Date: 2025-10-25

Let's talk about something every automotive engineer fears: intermittent electrical failures that disappear during diagnostics. If you're dealing with random infotainment resets or sensor dropouts in smart cockpit systems, the culprit is likely vibration-induced wiring detachment. After helping numerous Tier 1 suppliers solve these issues, we've found that the solution lies not in better connectors, but in eliminating connectors altogether through advanced flexible PCB lamination technology.

Modern vehicles generate constant vibration from multiple sources - engine harmonics, road imperfections, and even audio system bass. This isn't just about comfort; it's about reliability. Traditional wiring solutions fail here for several concrete reasons:

Connectors Work Themselves Loose

Every connector in your system is a potential failure point. The vibration in a typical vehicle cabin can literally shake connectors apart over time. We've seen instances where board-to-board connectors in dashboard systems showed measurable resistance increases after just 1,000 miles of testing.

Layer Separation in Conventional PCBs

Standard multi-layer boards use adhesive systems that simply can't handle the constant stress. The bond between layers weakens over time, leading to intermittent connections that are notoriously difficult to diagnose.

The Cable Fatigue Problem

Individual wires in harnesses act like strings - they vibrate at specific frequencies, eventually suffering from work hardening and fracture. This is particularly problematic where cables transition between fixed points.

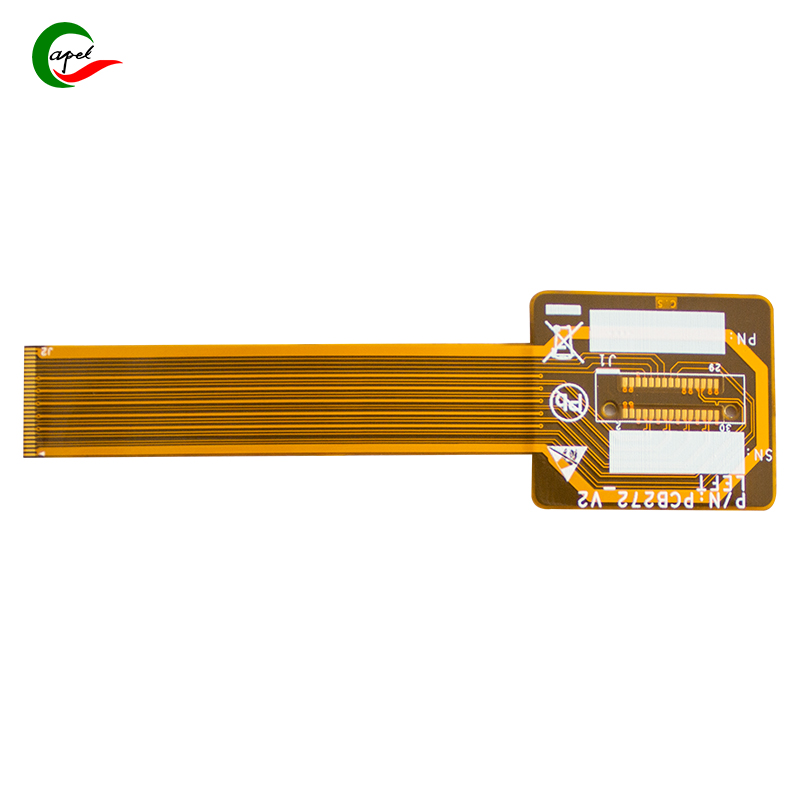

We approach this problem from the material level up. Our flexible PCB lamination process creates a monolithic structure that behaves completely differently under vibration:

True Molecular Bonding

Unlike mechanical fasteners or basic adhesives, our high-temperature, high-pressure lamination process actually fuses the polyimide layers and copper traces into a unified structure. The peel strength we achieve (typically 1.8-2.2 N/mm) means the layers simply can't separate under normal vibration conditions.

Eliminating Failure Points

By integrating what would normally be multiple connected components into a single flexible circuit, we remove the very elements that cause problems. No connectors means no connector failures. No separate wires means no wire fatigue.

Engineering the Material for Vibration

We use rolled annealed copper rather than electrodeposited copper because its grain structure handles repeated flexing better. The polyimide substrates we specify maintain their properties across the entire automotive temperature range (-40°C to 125°C).

Based on our experience across multiple vehicle platforms, here are the key considerations for implementing vibration-resistant flexible PCBs:

Material Selection is Critical

Use high-Tg polyimide (≥260°C) for the substrate

Specify rolled copper for dynamic flex applications

Avoid epoxy-based adhesives - they become brittle with thermal cycling

Process Control Makes the Difference

The lamination process requires precise control:

Temperature: 190°C ±5°C

Pressure: 2.0-2.5 MPa

Time: 75-90 seconds at peak conditions

Deviating from these parameters can result in inadequate bonding or material degradation.

Design for Vibration from the Start

Route traces perpendicular to primary bending axes

Use curved corners instead of sharp angles

Place components away from high-stress areas

Consider the vibration modes of the entire assembly

The data from field implementations tells the story clearly:

One luxury automaker reduced smart cockpit wiring-related warranty claims by 78% after switching to our laminated flexible PCBs for their infotainment backbone.

An electric vehicle manufacturer eliminated 23 connectors from their center console controls by using a single laminated FPC, resulting in a 40% space saving and zero vibration-related failures in 100,000-mile durability testing.

A commercial vehicle manufacturer solved persistent display flickering issues in their heavy truck dashboards by replacing conventional wiring with our vibration-optimized flexible circuits.

If you're designing smart cockpit systems, consider flexible PCBs with proper lamination processes when:

Your system experiences vibration above 5g

You have multiple interconnection points

Reliability over 10+ years is required

Space is constrained

The investment in proper flexible PCB technology typically pays for itself through reduced warranty costs and improved customer satisfaction.

Dealing with vibration-related failures in your current designs? Our engineering team can analyze your specific application and provide concrete recommendations. We'll show you exactly how our lamination process can solve your detachment problems.

related link:

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..