Date: 2026-01-07

Chances are you've noticed it: your team is spending more and more time firefighting production line issues, chasing component deliveries, and handling quality headaches. The path from a great design to a reliable, mass-produced product seems to be getting bumpier, even when the design itself is solid.

That’s when many teams start looking into EMS – Electronic Manufacturing Services. Think of it as handing off the entire manufacturing operation to an external, specialized team. You remain the brain and soul of the product—defining it, designing it, bringing it to market. Your EMS partner acts as your manufacturing arm, making sure your vision is translated accurately into physical reality.

A good EMS partner’s scope typically covers most steps that come after you finalize your design:

From Design Files to Production-Ready Plans

Often, a design is perfect on screen but runs into unexpected problems on the factory floor. For instance, a certain chip package might have a notoriously low yield during SMT placement, or a component layout could make testing difficult later. An experienced EMS team can spot these potential issues during the design review phase, suggesting adjustments to avoid costly delays and rework down the line.

Taming the Supply Chain Beast

Managing the procurement of hundreds of components, dealing with sudden shortages, price hikes, or quality issues—it’s a full-time job in itself. EMS firms leverage their scale and long-term supplier relationships to manage the supply chain more predictably. They know which parts are reliable and which are problematic, saving you significant hidden costs and mental energy.

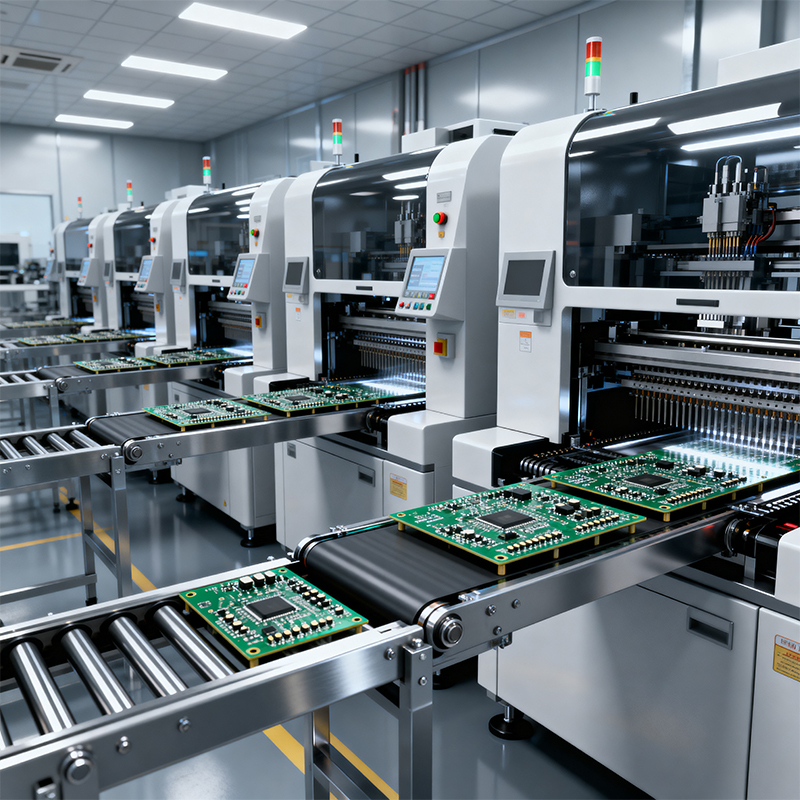

Professional Manufacturing & Process Control

Soldering one board isn't hard. Ensuring that ten thousand boards have identical soldering quality requires professional equipment and strict process control. This means precise management of every parameter, from solder paste printing accuracy to reflow oven temperature profiles. This is where the core expertise of an EMS lies.

Building Effective Quality Gates

The test plan is the goalkeeper for product quality. A good EMS partner won’t just do a simple power-on test. They’ll work with you to design targeted tests—functional, burn-in, environmental stress screening—based on how your product will be used, catching issues before they leave the factory.

Handling Everything After the Boards Are Made

Once the boards are produced, they often need to be housed, connected, programmed, labeled, and packed. A full-scope EMS service can handle all of this, right up to arranging export logistics. What you receive is truly a “finished good.”

From our conversations with clients, the decision to explore EMS usually comes down to a few practical realities:

Letting Your Team Focus on What They Do Best

Your core strength is likely innovative design or sharp market insight. Having your best engineers spend their days chasing parts and monitoring production lines is a waste of talent. EMS lets your team refocus on creating value.

Responding Agilely to Market Changes

Product demand has peaks and valleys. The fixed costs of your own factory can become a heavy burden during slow periods. The EMS model provides production-on-demand, letting you navigate market fluctuations more nimbly.

Controlling the True Total Cost

On the surface, outsourcing includes a service fee. But when you factor in the depreciation of equipment, facility costs, management salaries, inventory costs, and trial-and-error expenses of running your own factory, the overall economics of EMS often look more favorable—especially for small to medium batch sizes.

Leveraging Professional Experience, Avoiding Pitfalls

Manufacturing is full of “tribal knowledge.” A mature EMS partner has seen countless projects. They know which design choices aid production and which processes ensure long-term reliability. That knowledge becomes yours to benefit from.

When evaluating a potential partner, pay attention to these areas:

Is Communication Direct and Clear?

An ideal partner operates with transparency. You should be able to see production status, quality data, and issues openly. Good partnership is built without information barriers.

Are They Responsive?

Change is constant in product development. Can your partner quickly understand your needs and mobilize internal resources to adapt, rather than responding with “our process doesn’t allow that”?

Is Quality a Real Priority, or Just a Slogan?

Ask how they manage quality. What are the key inspection points? What’s their process when a quality anomaly occurs? Their answers reveal their operational depth.

Do They Genuinely Understand Your Product Goals?

Are they willing to invest time in understanding what problem your product solves and where it will be used? Understanding the “why” is crucial for executing the “how” well.

At the end of the day, finding an EMS partner is about securing a reliable foundation for your business. When this partnership works, manufacturing transforms into a powerful force that helps you bring innovative ideas to market faster and more reliably.

In Shenzhen, for EMS providers like Kaboer who own their factories, the core value lies in deeply integrating local supply chain efficiency and manufacturing flexibility with the client’s product vision. The most successful collaborations we see are ones where the client focuses on defining the “what,” and we apply our expertise to efficiently solve the “how.”

If the manufacturing process is starting to feel like it’s holding you back, it might be the right time to take a closer look at the EMS model.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..