Date: 2026-01-07

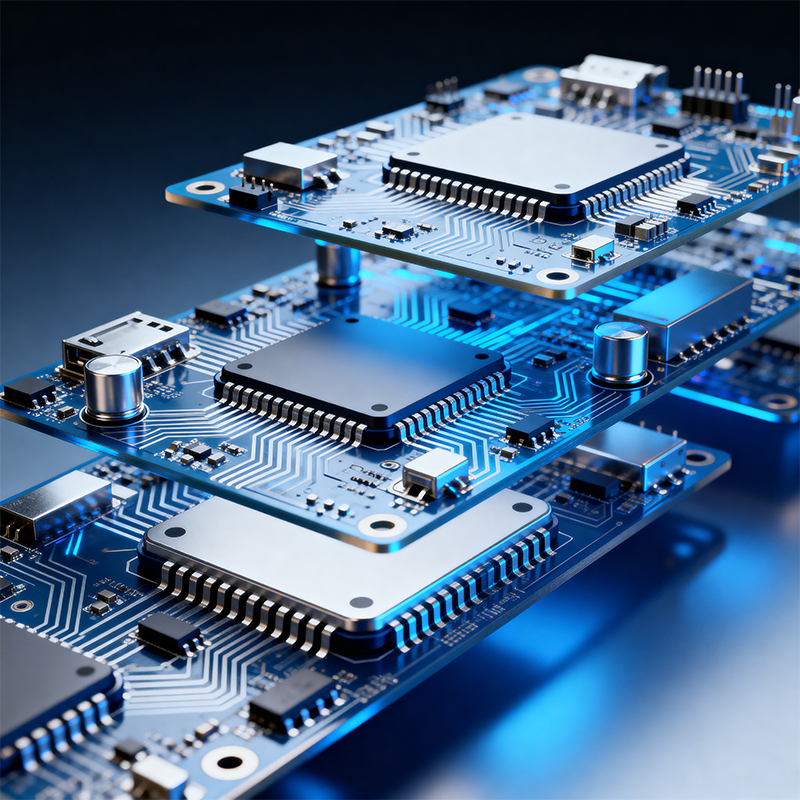

If you're searching for "PCB hardware," you're likely looking beyond circuit diagrams—you need guidance on turning those designs into physical, working products. This is about transforming "soft designs" into "hard products."

In simple terms, PCB hardware refers to the fully assembled, functional circuit board. It's not just lines and symbols in design software, but the physical, functional core of your product that you can actually hold in your hand.

A common question in product development is: why do similar circuit designs lead to products with vastly different performance? The answer often lies not in the design itself, but in the translation from design to hardware.

The Real Impact of Material Selection

A "10uF capacitor" in your design might have dozens of real-world counterparts. Components from different manufacturers vary significantly in high-temperature performance, lifespan, and cost. A quality PCB hardware manufacturer can recommend suitable materials based on your product's actual needs—like whether it needs to operate in high temperatures for extended periods.

Manufacturing Processes Determine Final Quality

The same design files, manufactured with different process capabilities, can yield completely different results. For example, imprecise soldering temperatures can cause weak connections, while improper cleaning might leave corrosive residues. At Kaboer's Shenzhen factory, we've learned that process details often separate reliable hardware from problematic ones.

The Completeness of Testing and Validation

Hardware testing goes beyond "powering it on to see if it works." True professional testing includes extended burn-in, temperature cycling, vibration tests, and more—proactively identifying issues that might appear during long-term use.

When it's time to transform your design into actual products, your manufacturing partner's capabilities directly impact the outcome.

Assess Their Depth of Understanding

A good partner tries to understand your product's end use. Is it for automotive electronics needing to withstand temperature extremes? Or consumer electronics where cost matters but appearance is also key? Different applications place completely different demands on hardware manufacturing.

Evaluate Their Transparency

Do they proactively share production status, quality control data, and issue resolution processes, or do you have to constantly follow up? Transparent partnerships significantly reduce project management uncertainty.

Consider Their Flexibility and Responsiveness

Design tweaks, component changes, schedule adjustments—these are common during product development. Can your partner respond quickly to these changes, or are they stuck in rigid processes? This has been a critical lesson from our Shenzhen factory's work with global clients.

Shenzhen's real advantage as a global electronics hub isn't just "low cost"—it's the complete supply chain and rapid response capabilities. You can have a prototype in hand within days of finalizing a design concept, and complete design iterations with new boards within a week.

At Kaboer, our operating model combines Shenzhen's supply chain strengths with rigorous quality management systems. We find the most successful projects are those that establish strong trust and transparent communication early in the hardware manufacturing phase.

PCB hardware manufacturing requires specialized knowledge, precision equipment, and disciplined processes. When your project needs to move from diagrams to physical products, choosing a partner who understands design intent while controlling manufacturing details can be the key to success.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..