Date: 2026-01-21

Think about the last time you connected two things. Maybe you plugged a USB cable into your laptop, or clicked a LEGO brick onto another. There was a satisfying click, and you knew a connection was made. Inside your electronic devices, a similar, often overlooked part does this job: the PCB header.

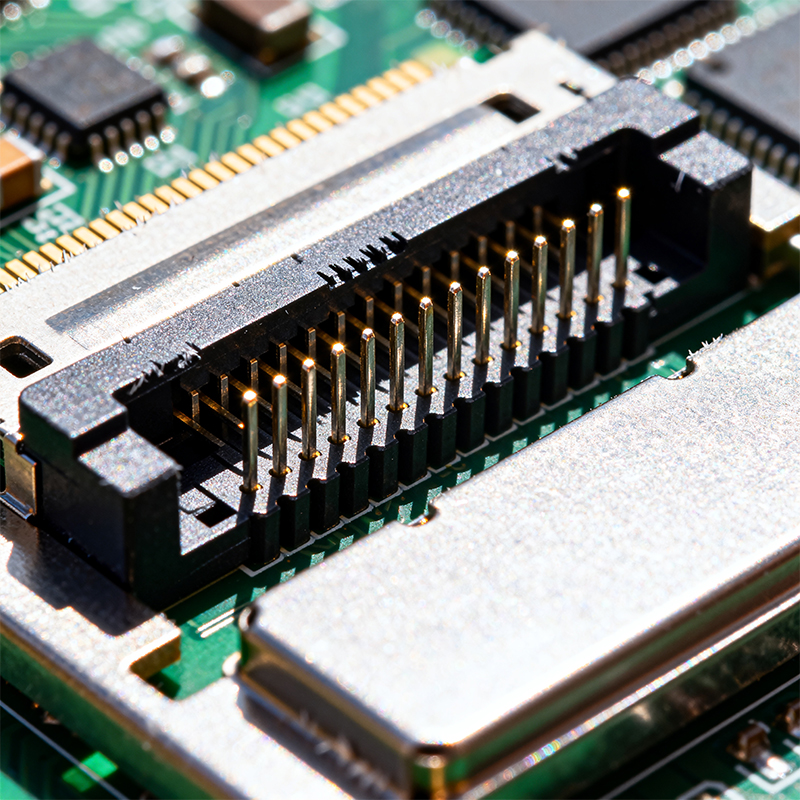

You've definitely seen them. They're those rows of plastic and metal pins sticking up from a circuit board. They might seem simple, but they're one of the most critical "meeting points" in electronics design. They're the reliable bridge that lets power, data, and signals travel between different boards or parts of a system.

Let's break down what they are, why they're everywhere, and what you need to know when using them.

In simple terms, a PCB header is a type of connector that gets soldered directly onto a printed circuit board. It's usually the "plug" or "socket" side of a connection that stays fixed to the board.

Think of it like this:

Your main PCB is like a city's central station.

The PCB header is the set of fixed platforms and docking points built into that station.

The cable or secondary board that plugs into it (often using a "mating connector" like a cable harness) is the train that arrives and connects.

The header is the permanent, soldered-in foundation for a temporary or semi-permanent connection.

Headers aren't there for decoration. They solve two fundamental problems in design:

Modularity: They let you split a complex system into smaller, manageable boards. Instead of one giant, hard-to-manufacture or repair PCB, you can have a main board, a display board, a sensor board, etc. Headers allow these modules to plug together and communicate. This is crucial for prototyping, upgrading, and repair.

I/O Access: They provide a clean, organized port for bringing signals and power on and off the board. Instead of soldering wires directly to tiny pads, you solder a header once. Then, cables can be plugged and unplugged safely and reliably for testing, programming, or connection to other system parts.

Not all headers are the same. The right choice depends on what you're connecting.

Pin Headers (The Classics): These are the simple, single or double rows of pins. They're incredibly common for board-to-board stacking or connecting to a breadboard for prototyping.

Box Headers / Socket Headers: These have a plastic shroud that surrounds the pins. This shroud acts as a guide, making it easier to plug in a matching cable connector (like a crimped IDC connector) without bending pins. They offer better reliability for cable connections.

Shrouded Headers: Similar to box headers but with an added feature: a polarizing key. This means the mating connector can only go in one way, preventing you from plugging it in backwards and damaging your circuit—a simple but brilliant feature.

Right-Angle Headers: Instead of sticking straight up, these pins come out at a 90-degree angle. This lets you connect another board parallel to the main one (like a "daughterboard"), saving vertical space inside a product's enclosure.

When selecting a header, engineers check a few key numbers:

Pitch: This is the distance between the centers of two adjacent pins, measured in millimeters. 2.54mm (0.1") is the standard, but you'll also see smaller pitches like 2.0mm, 1.27mm, or even 0.5mm for dense, compact designs. Matching the pitch between the header and its mating connector is non-negotiable.

Pin Count: How many connections do you need? Headers come in a vast range, from 2 pins to 40 pins or more.

Current Rating: How much electrical current can each pin safely carry? A signal pin might only need a fraction of an amp, while a power pin might need to handle 2A or more. This depends on the pin's thickness (gauge) and material.

Mounting Style: Through-hole (THT) headers have long pins that go through holes in the PCB and are soldered on the bottom. They're mechanically very strong. Surface-mount (SMT) headers sit flat on the board's surface. They're used for automated assembly and to save space on the bottom side of the board.

Headers look simple, but they can cause surprising issues on the production line:

Solder Wicking: For through-hole headers, if the solder process isn't controlled, molten solder can "wick" up the pin inside the plastic housing, creating a messy blob that can prevent the mating connector from plugging in fully.

Mechanical Stress: A header is a lever. If a stiff cable is plugged in and gets tugged, that force transfers to the solder joints on the board. If not properly supported (with a strain relief bracket or by being secured to the enclosure), these joints can crack over time.

Alignment & "Float": In board-to-board designs, if the two headers aren't perfectly aligned, you can't plug them together. Some SMT headers are designed with a little "float"—tiny mechanical play—to compensate for small misalignments during assembly.

This last point about manufacturing is key. A good PCBA partner doesn't just solder the part you specify onto the board. They understand how the assembly process interacts with the component.

At Kaboer, with our own assembly lines in Shenzhen, we see headers as a critical point of quality control. Our process is set up to prevent those "gotchas":

Our soldering profiles are tuned to minimize wicking on through-hole headers.

Our automated optical inspection (AOI) can check that every pin on a header is perfectly soldered and free of defects.

We can provide design feedback if we see a header placement that might cause mechanical stress or alignment issues in your final product assembly.

PCB headers are the humble, essential connectors that make modular and serviceable electronics possible. Choosing the right type and ensuring they are assembled flawlessly is a small detail that has a big impact on the reliability and manufacturability of your product. It's one of the many small things that, when done right, you never have to think about—and that's exactly the point.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..