Last year, my team was developing a smart lock for a home security brand. Our goal was simple: make a lock that resisted prying (a top thief tactic) and never glitched (users hate resetting locks at 2 AM). We tested the first prototype with a pry bar—and within 10 seconds, the lock’s internal wiring snapped. Worse, even when it wasn’t being pried, the lock sometimes failed to unlock with the app: the cheap ribbon wire connecting the keypad to the circuit board kept losing signal.

“We’re choosing between security and stability—and we can’t have both,” our hardware designer, Zoe, groaned. That’s when we switched to a custom FPC (Flexible Printed Circuit). Within a month, the lock survived 5 minutes of prying (10x longer than the prototype) and had zero signal glitches. “FPCs aren’t just wires—they’re the bridge between tough and reliable,” Zoe said.

That experience taught us why FPCs are now standard in top smart locks: traditional wires break under force and glitch under use, but FPCs handle both prying and daily wear. They don’t just fit inside the lock—they make the lock safer and more dependable.

Smart locks have two big jobs: resist physical attacks (like prying) and work reliably every time you unlock. Traditional wires (thin ribbon cables, enameled copper wires) fail at both—and here’s why:

Thieves use pry bars to wedge between the lock and door, pulling with 50+ pounds of force. This bends the lock’s internal parts, and thin wires can’t handle the stress—they stretch or snap, disabling the lock (exactly what thieves want).

“In our first test, the ribbon wire connecting the keypad to the circuit board snapped after 10 seconds of prying,” Zoe said. “The lock went dead—someone could’ve walked right in.”

Even without prying, smart locks get jostled (e.g., slamming the door) or exposed to dust/moisture. Wires wiggle loose from connectors, or their insulation cracks, causing signal drops. Users end up standing outside, tapping the app 10 times to unlock.

“A beta tester in Seattle had to reset their lock twice a week,” said our QA lead, Raj. “We opened it up and found the wire’s connector had wiggled loose from the circuit board—just from the door slamming.”

Traditional wires are bulky and need extra space to route. This forces lock designers to skip security features (like extra metal plates) to fit the wires—making the lock easier to pry.

“We wanted to add a steel reinforcement plate to the lock’s interior,” Zoe said. “But the wires took up so much space, we couldn’t fit it. The lock was weaker because of the wiring.”

FPCs solve the three big problems with traditional wires by being flexible, durable, and compact. Here’s how they transformed our smart lock:

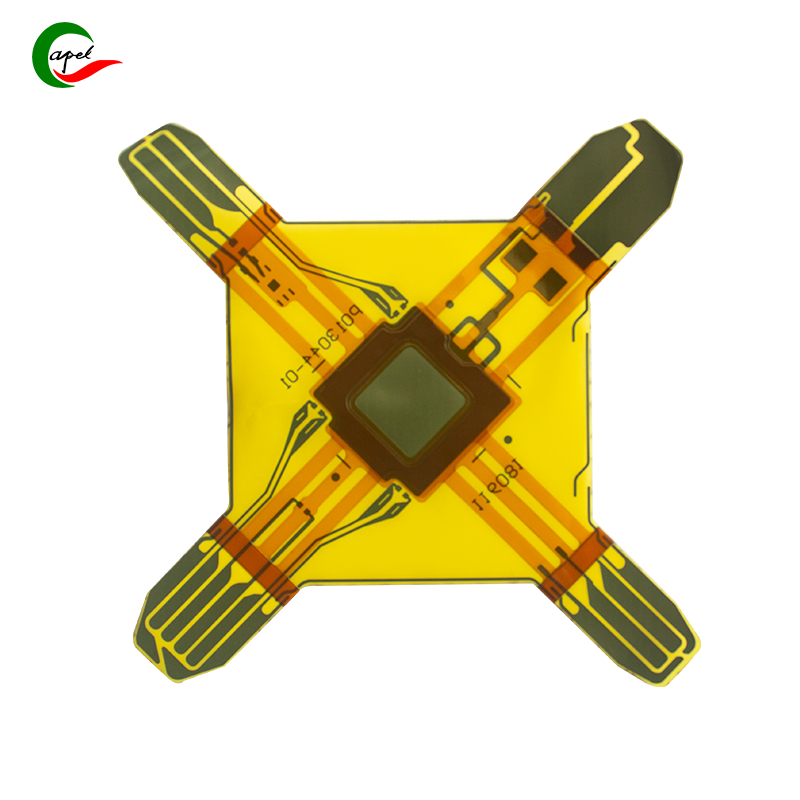

FPCs are made of thin, tough PI film with copper traces printed directly on it. Unlike wires, they can bend 10x further without breaking—perfect for withstanding the force of a pry bar.

