Date: 2026-01-21

Let’s be honest—seeing a new circuit board design covered in tiny, flat components can be intimidating. For a prototype or a small batch, sending it to an assembly house might feel like overkill. And when a single component fails on an otherwise good board, the thought of reworking it yourself might seem like a job for a neurosurgeon.

But here’s the good news: soldering surface mount (SMD) components by hand is absolutely a skill you can learn. It doesn’t require magic, just the right approach and a bit of practice.

This guide will walk you through the core methods, from the simplest to the more advanced, using plain language. Think of it as having a practical toolkit for different situations.

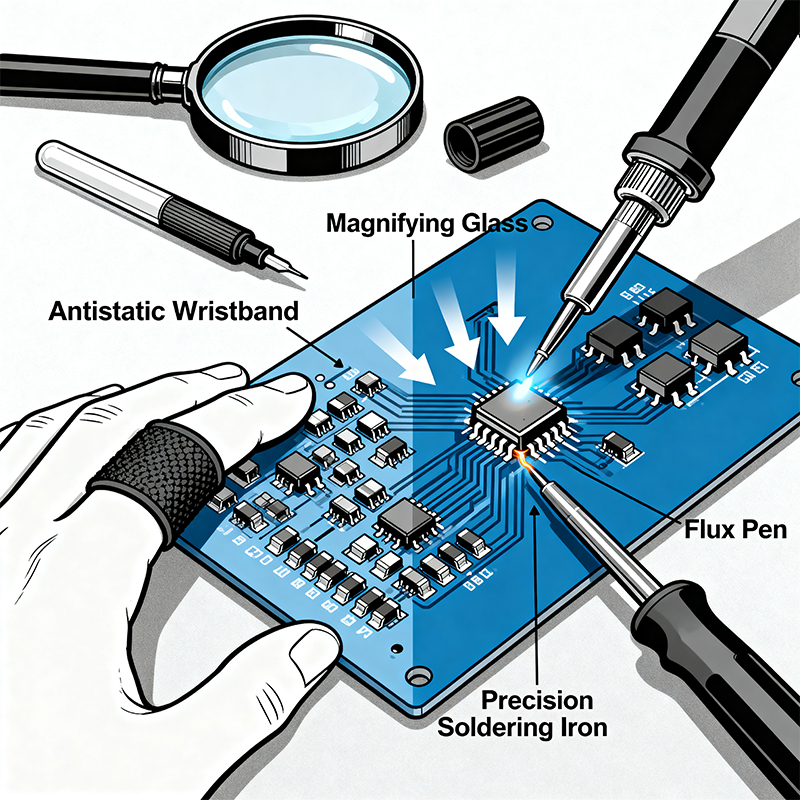

Before you start, gather a few essential tools. You don’t need a $10,000 lab setup, but a few key items make all the difference:

A Good Temperature-Controlled Soldering Iron: A fine, conical tip (like a 0.8mm or 1mm) is your best friend for precision work.

Fine-Gauge Solder: Thin solder wire (0.5mm or 0.015" diameter) with a flux core is much easier to control than the thick stuff used for plumbing.

Flux: This is the secret sauce. Flux is a chemical cleaner that makes solder flow beautifully. Having a small syringe or pen of no-clean flux will dramatically improve your results. Don't skip this.

Tweezers: A good pair of non-magnetic, fine-point tweezers is your "third hand."

Magnification: A helping hands magnifier, a bench magnifying lamp, or even a cheap USB microscope will save your eyes and help you see what you're doing.

Desoldering Braid & Wick: For cleaning up mistakes and removing excess solder.

Isopropyl Alcohol & a Brush: For cleaning off flux residue after you're done (if you're not using "no-clean" flux).

This is the go-to method for soldering chips with pins on two or four sides (like SOIC, TSSOP packages). It looks advanced but is quite logical.

Step-by-Step:

Position & Tack: Place the chip perfectly aligned on its pads. Then, apply a tiny bit of solder to just one corner pin to tack it in place. This holds the chip steady.

