Date: 2025-11-04

Let me give you the straight story about these two terms everyone in electronics keeps throwing around.

So here's the deal:

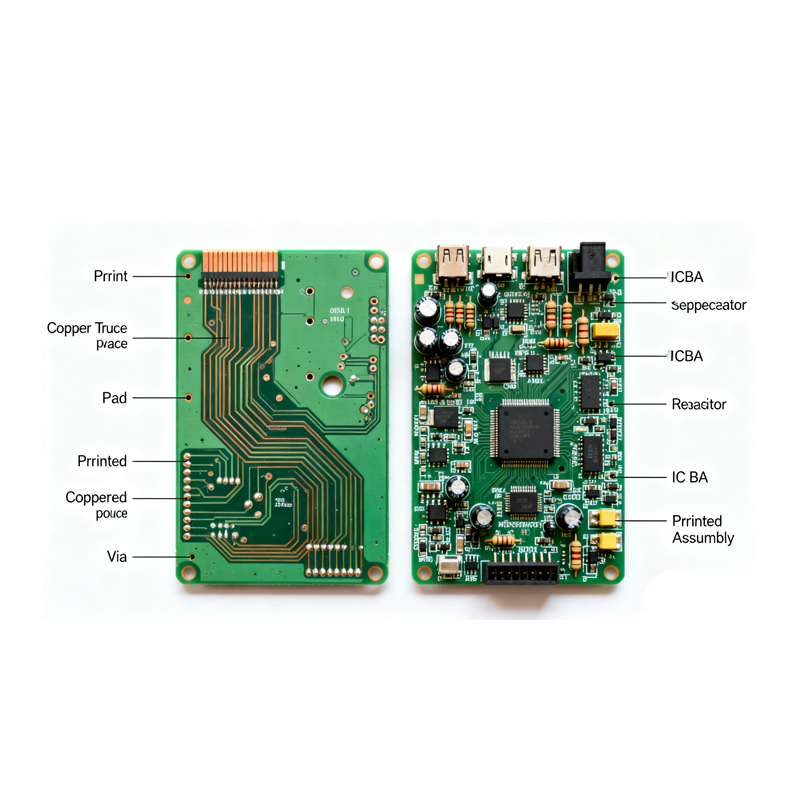

PCB - The Empty Board

Picture a flat green board with copper lines on it. That's a PCB. It's like having a road map without any cars or buildings. The board has:

The base material (usually that green stuff)

Copper traces (the "roads" for electricity)

Holes and pads where parts will eventually go

Protective coating

White printing showing where components belong

But here's the key - if you plug in a bare PCB, absolutely nothing happens. It's just a piece of fiberglass with some metal on it.

PCBA - The Working Board

Now take that same board and add all the tiny components - resistors, chips, capacitors, everything. That's PCBA. This is when the board actually starts doing something useful.

We make PCBA by:

Taking the bare PCB

Loading it into our machines

Placing all the components in the right spots

Running it through ovens to melt the solder

Testing that everything works properly

Why You Should Care

I've seen people get this wrong and it costs them time and money. If you need:

Just the bare boards → order PCB

Complete working boards → order PCBA

Last month, a customer ordered PCBs when they really needed assembled boards. They ended up with a bunch of useless bare boards and had to pay extra to get them assembled later.

The Quick Version

PCB = empty board (can't do anything)

PCBA = complete board (ready to work)

Think of it like this: PCB is the canvas, PCBA is the finished painting. One has potential, the other is actually doing its job.

When you're talking to your circuit board supplier, make sure you're clear about which one you need. It'll save you from headaches down the road.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..