Date: 2026-01-23

You've just received a batch of newly assembled circuit boards. You notice a smooth, glossy film covering most of the surface, leaving only connectors and test points exposed. This isn't a manufacturing mistake or leftover residue. That film is a deliberate, critical layer of protection called a coating on PCB.

Think of it like this: A finished circuit board fresh off the assembly line is like a newly paved road with all the streetlights installed. It works perfectly… in a clean, dry lab. But put it in the real world—with humidity, dust, sudden temperature changes, or accidental spills—and problems can start. The coating is like laying down a final, protective sealant over that road. It shields everything from the unpredictable elements, ensuring long-term reliability.

For device manufacturers, understanding this protective coating isn't just a technical detail; it's a key decision point for product durability. Let’s peel back the layers on what it is and why it matters.

A PCB coating, technically known as a Conformal Coating, is a thin, protective polymeric film applied to the surface of an assembled circuit board. Its job is to "conform" to the board's shape, covering components, solder joints, and exposed traces, creating a continuous barrier.

Its primary mission is defense:

Against Moisture & Contaminants: It prevents condensation, salt spray, dust, and chemical fumes from reaching the copper and solder joints, which can cause corrosion, leakage currents, or short circuits.

Against Mechanical Stress: It adds a small degree of physical protection against minor scratches, abrasion, and vibration.

Against Environmental Stress: It helps prevent "dendritic growth"—a phenomenon where tiny metal filaments grow between traces in damp conditions, causing failure.

Not all coatings are the same. Choosing one is a balance of protection needs, process requirements, and cost.

1. Acrylic Resin (AR)

The Quick-Dry All-Rounder: Dries fast, offers good moisture and fungal resistance, and is relatively easy to apply and, importantly, remove for repairs.

Feels Like: A clear, hard-drying varnish. It's the go-to for many consumer and industrial applications where rework might be needed.

Watch For: It can be slightly brittle and may not be the best for high-vibration environments.

2. Silicone Resin (SR)

The Flexible Performer: Extremely flexible and elastic, with excellent performance across a wide temperature range (-55°C to +200°C). Great for thermal cycling and high-vibration applications.

Feels Like: A soft, rubbery gel. It’s often used in automotive, aerospace, and high-power LED lighting where components get very hot and expand.

Watch For: It can be more difficult to repair and has a "tacky" feel that might attract dust.

3. Urethane (Polyurethane, UR)

The Heavy-Duty Chemically Resistant: Provides superb resistance to chemicals, solvents, and abrasion. Forms a very tough, durable film.

Feels Like: A hard, tough plastic shell. Ideal for PCBs in harsh industrial or automotive under-hood environments.

Watch For: Very difficult to remove for repair, often requiring special solvents.

4. Parylene (XY)

The Premium Vapor-Deposited Shield: Applied in a vacuum chamber as a gas, it forms a ultra-thin, pinhole-free, and perfectly conformal film. Offers exceptional dielectric strength and biocompatibility.

Feels Like: An invisible, molecular-level barrier. Used for the most demanding applications like military, medical implants, and deep-space electronics.

Watch For: It is a specialized, high-cost process.

Not every board needs one. Ask yourself these questions about your product's end-use:

Will it operate in a humid or condensing environment? (Outdoor sensors, marine electronics, appliances)

Could it be exposed to dust, dirt, or chemical vapors? (Industrial controls, factory equipment, automotive)

Is long-term reliability absolutely critical, even in non-extreme conditions? (Telecom infrastructure, safety-critical systems)

Does it need protection from handling during final assembly? (Finger oils can be corrosive over time)

If you answered "yes" to any, a coating is a wise investment to prevent field failures and costly returns.

How the coating is applied is as important as what is applied. Poor application can leave weak spots (voids) or cover areas that must stay clean (like connectors).