Flux is Your Friend: Apply a generous amount of liquid flux along all the pins on one side of the chip. This isn't wasteful; it's crucial.

The "Drag": Load a small bead of solder onto your iron tip. Gently touch the tip to the end of the row of pins and slowly drag it along the entire row. The flux will pull the molten solder onto each pin and pad, creating perfect joints. Don't add more solder during the drag—let the bead on your iron do the work.

Inspect & Repeat: Check for bridges (solder connecting two pins). If you see one, add more flux and use your clean soldering iron tip or desoldering braid to wick up the excess. Repeat on the other sides.

Clean Up: Once all sides look good, clean the area with isopropyl alcohol to remove the leftover flux.

Pro Tip: If you create solder bridges, don't panic. Adding more fresh flux and re-running a clean tip along the pins will often fix it. The flux breaks the surface tension and pulls the excess solder onto the iron.

If the "drag" method feels too daring, this is a fantastic, controlled alternative.

Step-by-Step:

Tack in Place: Just like before, align and tack one pin.

Flood with Solder: This feels wrong but trust the process. Liberally apply solder so that all the pins on one side are bridged together in one big blob. The goal is to ensure every pin is covered.

The Magic Wick: Lay a piece of desoldering braid over the blob of solder. Press down on it gently with your hot soldering iron tip. The braid will act like a sponge, soaking up all the excess solder. As you pull the braid away, you'll be left with clean, separated, shiny solder joints.

Repeat & Clean: Do this for each side and clean with alcohol.

For these tiny chips (like 0805, 0603, or smaller), the process is different.

Step-by-Step:

Tin One Pad: Apply a tiny amount of solder to just one of the two pads on the circuit board.

Position & Reflow: While the solder on that pad is still molten, use your tweezers to place the component onto its pads, sliding it into the tiny solder puddle. Remove the iron and hold the component steady for a second until the solder solidifies. It’s now held in place by one end.

Solder the Other Side: Simply touch your iron and a tiny bit of solder to the other pad and the component’s end to form the second joint.

Revisit the First Joint: Briefly reheat the first joint to ensure it’s perfect and stress-free.

Pro Tip: Use plenty of flux here too. It helps the solder flow neatly onto the small metal ends of the component.

For components with no visible pins underneath (like BGA chips) or for removing multi-pin parts, a hot air gun is essential.

How It Works:

For Removal: Apply flux around the component. Use a nozzle that directs heat to the component, not the whole board. Gently heat in a circular motion. Once the solder under all pins is molten, you can lift the chip off with tweezers.

For Installation: Place new solder paste on the pads, position the component, and then evenly heat it with the hot air gun until you see the solder reflow (it will "snap" into place as surface tension aligns it). This requires practice and good temperature control.

Warning: Hot air can easily damage nearby plastic components or lift pads if you're not careful. Always start with low airflow and temperature, and shield adjacent parts with high-temperature Kapton tape if needed.

Hand soldering is perfect for:

Prototyping and one-off builds.

Rework and repair of existing boards.

Small batch modifications.

However, for any production run—even 50 units—this process does not scale. The time, inconsistency, and potential for hidden defects ("cold joints") make automated SMT assembly the only sensible choice. This is precisely where the expertise of a professional PCBA manufacturer becomes critical.

A manufacturer like Kaboer, with its automated SMT lines in Shenzhen, uses precisely controlled processes—solder paste stenciling, high-speed pick-and-place machines, and reflow ovens with exact temperature profiles—to achieve perfect, reliable solder joints on hundreds of boards per hour. This is the difference between a functional prototype and a shippable product.

So, master these hand-soldering skills for your bench work. They’re incredibly valuable. But when it’s time to manufacture, partner with experts who specialize in scale, consistency, and reliability. Knowing how it’s done manually gives you a deeper appreciation for—and a better ability to evaluate—the quality of the automated assembly you receive.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..