Date: 2026-02-04

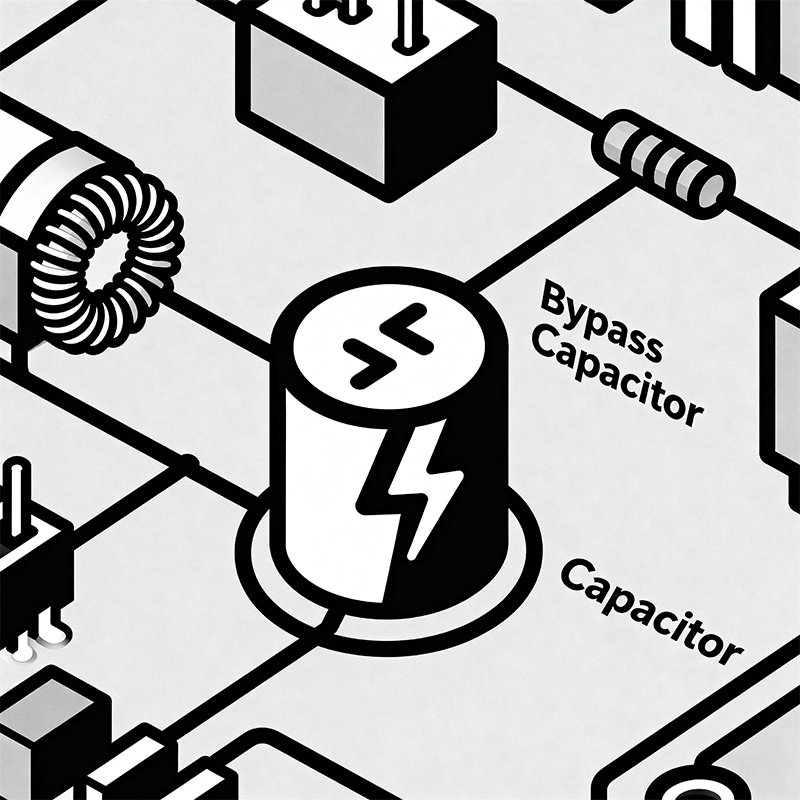

Among the dense components on a circuit board, there's a very small but critically important capacitor always placed right next to a chip's power supply pins, like a loyal guard. It's called the bypass capacitor (also known as a decoupling capacitor). Think of it as a "local energy reservoir" or a "local battery" for the chip.

Its core job is simple yet vital: to provide instantaneous bursts of current to the chip and filter out noise on the power supply line, ensuring the chip receives clean, stable power.

Ideally, the power supply line to a chip should be like a wide, smooth, and perfectly steady "energy highway." In reality, this "road" has two main issues:

The Path Itself Has "Resistance" and "Inertia": Even short PCB traces have tiny resistance and, more importantly, inductance. Inductance resists rapid changes in current.

Chips Are "Pulsed" Loads: Components like microprocessors and digital logic ICs don't draw constant current. For instance, when millions of transistors switch simultaneously on a clock edge, they create a massive, short-duration (nanoseconds) current demand spike.

Here's the problem: When the chip suddenly needs a large current pulse, the distant power supply can't respond instantly due to the inductance and resistance in the power path. This causes the voltage at the chip's power pin to momentarily sag, creating a brief voltage droop (noise) known as "power supply noise" or "ground bounce." This noise can cause digital circuits to malfunction or severely degrade the performance of sensitive analog circuits (like ADCs, RF modules).

The bypass capacitor solves this through a simple physical process:

Energy Storage: When the chip's current demand is low, the capacitor charges up, storing electrical energy.

Instantaneous Supply: When the chip needs a large current pulse, the nearby capacitor, thanks to its very low internal resistance and inductance, can instantly release its stored energy. It acts like a small "magazine," quickly "filling" the voltage gap to keep the voltage stable at the chip's pin.

High-Frequency Noise Filtering: Simultaneously, the capacitor presents a very low impedance (almost a short circuit) to high-frequency signals. Thus, high-frequency switching noise on the power line is effectively "bypassed" by the capacitor to ground, preventing it from entering the chip.

A Simple Analogy: If the main power supply is a distant large reservoir (slow to respond but high capacity), the bypass capacitor is the fire water tank right outside the chip's door (extremely fast to respond but small capacity). When a "small fire" (current spike) occurs, the distant reservoir can't send water in time, but the local tank can put it out immediately.

Not just any capacitor placed anywhere will work perfectly. Design considerations include:

Capacitance Value Selection: A combination of large and small capacitors is typically used.

Large Capacitors (e.g., 10µF, 100µF electrolytic or tantalum): Handle lower-frequency current fluctuations, providing "strategic reserves."

Small Capacitors (e.g., 0.1µF, 0.01µF ceramic): Handle high-frequency (MHz to GHz range) current spikes and noise—the "rapid response force." Smaller values generally have higher resonant frequencies, making them more effective at higher frequencies.

Placement is Extremely Critical: The bypass capacitor must be placed as close as possible to the chip's power pin! If placed too far away, the parasitic inductance introduced by the connecting trace severely degrades the capacitor's high-frequency response, rendering it nearly useless. Short, wide traces are key.

Minimize the Loop: The path from the capacitor's ground terminal to the chip's ground pin must also be as short as possible, creating a tiny current loop to minimize loop inductance.

In summary, the bypass capacitor is a fundamental component that ensures the reliable operation of modern high-speed, high-density electronics. Though inconspicuous, it is the cornerstone for suppressing power supply noise, improving system immunity, and ensuring signal integrity. A good circuit design almost always starts with properly selecting and placing bypass capacitors for every critical chip.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..