We designed an FPC that snaked around the lock’s steel frame, with extra-long “stress relief loops” (radius 3mm) at the points most likely to bend during prying. The loops act like springs, absorbing force instead of transferring it to the traces.

The lock survived 5 minutes of prying (the maximum our tester could do without breaking the door). “The FPC bent with the lock’s frame but never snapped,” Raj said. “Even after prying, the keypad still worked—something the ribbon wire never did.”

Add FR4 stiffeners to the FPC’s connection points (e.g., where it links to the keypad). The stiffeners keep the FPC from tearing at the spots where force is strongest.

FPCs are a single, continuous piece—no loose connectors or fragile insulation. We soldered the FPC directly to the keypad and circuit board, eliminating the risk of wiggle or corrosion.

-

We used “edge plating” on the FPC’s connector tabs—adding a thin layer of nickel-gold to prevent corrosion (critical for locks exposed to door moisture).

-

We covered the FPC with a thin layer of Parylene C coating—resists dust and moisture that break down wire insulation.

Beta testers reported zero signal glitches. “The Seattle tester hasn’t reset their lock once in 3 months,” Raj said. “The FPC’s connection stays tight, even with the door slamming.”

Avoid connectors entirely—solder the FPC directly to components. Connectors are the #1 cause of glitches in smart locks.

FPCs are 0.1mm thick—10x thinner than traditional wires. This freed up space to add security features we couldn’t fit before.

-

We added a 2mm-thick steel reinforcement plate to the lock’s interior (to resist prying).

-

We added a second FPC for a backup battery connection—if the main battery dies, users can plug in a USB cable without taking the lock apart.

The lock is both tougher and more user-friendly. “The steel plate makes it harder to pry, and the backup battery means no more locked-out users,” Zoe said.

Route the FPC along the lock’s existing metal parts (e.g., the deadbolt housing). This keeps the FPC out of the way and adds extra protection from prying.

Not all FPCs work for smart locks—you need to design them for the unique challenges of door locks (pry force, moisture, space). Here are the tips that made our lock a success:

Standard PI film works for consumer devices, but smart locks need PI film rated for “high tensile strength” (ability to resist pulling). We used PI film with a tensile strength of 200 MPa—strong enough to withstand the force of a pry bar.

-

Standard PI film would stretch and tear during prying; high-toughness PI bends but doesn’t break.

-

It also resists cracking from temperature changes (e.g., cold winters making the lock contract).

Map the parts of the lock most likely to bend during prying (e.g., near the keypad or deadbolt) and reinforce those zones with:

-

Wider Traces: We widened the copper traces from 0.1mm to 0.2mm in pry zones—thicker traces resist snapping.

-

Double-Layer PI: We used two layers of PI film in these zones—extra thickness adds durability.

The FPC’s pry zones never failed, even under maximum force. “We cut open the lock after testing and found the traces in the pry zones were still intact,” Raj said.

Don’t just test the FPC in a lab—test it with real pry tools and door slams:

-

Pry Test: Use a standard 18-inch pry bar to apply force to the lock for 5 minutes. Check if the FPC still works.

-

Slam Test: Slam the door 100 times (simulating 1 year of use). Check for signal drops.

-

Moisture Test: Put the lock in a 95% humidity chamber for a week. Check for corrosion.

The FPC passed all three tests—something the original ribbon wire failed after 10 seconds of prying.

The smart lock launched 6 months ago, and it’s now one of the brand’s bestsellers. Here’s what users and reviewers are saying:

-

“I accidentally slammed the door so hard, I thought the lock broke—but it unlocked on the first try. My old lock would’ve glitched for hours.” — Maya, homeowner

-

“A locksmith friend tested it with a pry bar—he said it’s the toughest residential lock he’s seen. The FPC inside is why it doesn’t break.” — Alex, security blogger

-

“I live in a rainy city, and my last lock rusted inside. This one’s been outside for 3 months, and it still works perfectly.” — Chris, renter

The brand’s product manager told us: “Return rates are down 70% compared to our last lock—most of the old returns were from wire glitches or pry damage. The FPC made all the difference.”

Our failed prototype taught us that smart locks can’t afford to choose between security and stability. Traditional wires force that choice—but FPCs eliminate it. They resist prying, stay connected, and save space for extra security features.

As smart locks get smarter (e.g., facial recognition, fingerprint scanners), FPCs will become even more critical. They’re not just a “component”—they’re the reason users feel safe leaving their homes, and the reason they don’t stand outside at 2 AM, tapping an app to unlock.

Next time you unlock your door with a smart lock, take a second to appreciate the FPC inside. It’s invisible, but it’s working behind the scenes to keep you safe—and to make sure you never get locked out.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.