Date: 2026-02-02

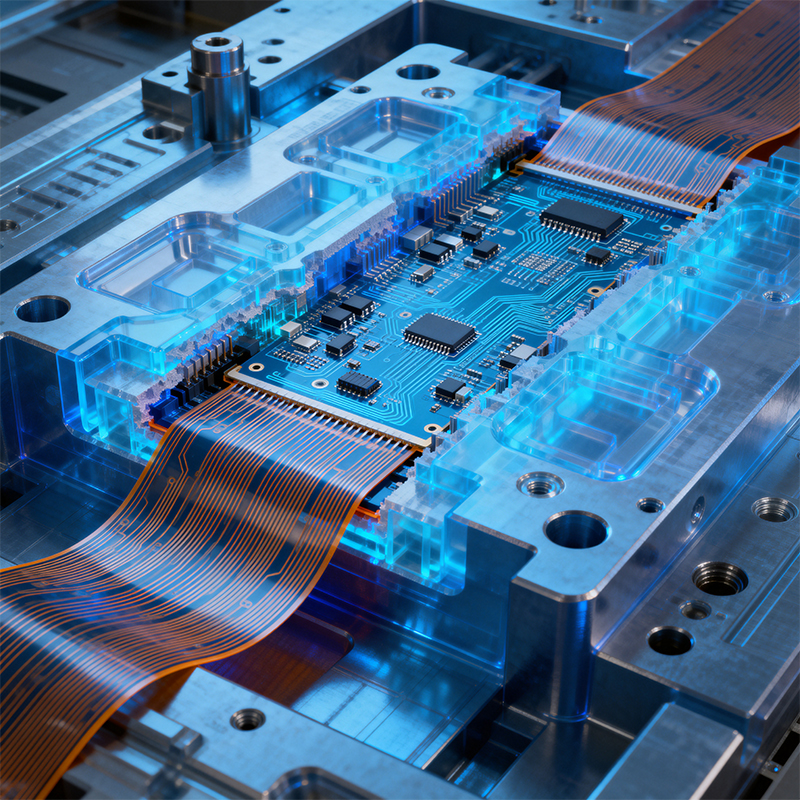

At the final stage of manufacturing a flexible circuit board (Flex PCB), engineers aren't dealing with a traditional rectangular shape, but rather with delicate parts that might be curved, irregular, or even have complex internal cutouts. How do you precisely, efficiently, and cleanly cut these interconnected flexible panels into their final shapes without damaging the material? The answer lies in a precision cutting technology known as the flex mold.

In simple terms, a flex mold is a specialized tool custom-designed for the precise outline blanking and forming of a specific flexible circuit board. It is typically a hardened steel plate, but through precision machining, its cutting edge is "engraved" with the exact shape and holes of the target PCB. Under pressure, it acts like a cookie cutter, "stamping" the flexible panel into the required profile in a single action.

The manufacturing and application of a flex mold is a customized process that blends precision mechanics with materials science.

1. Design & Engineering

It all starts with the final design file of the Flex PCB (usually a Gerber or CAD file with the exact outline). Mold engineers design the mold's structure based on the board's material (like polyimide), thickness, and shape complexity. The most critical part is determining the die line path, cutting angles, and clearances, which directly affect cut quality and mold lifespan.

2. Material & Fabrication

The mold base is typically made of high-hardness, high-wear-resistance tool steel. The core manufacturing steps involve precision wire EDM (Electrical Discharge Machining) and laser cutting. Wire EDM uses a thin electrified wire to erode the steel, creating highly precise straight edges and complex internal holes. Laser cutting excels at handling finer, more intricate curves. After cutting, grinding, and heat treatment, the mold's cutting edge becomes sharp and durable.

3. Multilayer Flex & Compound Tooling

For more complex structures like multilayer flex or rigid-flex boards, where different areas have varying thicknesses, a single cut might not suffice. This is where stepped dies or progressive die processes come in. A stepped die has cutting edges at different heights within the same tool, allowing for layered cutting of different thickness zones. Progressive die processing uses multiple dies in sequence to complete steps like rough cutting, fine cutting, and stiffener attachment.

Several primary methods exist for shaping flexible circuits:

Die Cutting: Best for medium to high-volume production. It's extremely fast (seconds per stroke), offers exceptional consistency, and produces clean, burr-free edges. While the mold itself has a high upfront cost, the per-unit cost becomes very advantageous over thousands of parts, with no thermal effects on the material.

Laser Cutting: Best for low-volume, high-complexity prototyping. No tooling is needed; the cutting path can be changed quickly via programming, offering great flexibility. However, it's slower for mass production, and the laser's heat can slightly alter the material properties at the cut edge.

Knife/Steel Rule Die Cutting: Suitable for thinner materials and simpler shapes, generally offering lower precision and longevity than solid steel dies.

A successful blanking process involves more than just a mold and a press.

Stripping & Waste Removal: After cutting, the surrounding waste material (skeleton) must be cleanly stripped and automatically ejected, while the tiny flexible circuits remain intact on the carrier film. This relies on precise ejector pin systems and vacuum waste removal.

Material Registration: Flexible materials are thin and prone to deformation. Ensuring the panel is in an absolutely precise position before each cut requires high-accuracy optical alignment systems or mechanical registration holes.

Mold Maintenance: The cutting edge wears over time. Regular sharpening and maintenance are key to maintaining cut quality and extending the mold's service life.

As electronics become thinner and more integrated, flex mold technology is also advancing. For instance, "Die-Cut & Laminate" inline processes are becoming increasingly popular. These systems continuously perform multiple steps—like blanking the outline, stripping the waste, and automatically laminating conductive adhesives or stiffeners—on a single machine line, significantly boosting production efficiency and product consistency.

In summary, the flex mold is the critical bridge connecting flexible circuit board design with reliable mass production. Though often behind the scenes, it is the unsung hero ensuring that every flexible circuit board precisely matches its design and fulfills its intended function. Understanding this technology helps product developers and manufacturers better plan the path from prototype to volume production.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..