Date: 2025-12-19

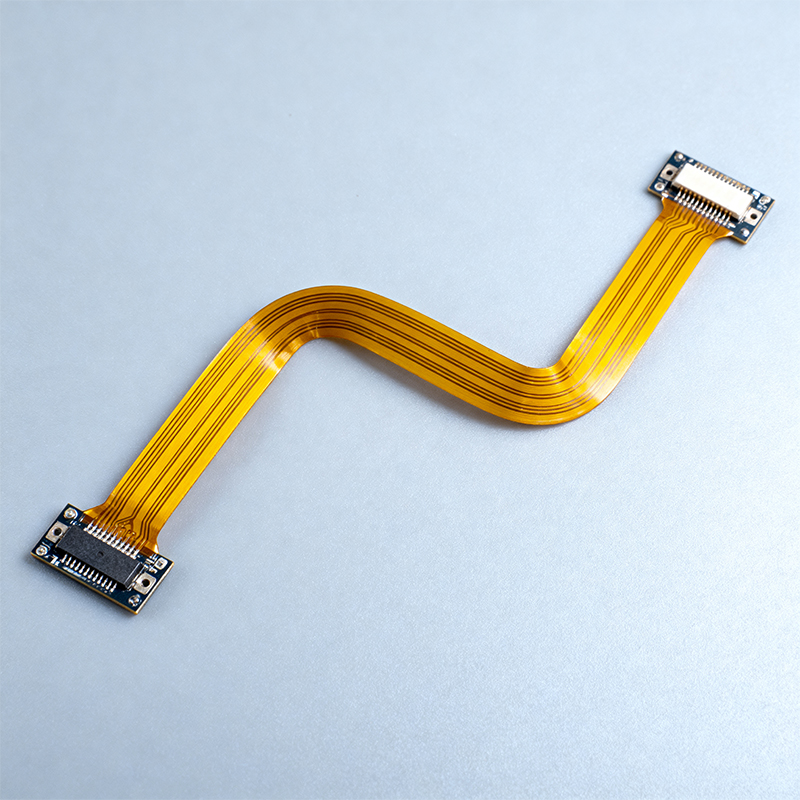

A Multilayer Printed Circuit Board (PCB) is a complex circuit board consisting of three or more conductive copper foil layers laminated together with insulating dielectric material, forming a single, compact structure. These layers are interconnected through plated through-holes (PTHs), blind vias, or buried vias, allowing for sophisticated circuit routing in a limited footprint. Unlike single or double-sided PCBs, multilayer boards enable higher component density, reduced electromagnetic interference (EMI), and more efficient use of space—making them essential for modern electronics like smartphones, medical devices, automotive systems, and communication equipment.

By stacking multiple conductive layers, multilayer PCBs accommodate more components and complex wiring in a smaller area, supporting the miniaturization trend in electronics.

Dedicated power and ground planes, along with controlled impedance routing, reduce noise, crosstalk, and EMI, improving overall device reliability.

Engineers can isolate sensitive signals, manage heat distribution more effectively, and create more robust and reliable products.

Despite multiple layers, the laminated construction often results in a strong, lightweight board suitable for demanding applications.

| Layer Count | Typical Applications | Key Characteristics |

|---|---|---|

| 4-Layer | Consumer electronics, automotive modules | Includes internal power and ground planes; good balance of cost and performance |

| 6-8 Layer | Industrial controls, networking hardware | Additional signal layers for moderate complexity; better EMI shielding |

| 10+ Layer | Servers, telecommunications, medical imaging | High-speed designs requiring multiple signal, power, and ground planes |

| 16+ Layer | Aerospace, military, advanced computing | Extreme density and signal integrity requirements; complex via structures |

Proper arrangement of signal, ground, and power layers is critical for managing impedance, reducing noise, and ensuring thermal performance.

High-Tg (glass transition temperature) FR-4, Rogers, or polyimide materials may be chosen based on thermal, mechanical, and electrical requirements.

Through-hole, blind, and buried vias must be strategically planned to maximize routing space while maintaining reliability.

Internal heat dissipation must be addressed through careful placement of thermal vias, copper pours, and sometimes metal cores.

Critical for high-speed circuits, requiring precise dielectric thickness and trace width calculations.

Maintaining precise alignment between layers during lamination is essential to ensure reliable interconnections.

Inadequate press cycles or material contamination can cause layers to separate or create voids, compromising board integrity.

Ensuring consistent copper deposition in deep vias and through-holes is technically demanding but critical for conductivity.

As layer counts increase, managing crosstalk, skew, and reflections becomes more challenging.

Electrical testing (flying probe, fixture-based) and advanced inspection (AOI, X-ray) are more complex and time-consuming for multilayer boards.

Navigating the complexities of multilayer PCB design and manufacturing requires a partner with proven technical expertise and reliable production capabilities. At Kaboer, we specialize in delivering high-quality, multilayer PCBA solutions from our state-of-the-art factory in Shenzhen, China—the heart of global electronics manufacturing.

Advanced Manufacturing: We produce reliable multilayer PCBs from 4 to 24+ layers, supporting complex designs with controlled impedance, blind/buried vias, and stringent impedance control.

Comprehensive Engineering Support: Our team provides Design for Manufacturability (DFM) analysis to optimize your multilayer stack-up, via strategy, and thermal management before production begins.

Full Turnkey PCBA Service: From component sourcing and precise SMT assembly to thorough testing and final packaging, we manage the entire process under one roof.

Quality Assurance: We implement rigorous testing protocols, including Automated Optical Inspection (AOI), X-ray inspection for BGAs and vias, and functional testing to ensure every board meets international standards.

Whether you are developing next-generation IoT devices, automotive electronics, or industrial control systems, Kaboer has the expertise to transform your complex multilayer PCB designs into reliable, high-performance products. Contact us today to discuss how we can support your next project with precision manufacturing and competitive global supply chain advantages.

Multilayer PCBs represent more than just a technical solution—they enable the innovation and miniaturization driving today's electronics industry. Success with these complex boards depends on thoughtful design, material selection, and, crucially, partnership with a manufacturer that understands both the technical nuances and the business imperatives of producing reliable, cost-effective multilayer solutions.

By mastering multilayer PCB technology, electronics manufacturers can create products with superior performance, enhanced reliability, and competitive advantages in an increasingly demanding global marketplace.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..