Date: 2026-01-03

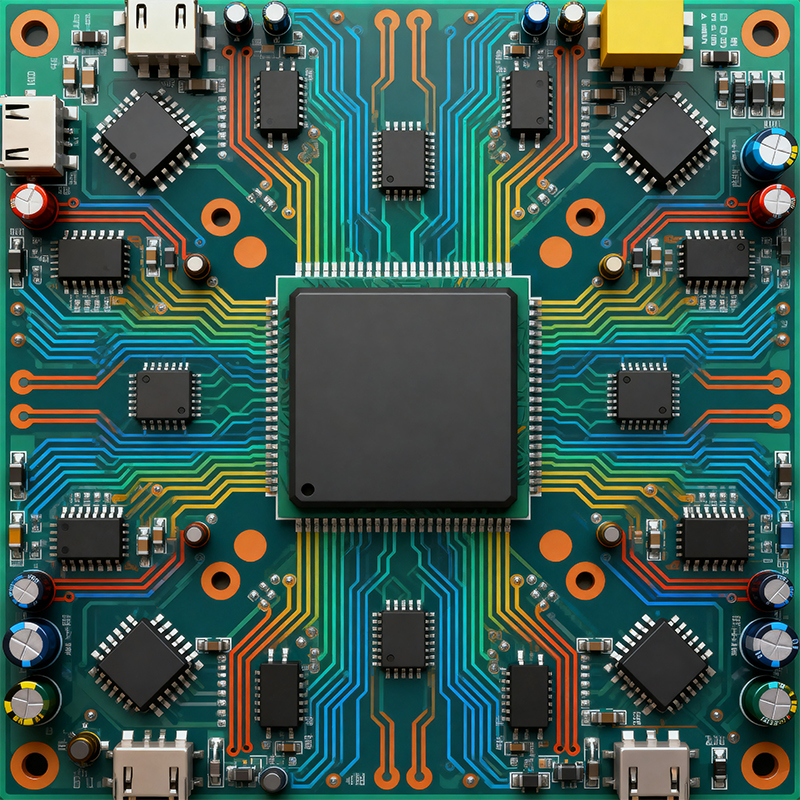

When you think of a "circuit board," you might picture a green board with silver solder points. But in electronics manufacturing, the real heart is the PCBA (Printed Circuit Board Assembly). Simply put, it’s the entire process that transforms a "blank" PCB (Printed Circuit Board) into the functional brain of your device.

Imagine this: You've designed a sleek smart thermostat with a beautiful interface, but it needs to "think" and "react"—to sense temperature, drive the display, and connect to Wi-Fi. All these functions rely on a PCBA, where all the tiny electronic components (chips, resistors, capacitors, connectors, etc.) are precisely mounted and connected to the PCB. It's the physical realization of your design intent—the engineering bridge between your idea and a market-ready product.

At Kaboer, our factory in Shenzhen treats PCBA manufacturing as a precision craft. It’s a connected process where each step matters. Here’s how it typically works in our day-to-day operations:

The work begins long before any component is placed. Our engineering team can collaborate with you on DFM (Design for Manufacturability) analysis. Think of it like reviewing blueprints before building a house—we’ll evaluate your PCB design files to spot potential issues that could cause production delays or quality risks (like components placed too close, or pads that are hard to solder). We then provide suggestions to optimize your design, ensuring it’s both high-performance and easy to manufacture with quality and efficiency.

This is where production starts. Using high-precision stencil printers, we apply solder paste exactly where it’s needed on the PCB—like a careful painter. Then, high-speed pick-and-place machines, with remarkable accuracy and speed, take thousands of tiny surface-mount devices (SMDs) from reels and place them onto the paste. This process demands extreme stability and a clean environment. Our equipment handles everything from tiny 01005 packages to large BGA chips.

The populated PCB then travels through a reflow oven—a carefully controlled "oven journey" where the solder paste melts and then cools, forming solid electrical and mechanical connections. After this, no board moves forward without inspection. Our AOI (Automated Optical Inspection) systems act like eagle-eyed inspectors, using cameras to quickly scan each PCBA for defects like misaligned components, missing parts, solder bridges, or wrong polarity.

For larger or special components that can’t be surface-mounted (like some connectors or electrolytic capacitors), we perform manual or automated insertion. These boards then go through wave soldering, where the bottom side passes over a wave of molten solder to create reliable connections for these through-hole parts.

This step is crucial to ensure every board you receive works as intended. Depending on your product's complexity, we offer several testing options:

In-Circuit Test (ICT): Using flying probe or bed-of-nails testers to check connectivity and basic component values.

Functional Test (FCT): This is the most direct validation. We connect the PCBA to a test jig that mimics its real working environment and run your provided test programs. We check if it powers on, communicates, and responds to commands correctly.

Burn-in / Aging Test: For products requiring high reliability, we can run the PCBA powered-on in a controlled temperature environment for a set period. This helps identify any early-life potential failures.

Once the PCBA is complete, we can provide further value-added services, such as:

Programming: Loading your software or firmware into the main controller.

Box Build / Final Assembly: Installing the PCBA into your provided enclosure and completing basic cable connections.

Packaging & Logistics: Packing boards in anti-static materials and arranging international shipping according to your supply chain needs.

We know choosing a PCBA manufacturer isn’t just about comparing specs and prices. It’s about trust, communication, and how a partner responds when questions or challenges arise (which can happen in any complex manufacturing process).

Based on our experience collaborating with international electronics brands, here’s what we believe makes a partnership work smoothly:

Direct Communication, Fewer Misunderstandings

Because we own our factory, when you have a question about a process or need to clarify a design detail, your request doesn’t get passed through multiple layers. Often, our project engineer can walk to the production floor, discuss it with the line supervisor, and get back to you with a clear answer or even a real-time photo within hours. This transparency is about keeping you confidently informed.

Translating Your Quality Needs into Our Production Standards

We take time to understand your product’s end use. Is it for a consumer gadget, or an industrial/medical device where reliability is critical? Knowing this context lets us adjust our process controls and inspection focus. We aim to ensure every PCBA we ship meets your specific quality expectations, not just generic industry standards.

Flexibility to Handle Changes

Design revisions during development, or a sudden need to ramp up production due to positive market feedback? We see these situations often. Because we manage our own production schedule and material sourcing, we can be more agile in coordinating resources to help you adapt to unexpected changes, working together to find the most practical solution.

Ultimately, we see ourselves as an extension of your supply chain. Our goal isn’t just to “complete an order,” but to contribute to your product’s success in the market through consistent, reliable manufacturing.

If you’re planning a new hardware project or have uncertainties about your current PCBA supply, we’re happy to have a conversation. Even a casual discussion about technical possibilities, or a preliminary DFM review of your design files, might bring useful insights.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..