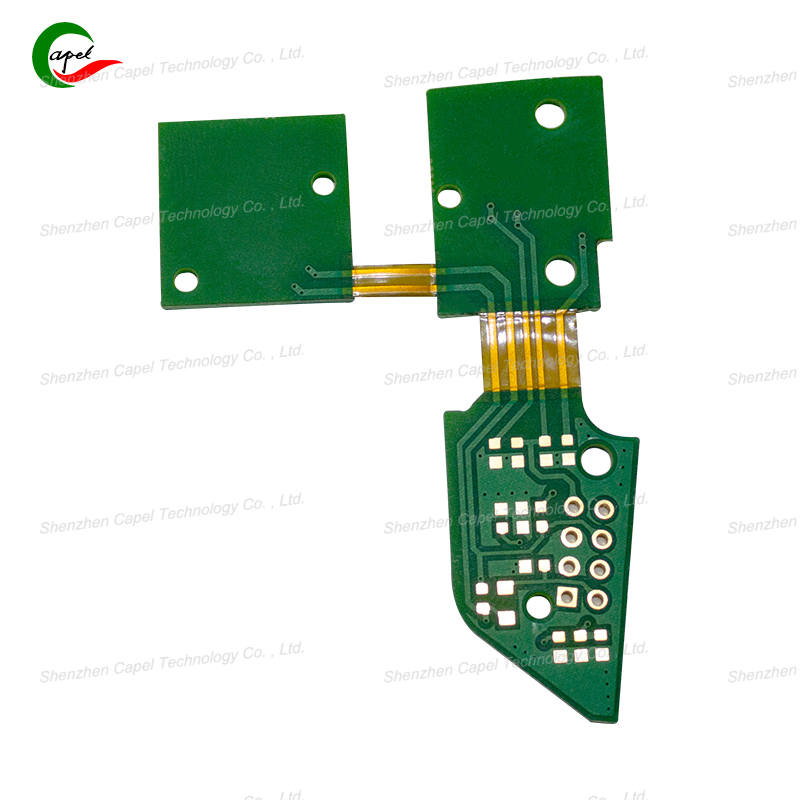

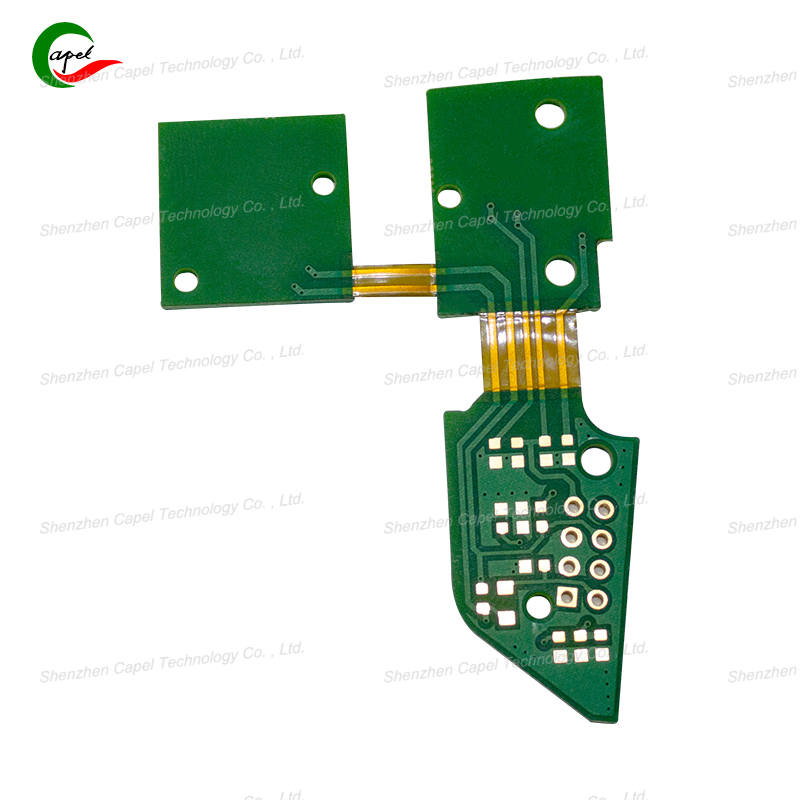

Drone Rigid-Flex PCBs: Vibration Resistance & Lightweight Design

Date: 2025-09-17

Drones live a bumpy life—their motors hum at high speeds, they hit gusts of wind, and they sometimes land harder than planned. The rigid-flex PCBs inside them have two big jobs: keep the flight controller, cameras, and sensors connected while being light enough to avoid draining the battery. A heavy PCB shortens flight time; a flimsy one breaks from vibration.

The solution? Rigid-flex PCBs engineered to balance "tough against shakes" and "light enough to fly." Below’s a simple breakdown of how to design them, why both traits matter for drones, and the key tweaks that make all the difference.

Ordinary PCBs (rigid or flexible alone) fail here. Drones have unique stressors:

-

Nonstop vibration: Motors spin 10,000+ RPM, sending shakes through every component. Loose traces or weak bonds crack quickly.

-

Flight time depends on weight: Every extra gram of PCB means less time in the air—critical for drones used for photography or inspections.

-

Tight space: PCBs fit in narrow arms or bodies, so they need to bend around components without adding bulk.

Lightness starts with smart material and layout choices—no need for heavy components or excess layers:

Toughness isn’t about being heavy—it’s about reinforcing weak spots and using stable materials:

-

Reinforce flex-rigid transitions

The spot where flexible PI meets rigid FR-4 is a vibration weak point. Extend the PI coverlay 2mm onto the FR-4 and add a thin epoxy adhesive layer—this bonds them tight so they don’t separate.

-

Use vibration-resistant adhesive

Ditch acrylic glue (it softens and loosens from shakes). Opt for high-temp epoxy adhesive—it stays rigid but flexible, absorbing vibration without breaking the bond between layers.

-

Secure components low and tight

Mount heavy parts (like flight controllers) on the rigid FR-4 section, not the flexible PI. Use low-profile surface-mount components (no bulky through-hole parts) and glue them with extra solder—this stops them from rattling loose.

These small tweaks boost performance without adding weight:

-

Add tiny stiffeners (not heavy ones)

Glue 0.5mm thin FR-4 stiffeners to flexible sections that connect to motors (the shakiest parts). They add strength but only 0.1–0.2 grams.

-

Route traces away from vibration hotspots

Keep signal traces (for GPS/camera) at least 1mm away from power traces (for motors)—motor vibration can disrupt sensitive signals if they’re too close.

-

Avoid over-coating

Skip thick conformal coating (it adds weight). Use a thin 10μm silicone coat only on high-vibration areas (like motor connections)—enough protection, no extra bulk.

A rigid-flex PCB that’s both light and vibration-resistant changes how a drone performs:

-

Longer flight time: A 5-gram lighter PCB adds 5–10 minutes of flight—game-changing for inspections or aerial shots.

-

No mid-flight glitches: Vibration-resistant traces and bonds mean GPS stays locked, cameras don’t blur, and motors respond smoothly.

-

Durability: It survives hard landings or windy days without breaking—less downtime for repairs.

For drones, there’s no trade-off between lightness and toughness—rigid-flex PCBs make both possible. By leaning into thin, strong materials, trimming excess weight, and reinforcing against vibration, you get a board that doesn’t just fit in the drone—it makes the drone better.

Every gram saved and every shake absorbed translates to more time in the air, sharper footage, and fewer trips back to the workbench. When it comes to drone performance, the rigid-flex PCB isn’t just a component—it’s the quiet enabler of every smooth flight and successful mission.

related link: