Date: 2025-12-25

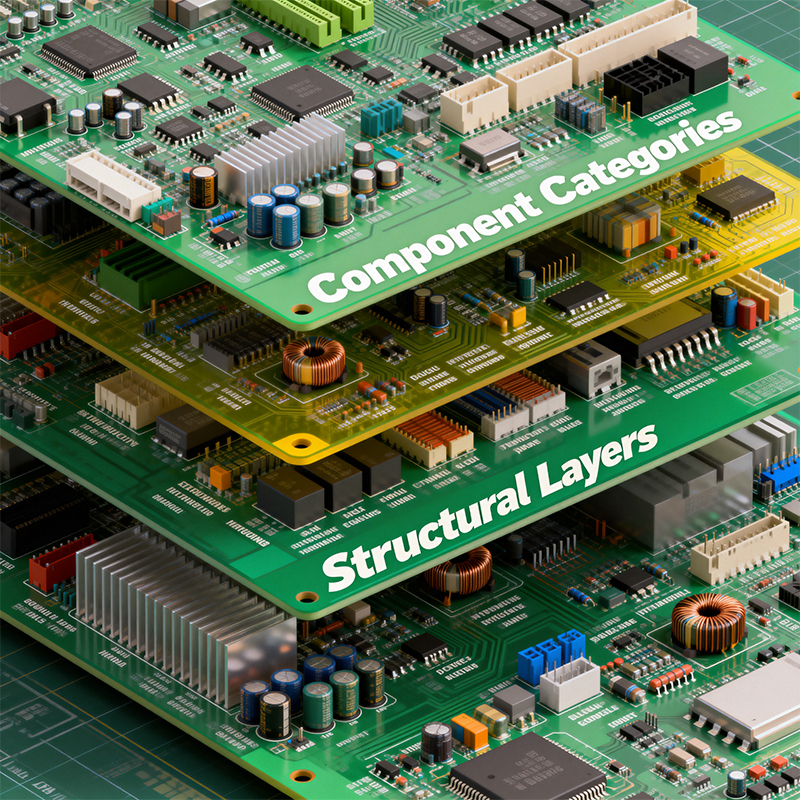

Circuit Card Assembly (CCA) is the complete process of mounting, soldering, and integrating electronic components onto a printed circuit board (PCB) to create a functional, ready-to-use electronic module. Essentially, it is synonymous with PCB Assembly (PCBA). The term “CCA” emphasizes the final assembled unit as a complete, functional “card” or sub-assembly, often associated with applications demanding high reliability, traceability, and rigorous testing, commonly found in industrial automation, automotive, medical devices, and telecommunications infrastructure.

For a manufacturer, understanding CCA is critical—it represents the transformative step where your design transitions from a bare board into a tested, operational component of a larger system.

While often used synonymously, subtle distinctions exist in industry usage:

CCA (Circuit Card Assembly): Emphasizes the complete, assembled unit as a functional “card” or sub-assembly. It often implies a focus on robustness, full testing, and readiness for integration into a larger system.

PCBA (Printed Circuit Board Assembly): The most universal term, focusing on the process of assembling the board. Used broadly across consumer, industrial, and commercial sectors.

PCA (Printed Circuit Assembly): Another common variant, identical in meaning to PCBA.

In practice: Bare PCB + Components + Assembly Process = CCA/PCBA/PCA.

A professional CCA process is a controlled sequence of interdependent stages, with a strong emphasis on verification:

Preparation & Kitting: The bare PCB is prepared, and all electronic components are sourced, verified, and kitted per the Bill of Materials (BOM).

Solder Paste Application (for SMT): For Surface Mount Technology (SMT) components, solder paste is precisely printed onto the board’s pads using a stencil.

Automated Component Placement: High-speed pick-and-place machines accurately position SMT components. Through-hole (THT) components may be inserted automatically or manually.

Soldering:

Reflow Soldering: For SMT components, the board passes through a reflow oven to form permanent solder joints.

Wave or Selective Soldering: For THT components, the board’s underside is exposed to a solder wave, or solder is applied selectively.

Cleaning & Coating: Flux residues are removed. A conformal coating (acrylic, silicone, urethane) is often applied for protection against moisture, dust, chemicals, and thermal stress—a key feature for CCAs destined for challenging environments.

Comprehensive Inspection & Testing: This is a defining characteristic of a robust CCA process. It typically includes:

Automated Optical Inspection (AOI): For detecting solder joint and component placement defects.

X-Ray Inspection: For examining hidden solder joints (e.g., under BGAs).

In-Circuit Test (ICT): Checks individual component values, polarity, and connections.

Functional Test (FCT): Powers up the assembly in a simulated or actual operating environment to validate full system performance against specifications.

Final Packaging & Traceability: The finished CCA is packaged to prevent ESD and physical damage. Serial numbers and lot codes are applied for full traceability back to materials and production data.

CCA is the preferred term in sectors where failure is not an option and long-term reliability is paramount. Common applications include:

Industrial Control Systems: PLCs, motor drives, robotics, and automation equipment.

Medical Electronics: Diagnostic imaging, patient monitoring, and therapeutic devices.

Automotive Electronics: Engine control units (ECUs), advanced driver-assistance systems (ADAS), and battery management systems (BMS) for electric vehicles.

Telecommunications & Networking: Base station hardware, network routers, and data center infrastructure.

Energy & Infrastructure: Power conversion systems, smart grid controls, and renewable energy inverters.

Selecting the right partner is a strategic decision for high-reliability products. Look for a provider with:

Certified Process Control: Certifications like ISO 9001 and IATF 16949 (Automotive) demonstrate a commitment to quality management systems.

IPC Standards Expertise: Mastery of IPC-A-610 (Acceptability of Electronic Assemblies) for defining workmanship quality, particularly for Class 2 (dedicated service) and Class 3 (high-performance) products.

Advanced Testing Arsenal: In-house capability for AOI, X-Ray, ICT, and FCT is crucial, not just outsourcing.

Supply Chain & Component Management: Expertise in sourcing and handling components, including managing long-lifecycle and obsolete parts for industrial products.

Full Engineering Support: Proactive Design for Manufacturability (DFM) and Testability (DFT) analysis to prevent issues before production begins.

Q1: What is the difference between a CCA and a PCB?

A: A PCB (Printed Circuit Board) is the bare, unpopulated board with copper traces. A CCA (Circuit Card Assembly) is the final, functional product after all electronic components have been assembled and soldered onto that PCB.

Q2: What does “Class 3” CCA mean?

A: “Class 3” refers to the IPC-A-610 acceptability standard for electronic assemblies. Class 3 defines the most stringent criteria for workmanship and is required for products where continued high performance or performance-on-demand is critical, such as in life-support medical devices or critical infrastructure systems.

Q3: Is conformal coating always necessary on a CCA?

A: No, but it is highly recommended for any product exposed to harsh environments (moisture, dust, chemicals, wide temperature swings). It dramatically improves long-term reliability and is a standard requirement for many industrial, automotive, and outdoor applications.

Q4: What files are needed for a CCA quote?

A: You will typically need:

Gerber Files (for PCB fabrication)

Complete BOM with Manufacturer Part Numbers (MPNs)

Assembly Drawings (with coating, testing, and special instructions)

Schematic (for test development)

Pick-and-Place File (for SMT programming)

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..