Date: 2025-10-23

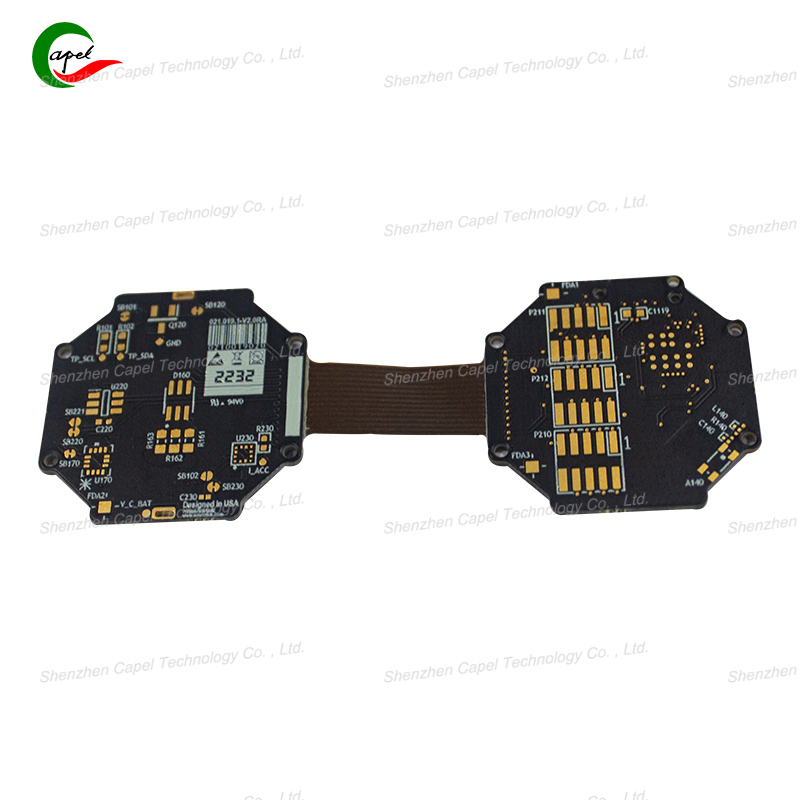

If you've ever examined the electronics behind a modern smart cockpit, you'll notice something that sets apart manufacturers like Tesla and BMW - their sophisticated use of rigid-flex PCB technology. Having worked with several automotive suppliers on cockpit integration projects, I've seen how this approach transforms what's possible in vehicle interior design.

Today's vehicles are essentially rolling networks of electronic systems. I recently worked on a luxury vehicle project that required connecting 15 different electronic modules within the cockpit space. The traditional approach of using separate PCBs connected by wiring harnesses was creating a nightmare of complexity.

The Space Constraint Problem

Modern cockpits are incredibly space-constrained. Between the curved displays, ambient lighting, and numerous sensors, every millimeter matters. I've seen designs where wiring harnesses alone consumed over 40% of the available space behind the dashboard.

Signal Integrity Concerns

The real challenge comes from managing high-speed data streams. When you're running 4K display signals alongside ADAS data and infotainment content, even minor impedance mismatches can cause visible artifacts or system lag.

Integrated Connectivity That Works

The ability to create a unified circuit that spans multiple cockpit areas is revolutionary. We recently designed a rigid-flex system that connected the center console, instrument cluster, and overhead console in one continuous circuit. This eliminated 23 separate connectors and reduced wiring weight by 55%.

Space Optimization Through 3D Design

Rigid-flex PCBs allow for three-dimensional routing that would be impossible with traditional approaches. I've designed circuits that wrap around structural elements, fit into tight spaces between components, and follow the contours of curved surfaces.

Reliability in Demanding Conditions

Vehicle interiors present harsh environments. Through extensive testing, we've validated that properly designed rigid-flex systems can withstand:

Temperature cycles from -40°C to 125°C

Vibration profiles matching worst-case road conditions

Mechanical stress from years of daily use

Material Selection Strategy

Through testing and field experience, we've found that certain materials work particularly well:

LCP substrates for high-speed data paths

High-temperature polyimide for general routing

Rolled copper for dynamic flexing areas

Design Approaches That Deliver Results

The transition between rigid and flexible sections requires careful attention. We use:

Gradual thickness transitions over 4-6mm distances

Strategic stiffening in component areas

Careful management of bend radii and stress points

Signal Integrity Management

Maintaining signal quality in flexible sections demands specific techniques:

Controlled impedance design throughout

Proper ground return paths

Separation of analog and digital signals

The results from production vehicles demonstrate the impact:

40-60% reduction in connection-related failures

30-50% space savings in crowded areas

Improved system responsiveness and reliability

One automaker reported eliminating 85% of their cockpit wiring issues after switching to rigid-flex technology.

Thermal Management

Early designs struggled with heat dissipation in compact spaces. We've developed solutions using:

Thermal vias in rigid sections

Strategic component placement

Advanced thermal interface materials

Manufacturing Consistency

Achieving reliable mass production requires:

Tight process controls

Comprehensive testing protocols

Close collaboration with manufacturing partners

Start with High-Value Applications

We typically begin with:

Display and control systems

Critical safety components

Complex multi-module connections

Prototype and Test Thoroughly

Physical validation is essential. We recommend:

Environmental testing across the full temperature range

Vibration testing simulating actual road conditions

Long-term reliability testing

The technology continues to evolve. We're working on:

Even higher integration levels

Improved thermal performance

Advanced signal integrity solutions

Rigid-flex PCBs have moved from being a specialty solution to a fundamental enabling technology for modern vehicle cockpits. The integration benefits, space savings, and reliability improvements they provide are essential for meeting the demanding requirements of today's smart cockpits.

For engineering teams working on next-generation vehicles, mastering rigid-flex design is becoming essential for creating competitive products. The companies that embrace this technology today will be the ones setting the standards for cockpit innovation tomorrow.

The transition to rigid-flex PCBs represents more than just a component change - it enables fundamentally better cockpit designs that can meet the increasing demands for connectivity, features, and reliability.

related link:

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..