bare board," and "printed circuit board" are often used interchangeably, but they all refer to the same thing: a substrate with etched circuit patterns, drilled holes, surface finish applied, ready for the assembly stage.

What happens after you send your Gerber files to a manufacturer?

Good manufacturers carefully review your design files, not just produce them blindly. They check:

Whether trace widths and spacings match their process capabilities

If pad designs are suitable for soldering (especially fine-pitch components)

If layer alignment marks are sufficiently precise

Any design details that might cause production issues

A real case: We once found a client's design had several vias too close to the board edge, which could cause hole wall damage during subsequent cutting. Informing the client to adjust the design early prevented an entire batch from being scrapped.

Different material choices directly affect final performance and cost:

Substrate: Standard FR-4 vs high-frequency materials vs high-Tg materials

Copper foil: 1oz (35μm) vs 2oz (70μm) vs thicker copper layers

Solder mask: Color, thickness, heat resistance differences

Surface finish: HASL, ENIG, immersion silver, OSP—each has pros and cons

Two main methods:

Traditional dry film process: Suitable for most conventional designs

Direct laser imaging: Higher precision, better for fine traces, but more expensive

Selection advice: If your minimum trace width is >0.15mm, both processes work; if <0.1mm, confirm if the supplier has laser imaging capability.

These tiny holes (some finer than a human hair) need precise machining, with sufficient copper deposited on the hole walls to ensure reliable electrical connections. The quality of this step often determines multilayer board long-term reliability.

Different applications need different surface finishes:

| Finish Type | Advantages | Disadvantages | Best For |

|---|---|---|---|

| HASL | Lowest cost | Poor flatness | Regular consumer electronics |

| ENIG | Flat surface, good solderability | Higher cost | Fine-pitch components |

| Immersion Silver | Good high-frequency performance | Prone to oxidation | RF circuits |

| OSP | Eco-friendly, low cost | Limited shelf life | High-volume fast production |

Professional manufacturers don't skip this step:

Electrical testing: Ensures no opens or shorts

Optical inspection: Checks for visual defects

Dimensional measurement: Confirms compliance with design specs

Reliability sampling: Like thermal stress testing

When you receive samples, check with the naked eye and magnifier:

Solder mask: Even, no bubbles, no peeling

Silkscreen markings: Clear, no misalignment

Pads: Flat, no oxidation

Board edges: Smooth, no burrs

Hole walls: Clean, no residue

Use calipers to measure:

Whether board thickness meets requirements

If outline dimensions are accurate

If hole positions match the design

Simple multimeter tests can check:

If adjacent pads are shorted

If lines that should connect are continuous

If insulation resistance is sufficient

When different suppliers give quotes varying by 30% or more for the same design, differences typically come from:

Substrate brand and quality grade

Copper foil thickness and type

Ink and chemical quality

Surface finish material costs

Trace width/clearance requirements (0.2mm vs 0.1mm)

Minimum hole size (0.3mm vs 0.1mm)

Number of layers (4-layer vs 12-layer)

Special process needs (impedance control, blind/buried vias, etc.)

Test coverage (sampling vs 100% testing)

IPC standard class followed (Class 1, 2, or 3)

Whether complete test reports are provided

Factory automation level

Geographic location and logistics costs

Order quantity and production scheduling flexibility

Actually, abnormally low prices often mean:

Using substandard or recycled materials

Reducing necessary testing steps

Non-compliant process parameters

No quality guarantee

Different manufacturers' FR-4 grades can have significant performance differences:

Different dielectric constant stability

Different thermal expansion coefficients

Different moisture absorption rates

Different long-term reliability

Changing PCB suppliers often requires revalidation, potentially involving:

New process parameter adjustments

Different material characteristics

Re-doing reliability testing

To get accurate quotes from suppliers, provide:

Complete design files: Gerber files, drill files, stack-up structure

Clear specification requirements: Materials, board thickness, copper weight, surface finish, special processes

Quantity and timing requirements: Estimated annual usage, desired lead time

Your biggest concerns: Like "We're particularly concerned about impedance control accuracy"

Technical capability:

"Our design has 0.1mm trace width—what's your actual yield?"

"How do you ensure layer-to-layer alignment accuracy for multilayer boards?"

"Do you provide free DFM analysis?"

Quality control:

"Do you provide first-article reports and test reports for every batch?"

"What's your handling process when quality issues are found?"

"Is client visitation to the production floor possible?"

Communication and service:

"What's the standard lead time from file confirmation to shipment?"

"How do you communicate with us if issues are found during design review?"

"Do you have dedicated technical support teams?"

Running a PCBA factory in Shenzhen over the years, we've seen various blank PCB application scenarios:

Practical experience with material selection:

Even "standard FR-4" has different choices. For industrial equipment working in harsh environments, we recommend mid-Tg or high-Tg materials. Though costs increase 10-15%, reliability improves significantly. One client reduced product failure rates in high-temperature environments by 70% after switching to high-Tg material.

Design optimization suggestions:

Often, small design adjustments can significantly reduce costs. We helped a client adjust non-critical signal trace widths from 0.15mm to 0.2mm. Though only a few parameters changed, yield improved from 85% to 97%, and overall costs actually decreased.

Thoughts on testing strategy:

For critical applications, 100% electrical testing is a worthwhile investment. A medical device client initially chose sampling inspection to "save costs," only to have defective boards reach assembly, where rework costs were 8 times the testing expense. They eventually switched to 100% testing, and total costs actually decreased.

Observations on supplier cooperation:

The most successful long-term collaborations are often with clients willing to communicate early. They seek our manufacturing advice during the design phase, avoiding subsequent redesigns and delays. This cooperation model typically brings better overall benefits than constantly searching for the "lowest quote."

Try this simple evaluation table:

| Evaluation Criteria | Weight | Supplier A | Supplier B | Supplier C |

|---|---|---|---|---|

| Technical match | 30% | |||

| Price reasonableness | 25% | |||

| Communication quality | 20% | |||

| Past case studies | 15% | |||

| Geographic location | 10% |

Score each supplier (e.g., 1-5 points), multiply by weight. The highest total score usually indicates the most balanced choice.

Clarify priorities: Cost, quality, lead time—which matters most to you?

Involve suppliers early: Consult on manufacturability during design phase

Start with small batches: Place small orders first to verify quality and stability

Establish clear standards: Define your quality requirements and acceptance criteria

Consider backup suppliers: Mitigate supply chain risks

Choosing a blank PCB supplier isn't a one-time transaction—it's the beginning of a long-term partnership. A good supplier doesn't just manufacture circuit boards; they become part of your product's success—their professional advice can help you optimize designs, improve yields, and reduce costs.

Whether you're purchasing for the first time or are an experienced buyer, remember three things: clear communication, reasonable expectations, and mutual understanding. These bring more lasting success than simply pursuing the lowest price.

If you're evaluating suppliers or have specific technical questions, we're always willing to share our experience. After all, in this industry, good information sharing helps everyone move further together.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..