Common methods include:

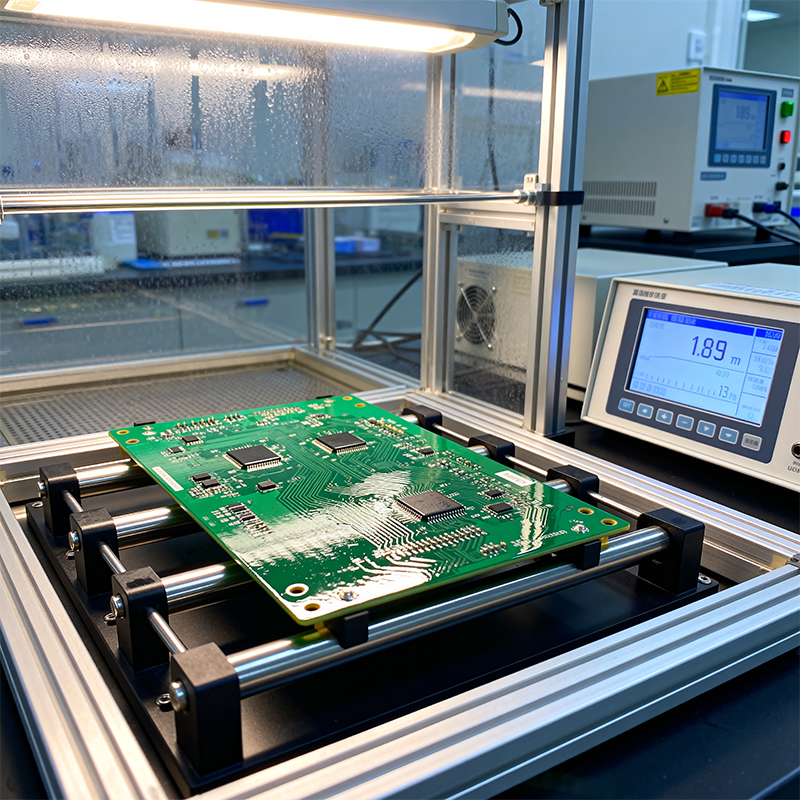

Selective Robotic Coating: The gold standard for production. A machine precisely sprays coating only on pre-programmed areas, avoiding connectors and heat sinks. This ensures consistency and efficiency.

Manual Spraying/Aerosol: Suitable for lower volumes or prototyping. Highly dependent on operator skill.

Dipping: The entire board is dipped, then drained. Good for full coverage but requires careful masking of "keep-out" areas.

This is where a true partner adds value. Applying a conformal coating isn’t a standalone step; it’s the culmination of a controlled process.

A manufacturer like Kaboer, with its integrated factory in Shenzhen, approaches coating as a system:

Pre-Coating Prep: The board must be immaculately clean. Any residual flux or contaminants will be sealed under the coating, potentially causing long-term corrosion. Our cleaning processes ensure a perfect surface.

Precision Masking: Using laser-cut tapes or custom fixtures, we meticulously protect connectors, switches, and test points that must remain uncoated for functionality.

Process Control: We control the coating environment (viscosity, humidity, temperature) and application parameters to guarantee the specified film thickness and uniformity.

Quality Verification: We verify coating coverage and thickness to ensure there are no thin spots or bubbles that would compromise protection.

By managing the entire flow from assembly to coating under one roof, we eliminate the risk and delay that comes from shipping bare boards to a third-party coater. More importantly, we take unified responsibility for the final, protected quality of your assembly.

The coating on your PCB is a strategic form of insurance. For a modest added cost, it dramatically increases your product's resilience against the real-world conditions that standard boards aren't built to handle alone.

It’s the final, invisible shield that allows you to ship your technology with confidence, knowing it’s protected from the inside out. When evaluating its need for your product, think beyond the initial lab test and consider the environment where your device will live its life. Partnering with a manufacturer who understands this protection as an integral part of the build process is the surest way to deliver that confidence to your end customers.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..