Date: 2026-01-05

When you search for "SMT manufacturing," you likely know SMT stands for "Surface Mount Technology." But in daily practice at a Shenzhen factory, it represents not just a single technology but a complete manufacturing ecosystem—the entire process from receiving your design files to delivering finished circuit boards.

Simply put, SMT is the modern method of using precision equipment to "mount" miniature electronic components onto the surface of a circuit board and solder them in place. Think of it like using an ultra-precise applicator and hot air tool to perform assembly under a microscope.

Step 1: Stencil Printing – Laying the "Foundation"

Imagine using a stencil to sprinkle powdered sugar on a cake. We use laser-cut stainless steel stencils to precisely print solder paste onto the PCB pads. The accuracy required here is extreme—too much paste can cause shorts, too little can lead to weak joints. At Kaboer, we use Automated Optical Inspection immediately after printing to ensure every pad has a perfect deposit.

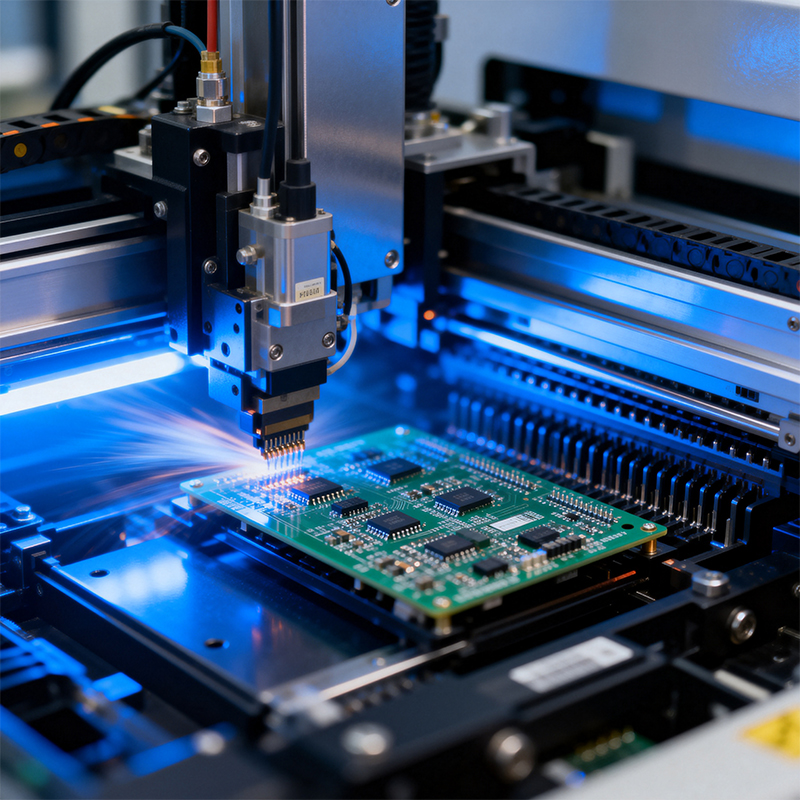

Step 2: Component Placement – A Millimeter-Scale "Pick & Place" Game

This is the mesmerizing part. The pick-and-place machine acts like a high-speed robotic hand, picking components—some smaller than a sesame seed—from reels and placing them onto the paste at speeds of tens of thousands of parts per minute. The equipment handles everything from tiny 01005-sized resistors to large BGA chips, all with micron-level precision, completely automatically.

Step 3: Reflow Soldering – The "Precise Dance" of Temperature

The populated PCB enters a reflow oven, following a carefully engineered temperature profile. This isn't simple heating and cooling—over 3-5 minutes, the solder paste goes through four phases: preheat, activation, reflow, and cooling. Precise temperature control ensures the paste melts completely to form reliable joints without damaging sensitive components from thermal stress. This stage is critical for soldering quality.

Step 4: Automated Inspection – The "Eagle Eyes" of Quality Control

After soldering, boards don't just get boxed up. An AOI system scans each board with high-resolution cameras, checking for misaligned, missing, or reversed components. For chips with hidden solder joints like BGAs, X-ray equipment inspects the joint quality. We've found that catching issues at this early stage saves multiple times the cost compared to finding them during final testing.

Equipment Investment and Maintenance

A complete SMT line requires millions in equipment plus ongoing maintenance and calibration. For most companies, partnering with a professional factory that has established lines is more economical than building their own.

Accumulated Process Knowledge

Good soldering relies as much on experience as on equipment. What's the optimal temperature profile for different boards? How do you handle special components? What about moisture-sensitive parts? This knowledge comes from long-term practice.

Supply Chain and Material Management

SMT manufacturing involves sourcing, storing, and managing hundreds of component types. A professional factory's volume purchasing power and inventory systems ensure stable material supply, preventing production stoppages due to a single missing part.

At Kaboer in Shenzhen, our SMT lines process diverse orders from global clients every day. We find successful SMT partnerships are often built on three fundamentals: clear design files, open engineering communication, and shared understanding of quality requirements. If your team is evaluating SMT options—whether sourcing capacity for a new project or optimizing existing production—understanding these practical details can lead to better decisions.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..