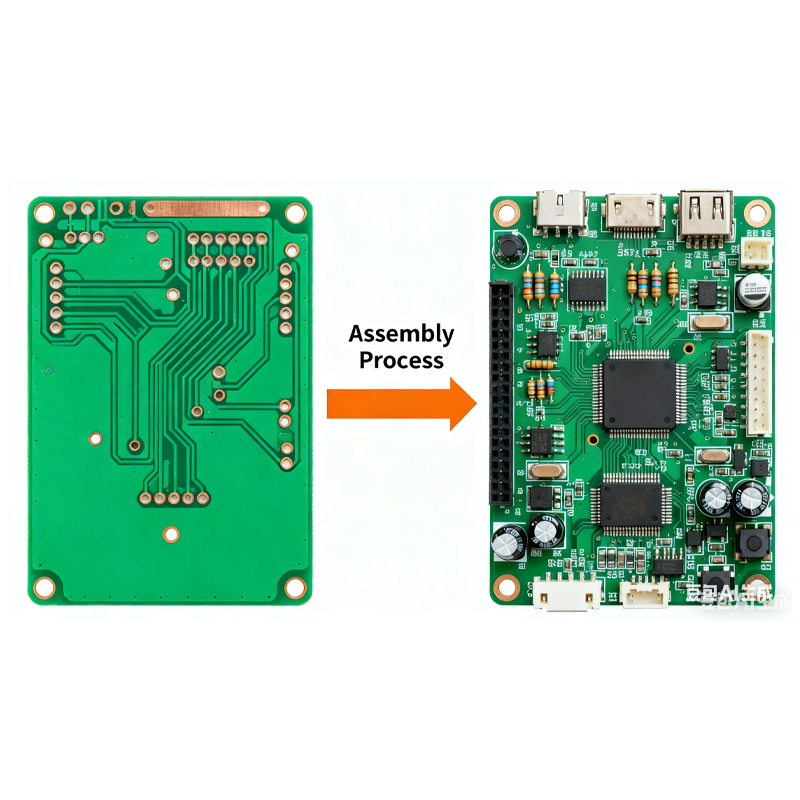

Let me walk you through how we turn empty circuit boards into working electronic assemblies. No engineering degree required to understand this.

Step 1: Checking All the Parts

Before we start building, we check everything:

-

We examine the bare PCBs for scratches, bad copper traces, or wrong dimensions

-

We verify all components - resistors, chips, capacitors - are the correct values and not damaged

-

Why we do this: Catching problems here saves us from building junk that doesn't work

Step 2: Getting Ready for Production

This is our setup phase:

-

We load components into tapes that our machines can read

-

We program our equipment with your board design - telling machines where to place each part and what temperature to use for soldering

-

Why we do this: Proper setup means everything runs smoothly during assembly

Step 3: Putting Components on the Board

We use two main methods:

-

Machine placement: Robots precisely place tiny components like resistors and chips onto the board

-

Manual insertion: For larger parts with wires or pins, we either hand-place them or use special insertion machines

-

Why we do this: This is where your board actually starts looking like an electronic assembly

Step 4: Making Everything Stick

We use different soldering methods:

-

For machine-placed parts: We run boards through ovens that melt solder paste to create permanent connections

-

For hand-inserted parts: We use wave soldering where boards pass over molten solder that wicks up through the holes

-

Why we do this: This creates the electrical connections that make your board actually work

Step 5: Testing and Fixing Problems

This is our quality control:

-

We visually inspect boards for bad solder joints, missing parts, or placement errors

-

We power up boards and test if they perform as intended

-

We repair any boards that fail our tests

-

Why we do this: We don't want to ship you boards that don't work

Step 6: Cleaning and Shipping

Final steps before your boards ship:

-

We clean off any flux residue or contaminants

-

We dry boards completely

-

We package them in anti-static materials for safe shipping

-

Why we do this: We want your boards to arrive clean and undamaged

The Bottom Line

This six-step process transforms bare boards into functional electronic assemblies ready for your products. Each stage has specific purposes and quality checks to ensure you receive working, reliable PCBAs.

We've refined this process over years of manufacturing, and it's what allows us to consistently deliver quality boards that work right out of the box. Whether you're building medical devices, consumer electronics, or industrial equipment, this approach ensures your boards will perform as expected.