Rigid-Flex PCB Repair: Quick Fault Diagnosis

Date: 2025-09-17

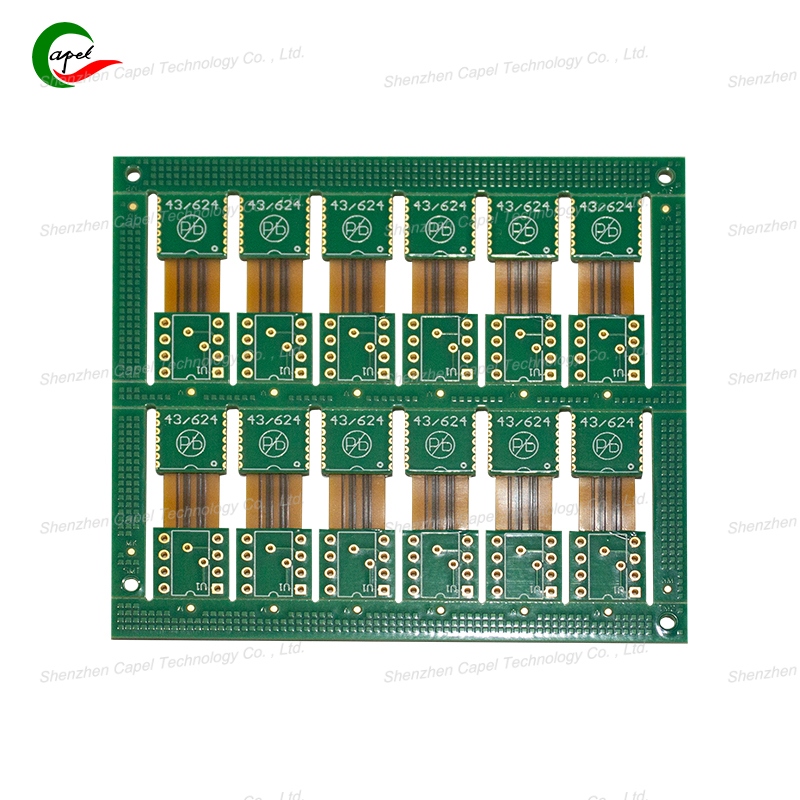

Rigid-flex PCBs are tricky when they break. Unlike regular rigid PCBs (which sit still) or flexible FPCs (which bend but have no stiff parts), rigid-flex boards mix two worlds—so their faults hide in the space between "stiff and steady" and "bendable and fragile." A glitch could be a cracked trace in the flexible section, a loose bond between layers, or a damaged component on the rigid part.

The good news? You don’t need fancy tools to find most problems. Below’s a step-by-step guide to quick fault 排查 (diagnosis) for rigid-flex PCBs—simple enough for anyone with basic electronics sense, and focused on the issues that pop up most often.

Before touching the PCB, do two things:

-

Disconnect power: Even small batteries can short circuits or shock you—unplug everything first.

-

Grab basic tools: A bright flashlight, a magnifying glass (10x works), a multimeter (for checking signals/power), and a soft brush (to wipe dust). No need for expensive scanners—most faults are visible or testable with these.

Most rigid-flex problems leave clues you can see. Start here—you’ll catch 60% of issues in 5 minutes:

-

Look at the flex-rigid transition: This is the #1 failure spot. Check for cracks in the polyimide (PI) flexible layer, or gaps where the rigid FR-4 meets PI (signs of delamination). If the coverlay (protective film) is peeling, moisture or dust might have damaged traces underneath.

-

Inspect the flexible section: Bend it gently (don’t force!) and watch for tiny cracks in the copper traces (they look like thin white lines). Also check for "kinks"—sharp bends that break traces inside.

-

Check rigid components: On the FR-4 part, look for burnt components (discolored plastic, melted solder) or loose parts (they’ll rattle if you tap the PCB lightly). Solder joints should be smooth and shiny—dull or cracked joints mean poor connection.

If the visual check shows nothing, use a multimeter to test two key things:

-

Power check: Connect the multimeter to the PCB’s power pins (look for "VCC" or "+" labels). Turn on the device—if there’s no voltage (or it’s lower than it should be), the problem is power-related:

-

Check the flexible power traces (they carry battery/charger power) for breaks.

-

Test the bond between rigid and flexible layers—delamination can cut power flow.

-

Signal check: For devices with screens or sensors (e.g., a drone’s camera), test signal traces. Touch one multimeter probe to the sensor pin (on the flexible section) and the other to the chip pin (on the rigid section). No signal means a broken trace or bad connection.

Certain problems happen over and over with rigid-flex PCBs. Here’s how to spot the most frequent ones:

-

Delamination (layers coming apart):

How to spot: Bubbles or gaps between PI and FR-4, or a "spongy" feel when pressing the transition area.

Why it happens: Too much heat (from soldering) or moisture seeping in.

-

Broken flex traces:

How to spot: Cracks in copper (visible with a magnifying glass) or no signal/power through the flexible section.

Why it happens: Too many bends or a sharp impact (like dropping the device).

-

Loose rigid components:

How to spot: Components that wiggle, or solder joints that look cracked.

Why it happens: Vibration (e.g., in a robot or drone) or poor soldering.

Quick diagnosis also means knowing your limits:

-

Fixable: Small cracks in traces (can be repaired with conductive ink), loose solder joints (re-solder them), or peeling coverlay (seal with epoxy).

-

Not fixable: Severe delamination (layers are too separated), multiple broken traces, or burnt chips (replace the PCB instead—repair will cost more time than it’s worth).

Rigid-flex PCB repair starts with finding the problem fast—and that’s all about focusing on the board’s unique mix of rigid and flexible parts. Start with a visual check (transition area first!), then test power and signals. Most faults hide in plain sight or show up with a simple multimeter test.

The key isn’t to become an expert—it’s to avoid guessing. By following these steps, you’ll either fix the PCB quickly or know when it’s time to replace it. For rigid-flex boards, speed and focus beat fancy tools every time.

related link: