Date: 2026-01-26

Imagine you're designing a city. You've laid out streets (circuit traces) perfectly on one map layer. But then you need a highway to connect a street on the north side of the city directly to one on the south side, and they're on different levels. You wouldn't just stop—you'd build a tunnel or a bridge. In the world of printed circuit boards (PCBs), that essential connector is called a via.

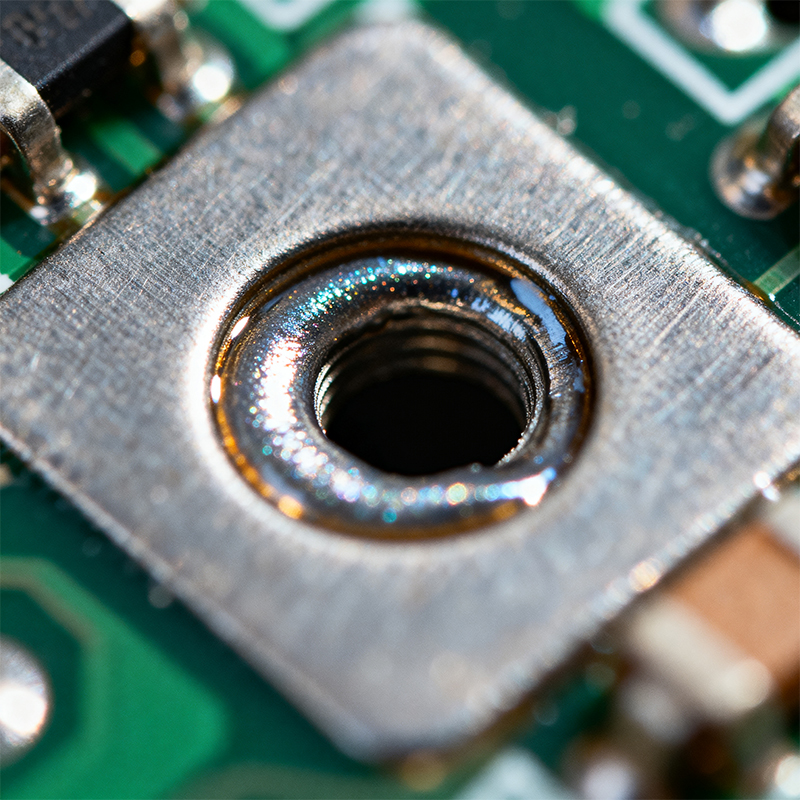

A PCB via (short for "vertical interconnect access") is essentially a tiny, plated hole that allows an electrical signal to pass from one layer of a circuit board to another. If traces are the highways on a single layer, vias are the on-ramps, off-ramps, and multi-level interchanges that create a fully functional, three-dimensional circuit network.

Without vias, complex electronics would be impossible. We'd be stuck with single-layer boards, drastically limiting functionality. Let's look at how these small features make a big difference.

A via isn't just an empty hole poked through the board. It's a carefully manufactured copper-plated cylinder. Here’s a simplified view of how it's created:

Drilling: First, a tiny hole is drilled through the layers of the PCB. For standard vias, a mechanical drill is used. For extremely small vias, lasers do the drilling.

Plating: Next, the inside wall of this hole is chemically coated with a thin layer of copper through a process called electroless copper deposition, followed by electroplating to build up the thickness. This makes the hole electrically conductive.

Filling or Capping (Optional): In many modern designs, especially for surface mounting chips, the via hole is filled with a non-conductive or conductive epoxy and then capped with copper. This prevents solder from flowing down the hole during assembly and provides a flat surface for components.

Not all connections are the same, so engineers use different types of vias.

Through-Hole Via (The Standard)

This is the most common and easiest to manufacture. It's drilled from the top layer all the way through to the bottom layer. Think of it as a public elevator that goes from the roof to the basement, stopping at every floor. It's reliable and strong, but it uses up space on every single layer it passes through, which can get in the way of routing other traces on the inner layers.

Blind Via

A blind via connects an outer layer (top or bottom) to one or more inner layers, but it does not go all the way through the board. Imagine a private staircase connecting the penthouse to the executive suites on the floor just below it. It starts on the top and ends inside the structure. This saves precious space on the inner layers and the opposite outer layer, which is crucial for dense, modern chip packaging.

Buried Via

A buried via connects two or more inner layers only. It starts and ends inside the board and is completely invisible from the outside. This is like a secret passageway connecting two interior floors. It's used in the most complex, high-density boards (like smartphones) to maximize routing space on the outer layers where components are placed.

While their primary job is electrical connection, vias play other critical roles:

Heat Management (Thermal Vias): Have a component that runs hot, like a processor or power regulator? Designers often place a cluster of vias directly under it. These thermal vias act like a chimney, pulling heat down from the surface and spreading it into inner copper planes or out to the other side of the board where a heatsink can be attached.

Signal Integrity & High-Speed Design: At very high frequencies, a via is not a perfect conductor. It acts like a tiny antenna, introducing a small amount of inductance and capacitance. For most signals, this is irrelevant. But for high-speed data lines (like in a processor or DDR memory), the placement and number of vias must be carefully planned to avoid degrading the signal.

Using vias effectively requires some forethought:

Cost and Complexity: Adding more vias increases fabrication time and cost. Blind and buried vias require additional drilling and lamination steps, making them significantly more expensive than simple through-hole vias.

Reliability: The plating inside the via must be uniform and free of voids. Poor plating can crack under thermal stress, leading to an intermittent or failed connection—a very difficult problem to diagnose.

The "Via-in-Pad" Technique: For the finest-pitch ball grid array (BGA) chips, designers sometimes place a via directly in the component's solder pad. This is a advanced technique that requires precise filling and capping to prevent soldering issues, but it's essential for escaping signals from dense chips.

The humble PCB via is a cornerstone of modern electronics design. It's the fundamental feature that allows us to build complex, multi-layered, and high-performance circuits in a compact space. Understanding the different types of vias and their impacts—not just electrical, but also thermal and mechanical—is key to creating reliable, manufacturable, and cutting-edge electronic products. They may be small, but they are the critical vertical connectors that make our two-dimensional board designs into three-dimensional realities.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..