Date: 2025-12-27

A Manufacturing Specification is a comprehensive, formal document or set of documents that precisely defines all requirements, parameters, processes, and acceptance criteria for producing a component or final product. In electronics manufacturing, it acts as the definitive “rulebook” that bridges the gap between design intent and mass-produced reality. It ensures that every unit built, regardless of where or when it is made, meets the same performance, reliability, and quality standards.

For electronics manufacturers, a well-defined manufacturing specification is not just paperwork; it is the foundation of quality control, supply chain management, and product reliability.

A Manufacturing Spec translates a product’s design goals into actionable, measurable, and verifiable instructions for the factory floor. It answers the critical question: “How must this product be built and verified?”

It is Objective: Based on measurable data, not subjective opinion.

It is Authoritative: It overrides general practices with product-specific requirements.

It is Communicative: It aligns all stakeholders—design engineers, process engineers, quality teams, and contract manufacturers.

Their importance spans the entire product lifecycle:

Ensures Consistency & Quality: Eliminates ambiguity, ensuring every production run yields identical, high-quality products.

Enables Efficient Sourcing: Allows manufacturers to accurately quote, source materials, and plan production.

Facilitates Compliance: Provides the evidence needed to meet industry regulations (e.g., ISO, IPC, automotive standards).

Reduces Risk & Cost: Prevents costly errors, rework, and field failures by defining requirements upfront.

Resolves Disputes: Serves as the objective reference for quality acceptance between customer and supplier.

A robust spec is typically a compilation of several key documents:

| Document Type | Purpose & Content | Examples/Standards |

|---|---|---|

| 1. Technical Product Specification | Defines the what. Details the product’s functional, mechanical, and electrical requirements. | Schematics, Gerber files, Bill of Materials (BOM), approved vendor list (AVL), mechanical drawings. |

| 2. Quality & Workmanship Standards | Defines how good it must be. Specifies the acceptability criteria for the assembly. | IPC-A-610 (Acceptability of Electronic Assemblies) with a defined Class (1, 2, or 3). Customer-specific criteria for cosmetic defects. |

| 3. Process Specifications | Defines how to build it. Details the specific methods, materials, and settings for each step. | Solder paste type & stencil specification, reflow oven temperature profile, cleaning process, conformal coating material & thickness. |

| 4. Test & Verification Specification | Defines how to verify it. Outlines all inspections and tests required to validate the product. | In-Circuit Test (ICT) procedures, Functional Test (FCT) requirements, burn-in/environmental test parameters, sampling plans (based on AQL). |

Manufacturing specs often invoke established industry standards to define requirements concisely.

IPC Standards: The global benchmark for electronics assembly.

IPC-A-610: The most widely used acceptability standard for soldered assemblies.

IPC-J-STD-001: Requirements for soldered electrical and electronic assemblies.

IPC-7711/7721: Standards for rework, modification, and repair.

ISO Standards: Framework for quality management systems.

ISO 9001: Quality management systems requirements.

IATF 16949: Quality management standard specifically for the automotive industry.

Customer-Specific Standards: Large OEMs (e.g., in automotive, aerospace) often have their own supplemental standards.

Be Specific and Unambiguous: Use precise language, numbers, and references. Avoid “good,” “sufficient,” or “as per standard”—define what that means.

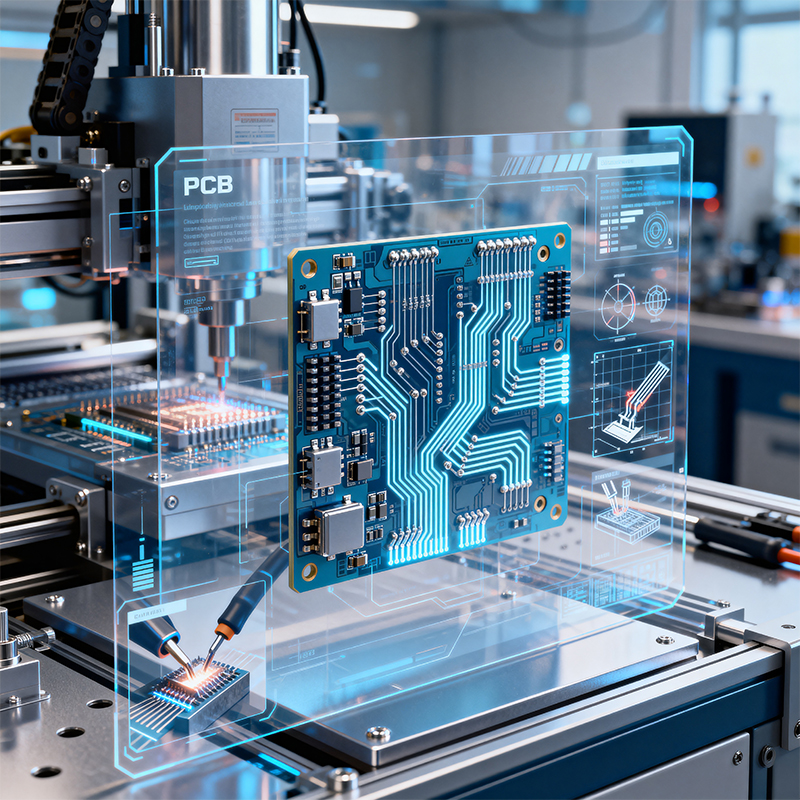

Incorporate Visual Aids: Use annotated photographs, diagrams, and drawings to illustrate acceptable and unacceptable conditions (a “golden sample” is ideal).

Define Measurement Methods: Specify how to measure a parameter (e.g., “X-ray voiding shall be measured per IPC-7095”).

Version Control is Mandatory: Every specification must have a clear title, unique document number, revision letter, and effective date. Obsolete versions must be archived.

Collaborative Creation: The spec should be developed with input from design, manufacturing, and quality teams to ensure it is both aspirational and achievable.

Q1: What is the difference between a Design Specification and a Manufacturing Specification?

A: A Design Specification defines what the product should do (function, performance, features). A Manufacturing Specification defines how the product must be built and verified to achieve that design. The former is for engineers; the latter is for the factory.

Q2: Who is responsible for creating the manufacturing specification?

A: Typically, the Original Equipment Manufacturer (OEM) or product designer owns the specification. However, it is often created in collaboration with, or with significant input from, the manufacturing partner who provides expertise on process capabilities and Design for Manufacturability (DFM).

Q3: What happens if there is a conflict between documents in the specification set?

A: The specification should define a document hierarchy. A common rule is: Customer-Specific Requirements > Detailed Product Spec > Referenced Industry Standard > General Factory Practice. Any conflict must be formally clarified by an engineering change order (ECO).

Q4: How detailed should a manufacturing specification be?

A: It should be as detailed as necessary to eliminate guesswork, but not so restrictive that it prevents process optimization. It should focus on the “what” and “why” (the requirement), often allowing the manufacturer some freedom on the “how” (the specific process), provided they can consistently meet the stated requirements.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..