Date: 2026-01-14

When engineers design circuit boards, thickness selection is often an afterthought, but this parameter directly impacts product performance, reliability, and cost. Like choosing a building's foundation, PCB thickness determines the entire structure's stability and durability.

If you ask any PCB manufacturer their default thickness, 90% will say "1.6mm." This standard didn't happen by accident—it's the optimal balance point validated through decades of practice:

Provides sufficient mechanical strength to prevent warping during production

Suitable for soldering and mounting most components

Offers the best cost-effectiveness with ample raw material supply

Compatible with standard connectors and enclosure designs

Interestingly, 1.6mm (approximately 1/16 inch) originated from the imperial system but was widely adopted globally. Even in the United States, where imperial units are commonly used, the PCB industry generally accepts this metric value.

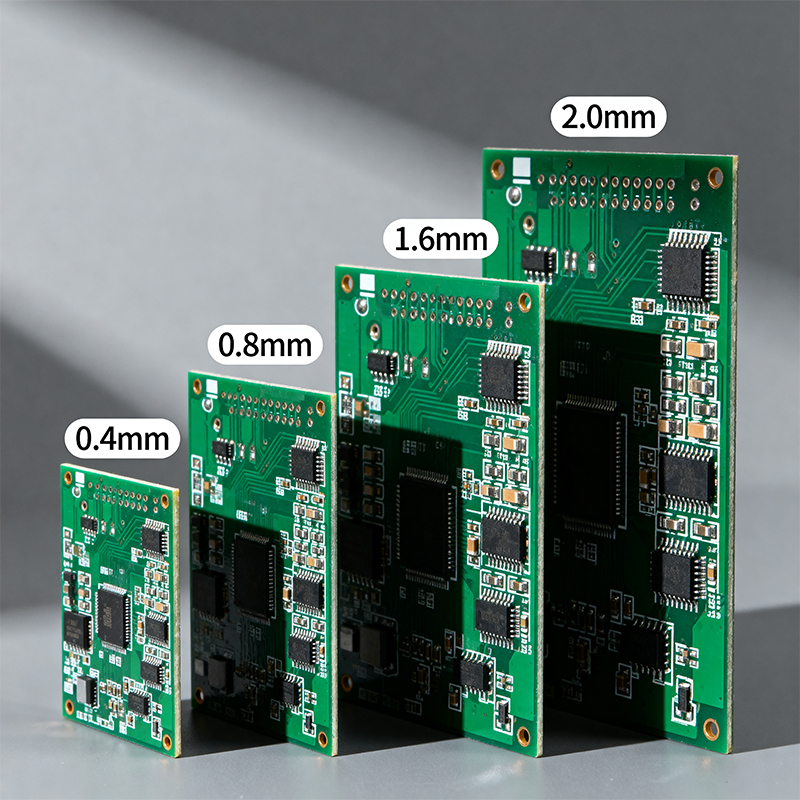

0.4mm: The thinnest rigid boards, for extreme space constraints

0.6mm: Common in memory modules, small sensors

0.8mm: Smartphone internal modules, wearable devices

1.0mm: USB devices, small controllers, IoT modules

1.2mm: Slightly thinner general-purpose option

1.6mm: Industry default standard (most widely used)

2.0mm: Applications requiring extra strength

2.4mm: Industrial control boards, devices with heavy connectors

3.0mm and above: Power equipment, backplanes, high-reliability applications

How much physical stress must the board withstand? Consider:

Number and location of screw mounting points

Insertion/extraction forces of connectors

Vibration and shock during device use

Board size (larger boards need greater thickness to prevent bending)

Impedance control: Thickness affects dielectric height, influencing characteristic impedance

Heat dissipation capability: Thicker boards have greater thermal mass

Interplane capacitance: Distance between power and ground planes affects high-frequency decoupling

Thermal stress during assembly

Compatibility with automated handling equipment

Adaptability to test fixtures

Weight limitations of the final product

Standard thicknesses (particularly 1.6mm) typically offer the lowest cost because:

Raw material inventory is plentiful

Production processes are mature

Yield rates are highest

No special equipment or setups are needed

Certain industries have developed their own thickness standards:

Computer expansion cards: Typically 1.6mm

Automotive electronics: Often 1.6-2.0mm

Military/aerospace: Varies by specification, generally thicker

Actually, all PCBs have thickness tolerances, typically ±10%. For a 1.6mm board, anything between 1.44-1.76mm is normal. Precision applications require early consultation with manufacturers about their capabilities.

While additional layers do increase thickness, using thinner dielectric materials can keep an 8-layer board around 1.6mm. Thickness depends more on insulating material than the number of copper layers.

For high-speed signals, dielectric thickness directly impacts impedance. Changing thickness may require recalculating trace widths to maintain target impedance values.

When unsure how to choose, follow this decision process:

Ask Three Basic Questions First:

How large is the circuit board?

What environment will it be installed in?

What's the budget?

Reference Similar Products:

Examine successful designs from competitors or similar applications

Early Communication with Manufacturers:

Consult about production feasibility before starting layout

Prototype Verification:

If uncertain, start with standard thickness for prototype testing

Special Attention Points:

Controlled impedance designs: Determine thickness early

High-power devices: Consider thermal requirements

High-vibration environments: May require increased thickness

Typically 0.1-0.3mm thick, selected based on bend radius and dynamic flex cycles.

Used in heat-sensitive applications like high-power LEDs, with thickness determined by both insulating and metal base layers.

May require specific thicknesses of low-loss materials to meet performance targets.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..