Date: 2025-11-06

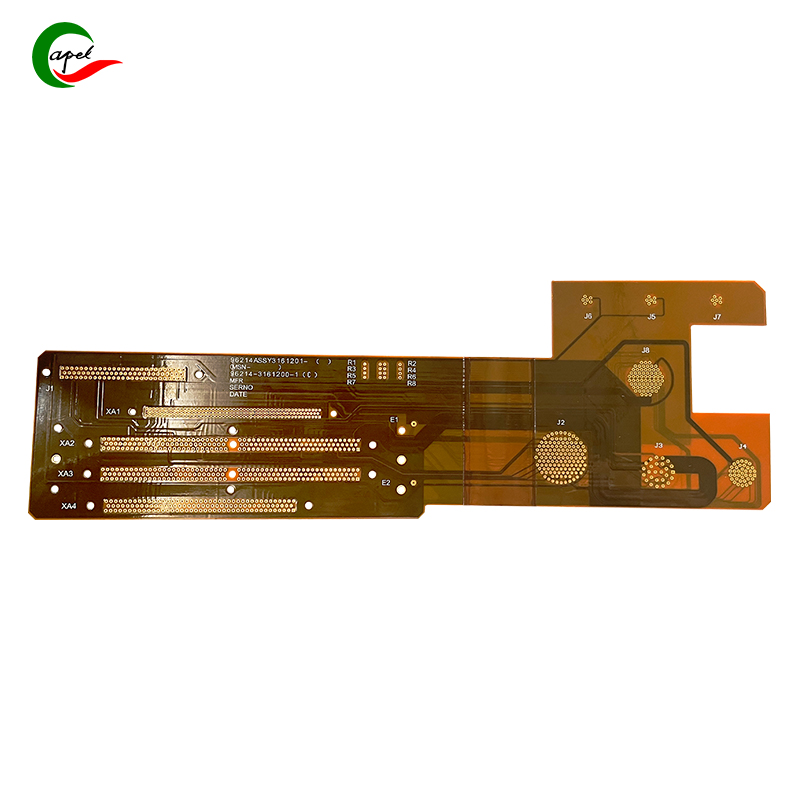

Let's talk about multi-layer flex circuits. These are the fancy, expensive cousins of regular flex boards. Think of them like a club sandwich - multiple layers stacked together, each with its own purpose.

Why People Use These Things

The main reason? You can pack way more circuitry into the same space. Instead of just having circuits on one or two layers, you've got four, six, even eight layers of copper traces. It's like having a multi-story parking garage instead of a single-level lot.

They're also great for keeping signals clean. You can dedicate entire layers to power or ground, which helps prevent interference between different circuits. If you're working with high-speed data or sensitive analog signals, this is pretty much essential.

Another plus - they're tough. The inner layers are protected from the outside world, so they're less likely to get damaged by bending or environmental factors.

The Downside - And It's a Big One

These boards cost an arm and a leg. We're talking three to five times more expensive than simple flex boards. The materials cost more, the equipment to make them costs more, and you need highly skilled people to run everything.

They're also stiffer. Each additional layer makes the board less flexible. While they can still bend, you can't fold them up like you could with a simple single-layer flex circuit.

Manufacturing is a pain too. Getting all those layers to line up perfectly is like trying to stack ten pieces of paper and have all the edges match exactly. It's tough, and the failure rate is higher than with simpler boards.

If something goes wrong inside the board? Good luck fixing it. Usually, you just have to throw the whole thing out and start over.

When You Actually Need One

You'd use these in situations where cost isn't the main concern and you need maximum performance in a small, flexible package. Think:

Military gear

Medical implants

High-end smartphones

Aerospace equipment

Serious industrial applications

For most everyday applications, they're overkill. But when you really need them, there's no substitute.

Basically, multi-layer flex is that expensive tool you only pull out when the job absolutely requires it. For everything else, you're better off with something simpler and cheaper.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..