Date: 2025-11-06

Let me break down how double-sided flex boards are actually built. Think of them as a flexible sandwich with copper on both sides.

The Main Ingredients (What Every Board Has)

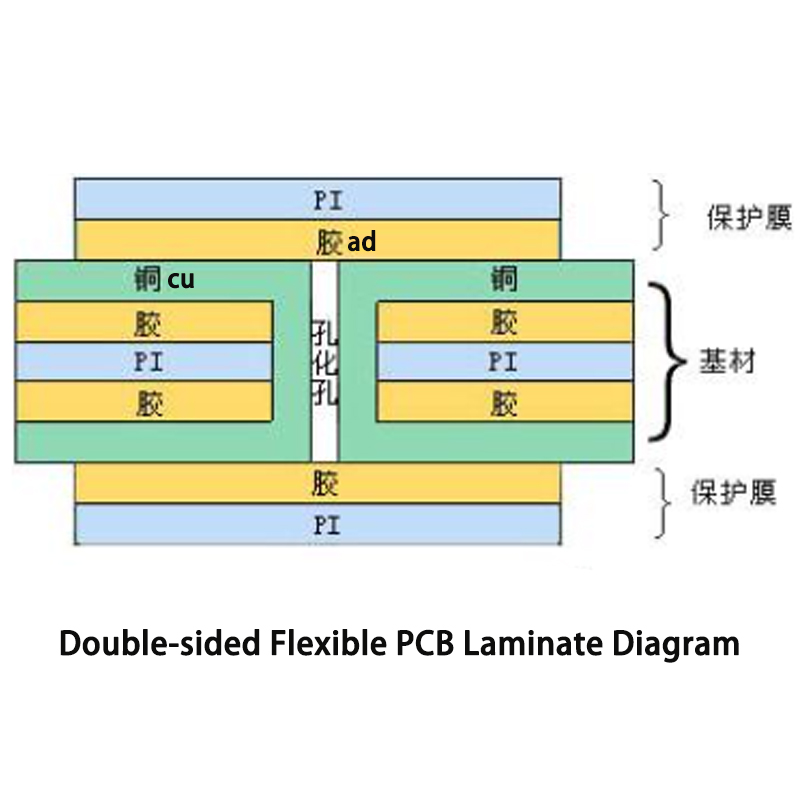

At the center is the flexible base material - usually polyimide (what we call PI) or sometimes polyester (PET). PI is the tough stuff that can handle soldering heat, while PET is cheaper but can't take high temperatures. This layer is thin - about as thick as a couple pieces of paper.

Next comes the glue that holds everything together. We use special flexible adhesives that can bend without cracking. This stuff is really thin - barely noticeable but absolutely essential.

Then we have the copper layers - one on each side. We typically use either electrodeposited copper (cheaper) or rolled copper (more flexible for boards that bend constantly). The copper is thinner than what you'd find on rigid boards.

Covering everything are the protective layers. These are like flexible plastic sheets that keep the copper safe from damage and moisture. They're transparent to let you see the circuits underneath.

The magic happens with the plated through holes. We drill tiny holes through the entire stack and plate them with copper to connect both sides. It's like having little copper tunnels running between the two sides.

Optional Add-Ons (When You Need Extra Features)

Sometimes we add stiffeners - little rigid pieces near connectors or components that need extra support. These are like putting knee pads on flexible pants - protection where you need it, flexibility everywhere else.

We can also add solder mask (that green coating you see on many boards) and silkscreen labels to show where components go.

For boards that need to handle electrical noise, we might add shielding layers. These are like Faraday cages built into the board to protect sensitive signals.

How It All Stacks Up

If we look at a cross-section, from top to bottom you'd see:

Protective cover

Glue

Top copper layer

Glue

Flexible base material

Glue

Bottom copper layer

Glue

Protective cover

And those little copper-plated holes connecting everything vertically.

What Makes These Boards Special

You get twice the wiring space of single-layer boards without going full multi-layer. The total thickness is usually under half a millimeter, so they stay flexible. They can bend pretty tightly - we're talking radii as small as 3-5mm for most applications.

Since there are no internal layers or fancy buried vias, they're easier to make than multi-layer boards. That means better yields and lower costs.

Practical Stuff to Remember

Choose rolled copper if your board will be bending constantly. It costs more but lasts much longer.

The adhesive type matters more than people realize. Cheap adhesive can crack after repeated bending.

Stiffener placement is an art. Put them in the wrong spots and you create stress points that can cause failures.

These boards hit the sweet spot between simple single-layer and complex multi-layer designs. They give you decent complexity without breaking the bank, which is why you'll find them in everything from consumer electronics to medical devices.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..